A corrosion-resistant tail rudder and wind-driven generator

A corrosion-resistant and tail rudder technology, which is applied in the direction of wind turbines, wind turbine control, wind power generation, etc., can solve problems such as the inability to adjust the tail rudder tilt bar, poor corrosion resistance of the tail rudder, and poor fatigue resistance, etc., to achieve Light weight, good bending resistance, and the effect of improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

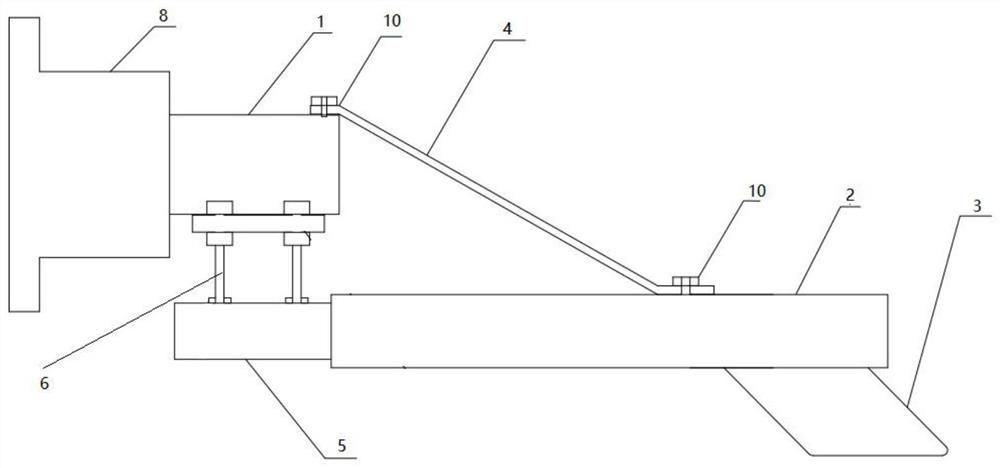

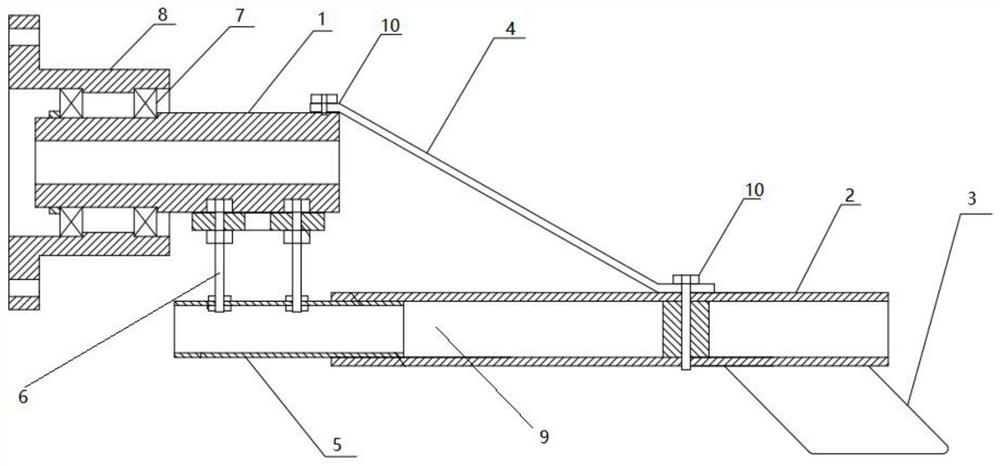

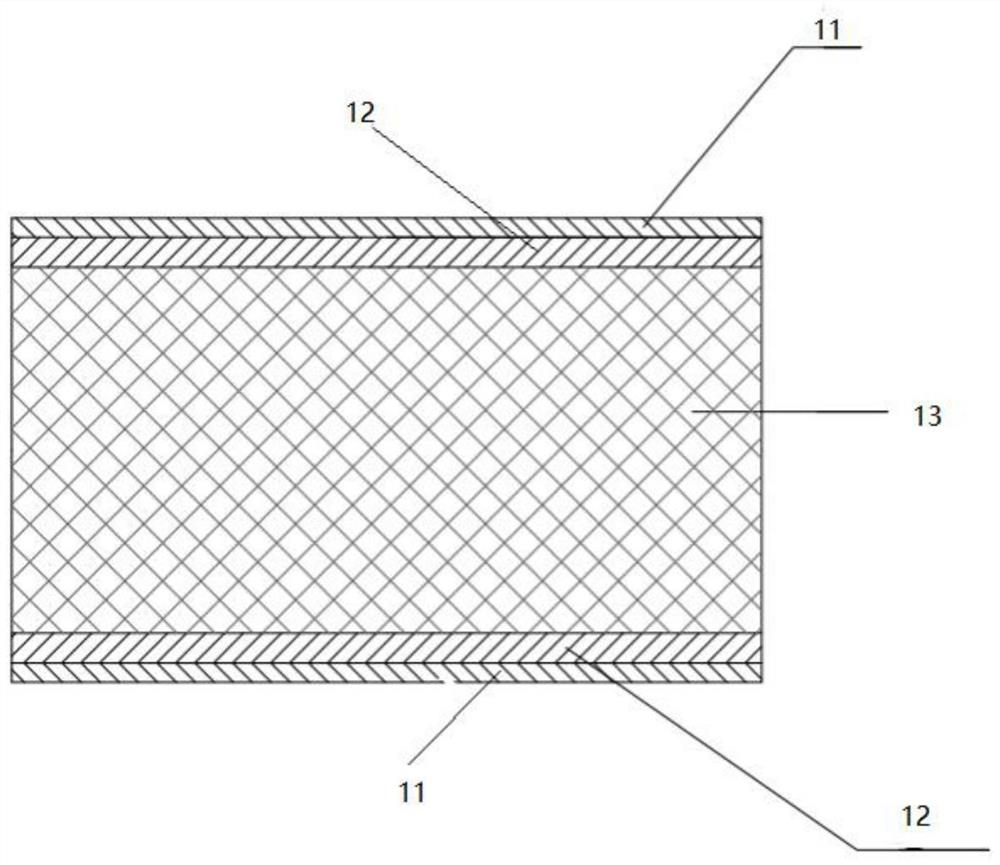

[0034] Please refer to the attached figure 1 , attached figure 2 , Embodiment 1 of the present invention proposes a corrosion-resistant tail rudder, including a connection mechanism, an anti-vibration cable-stay adjustment mechanism, and a tail rudder mechanism;

[0035] The connecting mechanism includes a first connecting piece 1;

[0036] The tail rudder mechanism includes a tail boom 2 and a tail fin plate 3 installed on the bottom surface of the tail boom 2 away from the end of the first connecting piece 1;

[0037] The anti-vibration cable-stay adjustment mechanism includes an adjustable component, a cable-stay rod 4 and a second connector 5 located below the first connector 1 , and one end of the cable-stay rod 4 passes through the upper surface of one end of the first connector 1 . The bolt 10 is fixedly connected, the other end of the diagonal stay rod 4 is fixedly connected with the upper surface of the tail rod 2 through the bolt 10, and one end of the adjustable ...

Embodiment 2

[0051] Please refer to the attached figure 1 , attached figure 2 , attached image 3 , Embodiment 2 of the present invention proposes a wind-driven generator, including a generator, a generator main shaft, a generator cabin, a fan pole, a wind wheel, and a corrosion-resistant tail as described in any one of the above-mentioned Embodiment 1. Rudder, the bearing seat 8 of the tail rudder is connected with one end of the generator cabin through the tail rudder connecting plate. Since the connection structure between the generator, the generator main shaft, the generator cabin, the fan pole, the wind wheel and the tail rudder belongs to the prior art, it will not be described in detail in this embodiment, and those skilled in the art will refer to the prior art that is Yes, and the specific structure of the tail rudder can be referred to the first embodiment above.

[0052] Specifically, in the embodiment of the present invention, the structure of the main shaft of the generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com