Novel composite isolating layer based on biaxial texture metal substrate and preparation method thereof

A composite isolation layer and metal baseband technology, applied in the direction of metal layered products, metal material coating technology, chemical instruments and methods, etc., can solve the problem of poor surface morphology, unfavorable growth of rare earth oxide superconducting layer, texture degree Poor problems, high utilization rate, high process repeatability and reliability, and precise control of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

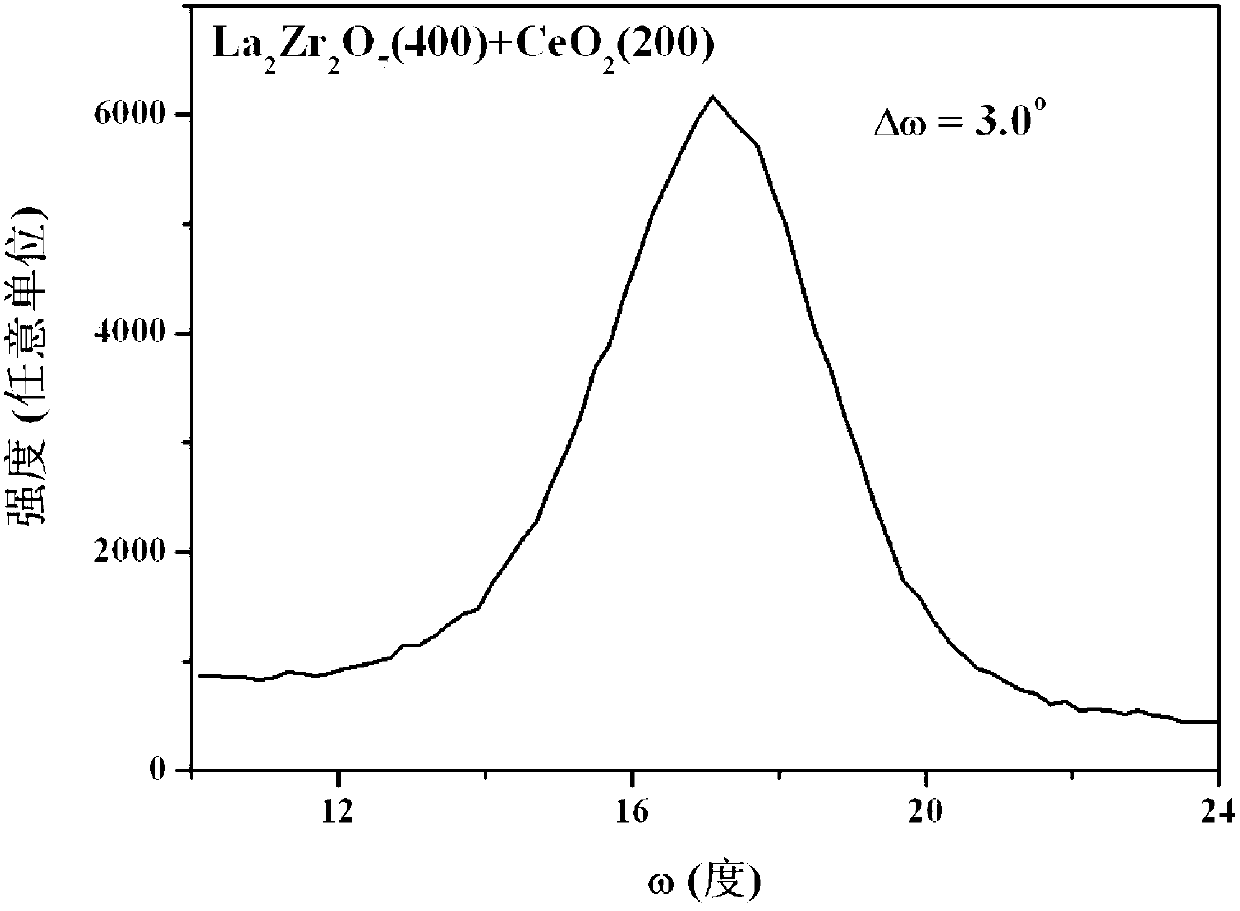

[0050] like figure 1 As shown, the La provided by the present invention 2 Zr 2 o 7 / YSZ / CeO 2 Schematic diagram of the structure of the embodiment of the composite isolation layer, which is based on the La 2 Zr 2 o 7 / YSZ / CeO 2 Composite isolation layer. The composite isolation layer adopts a three-layer structure, the upper layer is La 2 Zr 2 o 7 Isolation layer 1, the middle layer is YSZ isolation layer 2, and the lower layer is CeO 2 Isolation layer 3. Among them, La 2 Zr 2 o 7 The thickness of isolation layer 1 is 50nm, the thickness of YSZ isolation layer 2 is 60nm, CeO 2 The thickness of the isolation layer 3 is 80 nm.

[0051] The present invention adopts radio frequency magnetron sputtering coating method to prepare La 2 Zr 2 o 7 isolation layer, the method includes the following steps:

[0052] Step 1, La with a purity of 4N 2 Zr 2 o 7 The target material is loaded into the radio frequency magnetron sputtering coating system;

[0053] Step 2, t...

Embodiment 2

[0074] like figure 1 As shown, the La provided by the present invention 2 Zr 2 o 7 / YSZ / CeO 2 Schematic diagram of the structure of the embodiment of the composite isolation layer, which is based on the La 2 Zr 2 o 7 / YSZ / CeO 2 Composite isolation layer. The composite isolation layer adopts a three-layer structure, the upper layer is La 2 Zr 2 o 7 Isolation layer 1, the middle layer is YSZ isolation layer 2, and the lower layer is CeO 2 Isolation layer 3. Among them, La 2 Zr 2 o 7 The thickness of isolation layer 1 is 150nm, the thickness of YSZ isolation layer 2 is 20nm, CeO 2 The thickness of the isolation layer 3 is 30 nm.

[0075] The present invention adopts radio frequency magnetron sputtering coating method to prepare La 2 Zr 2 o 7 isolation layer, the method includes the following steps:

[0076] Step 1, La with a purity of 4N 2 Zr 2 o 7 The target material is loaded into the radio frequency magnetron sputtering coating system;

[0077] Step 2, ...

Embodiment 3

[0098] like figure 1 As shown, the La provided by the present invention 2 Zr 2 o 7 / YSZ / CeO 2 Schematic diagram of the structure of the embodiment of the composite isolation layer, which is based on the La 2 Zr 2 o 7 / YSZ / CeO 2 Composite isolation layer. The composite isolation layer adopts a three-layer structure, the upper layer is La 2 Zr 2 o 7 Isolation layer 1, the middle layer is YSZ isolation layer 2, and the lower layer is CeO 2 Isolation layer 3. Among them, La 2 Zr 2 o 7 The thickness of isolation layer 1 is 90nm, the thickness of YSZ isolation layer 2 is 50nm, CeO 2 The thickness of the isolation layer 3 is 60 nm.

[0099] The present invention adopts radio frequency magnetron sputtering coating method to prepare La 2 Zr 2 o 7 isolation layer, the method includes the following steps:

[0100] Step 1, La with a purity of 4N 2 Zr 2 o 7 The target material is loaded into the radio frequency magnetron sputtering coating system;

[0101] Step 2, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com