Laser cutting equipment

A technology of laser cutting and laser cutting head, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as high cost, inconvenient use, and unsuitable for small and medium-sized enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deepen the understanding and recognition of the present invention, the technical solutions of the present invention will be further described and introduced below in conjunction with the accompanying drawings and embodiments.

[0030] In order to solve the problems of high cost and inconvenient use of existing large-scale laser cutting machines, and save a lot of manpower and material costs, this application takes the cutting of light-weight plates as an example, and designs a CO laser cutting machine suitable for light-weight plates. 2 Laser automatic cutting machine can realize the processing of large-sized light-weight plates.

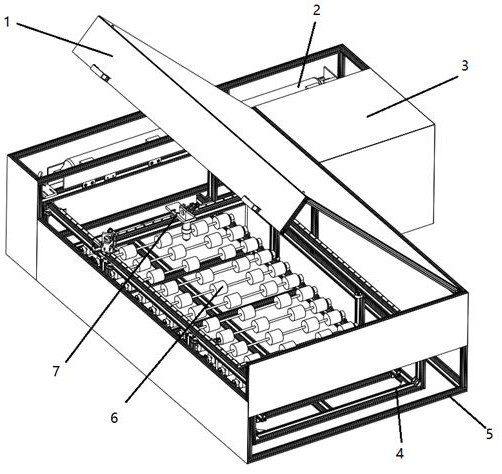

[0031] In the embodiment of the present invention, such as Figure 1-3 As shown, a laser cutting device suitable for lightweight plates is provided, including a top cover 1, a protective casing, an XY support frame 4, a cutting bed 6, a vertical floating mechanism, a laser generating component, an X-axis motion mechanism 7, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com