Double-sided wafer boat, wafer flipping device and wafer flipping method

A flip device, double-sided technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problem of wafer breakage easily, and achieve the effect of avoiding breakage, improving production efficiency, and ensuring productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

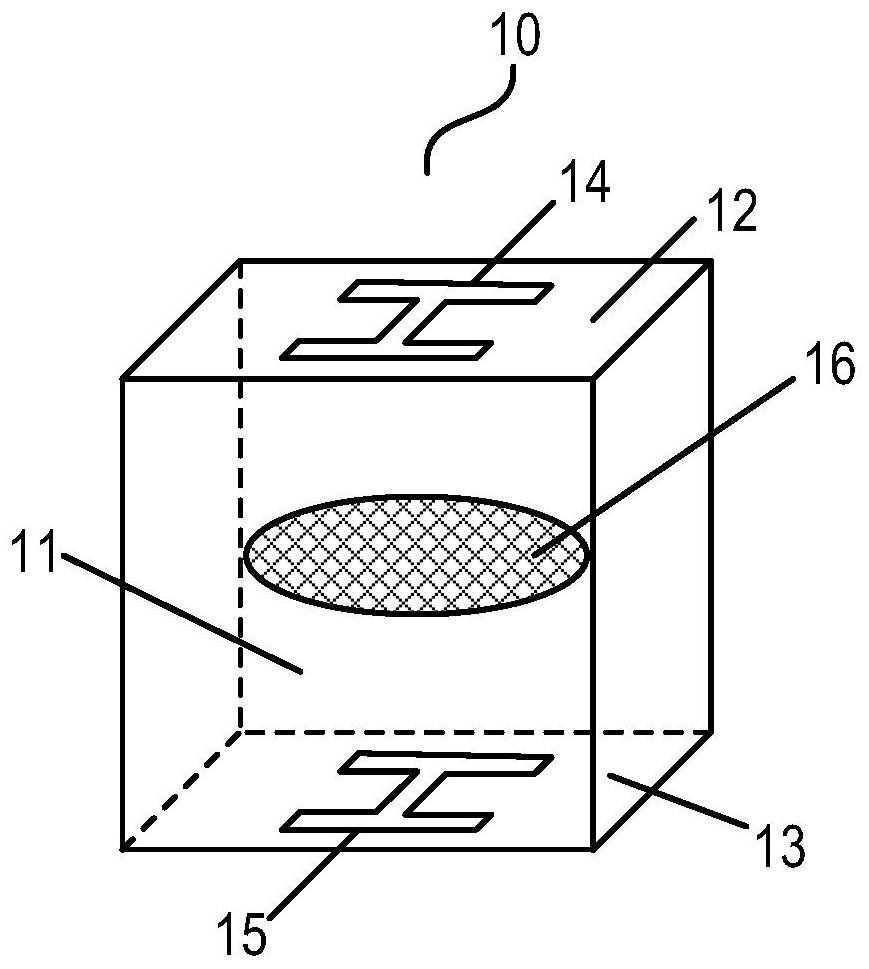

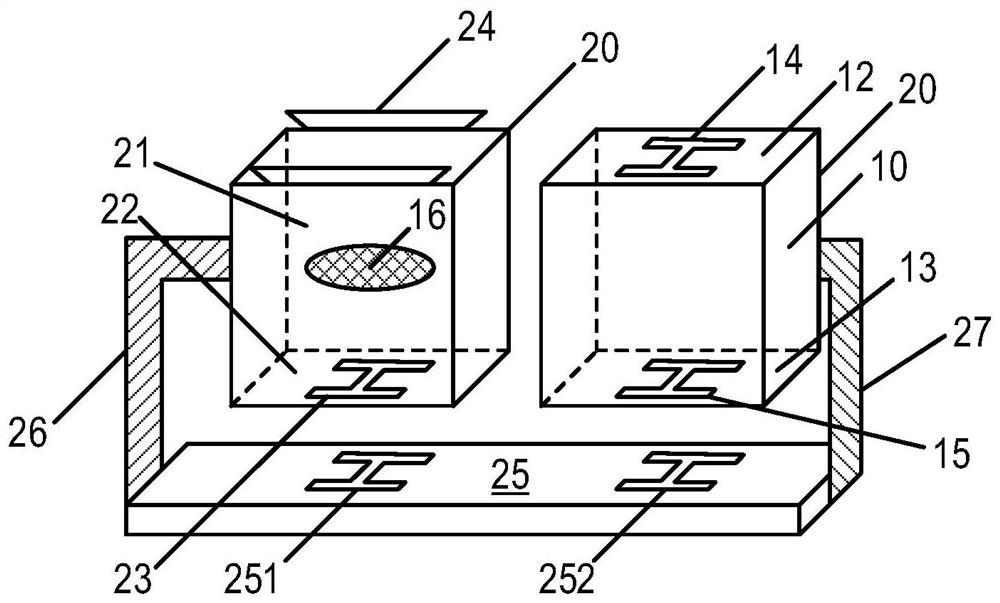

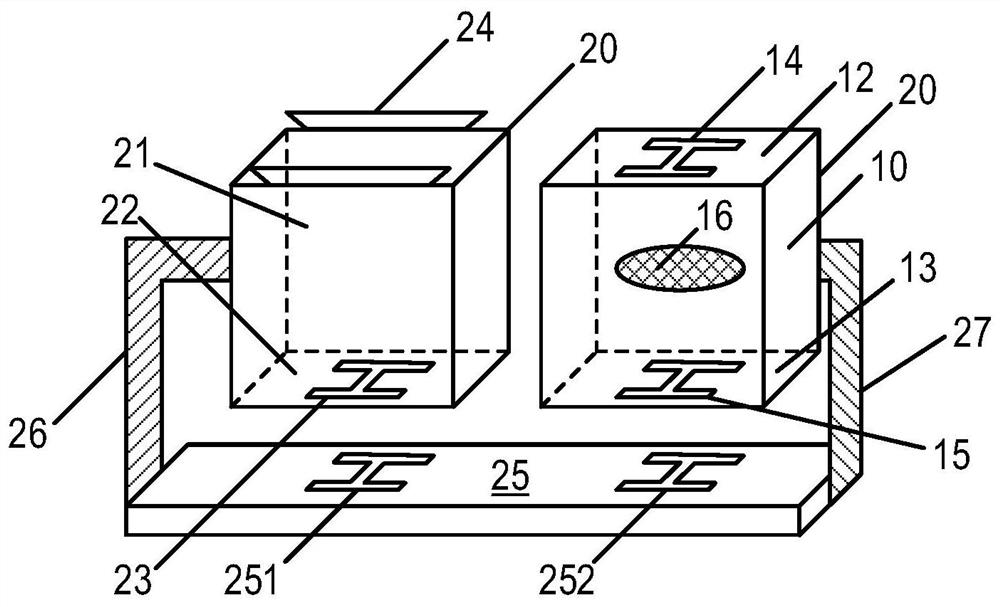

[0031] Specific implementations of the double-sided wafer boat, wafer inversion device and wafer inversion method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In the prior art, the wafer boat is used as the carrier of the wafer, and usually only one side (generally the bottom surface of the wafer boat) is provided with a positioning structure, and the wafer processing machine is provided with an identification structure matching the positioning structure. The mutual matching of the structure and the marking structure defines the position of the wafer boat on the wafer processing machine, on the one hand to ensure the stable placement of the wafer inside the wafer boat, and on the other hand to ensure the smooth progress of the semiconductor processing process. The single-sided wafer boat can only be placed in the wafer processing tool with the surface having the positioning structure as the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com