Shoe press mechanism of paper machine

A technology of shoe press and paper machine, which is applied in the direction of paper machine, paper making, pressing part, etc. It can solve the problems of reduced service life of the endless belt and reduced papermaking operation efficiency, etc., and achieve the effect of prolonged service life and stable paper production for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

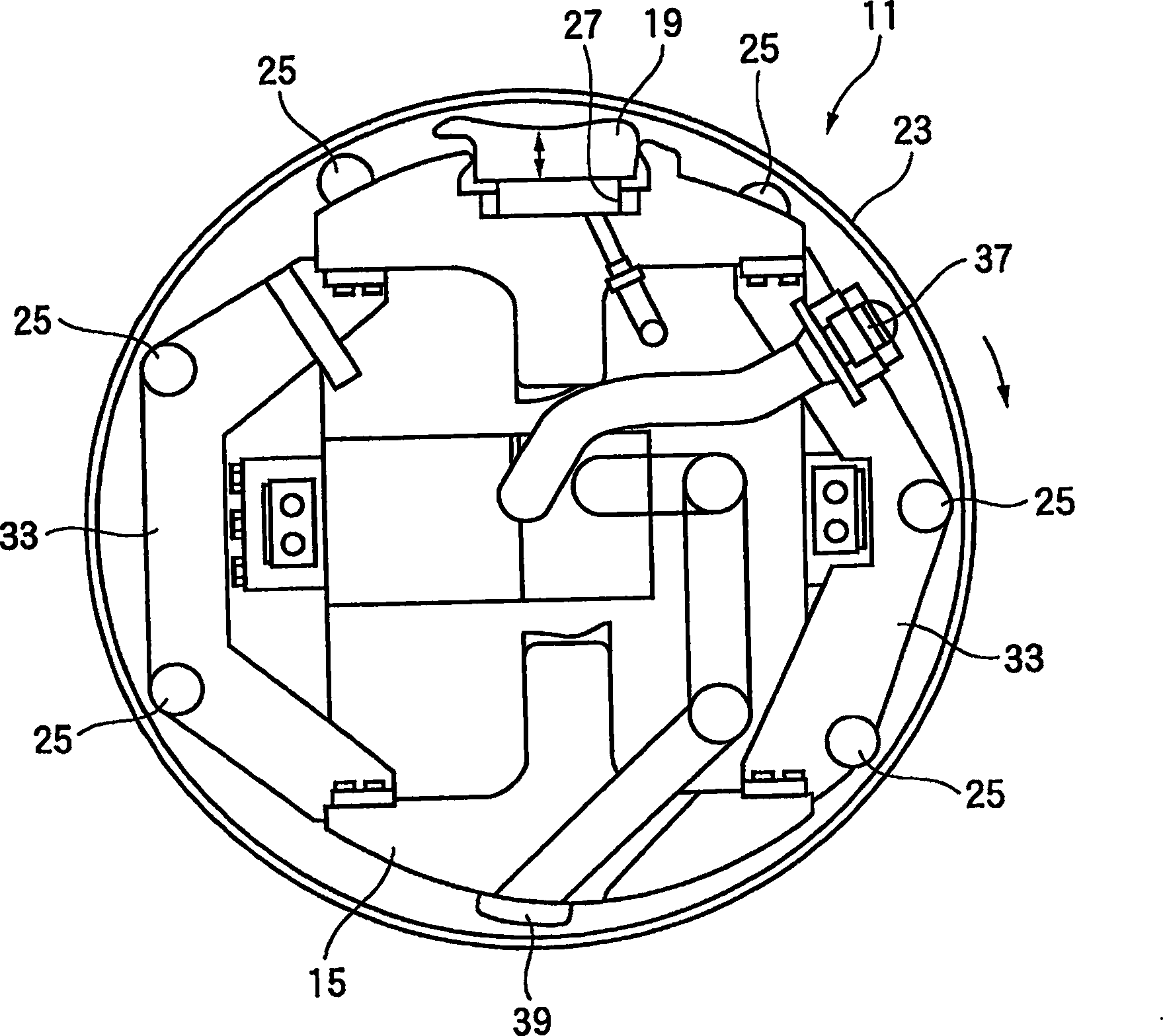

[0028] figure 1 is a longitudinal cross-sectional view showing a main part of the shoe press mechanism according to the present invention; figure 2 is along figure 1 A cross-sectional view taken along line II-II; FIG. 3 is a perspective view schematically showing the main part of the shoe press mechanism; Figure 4 is a side cross-sectional view showing a state in which the radial position and the rotational phase of the adjustment stay are adjusted, and then the adjustment stay is fixed on the carrier.

[0029] Such as figure 1 with figure 2 As shown, a shoe press mechanism 100 of a paper machine according to the present invention includes a shoe press section 11 and a press roll 13 arranged to face the shoe press section 11 . The shoe press section 11 includes a carrier 15 , a press shoe 19 , a pair of support discs 21 , an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com