Automatic adsorbing device used for array waveguide grating (AWG) and pasting method

An arrayed waveguide grating and adsorption device technology, which is applied to optical waveguides and light guides, etc., can solve the problems of increased clamping and coupling process difficulties, scrapped AWG chips, and high production costs, and can meet production process requirements, facilitate operation, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

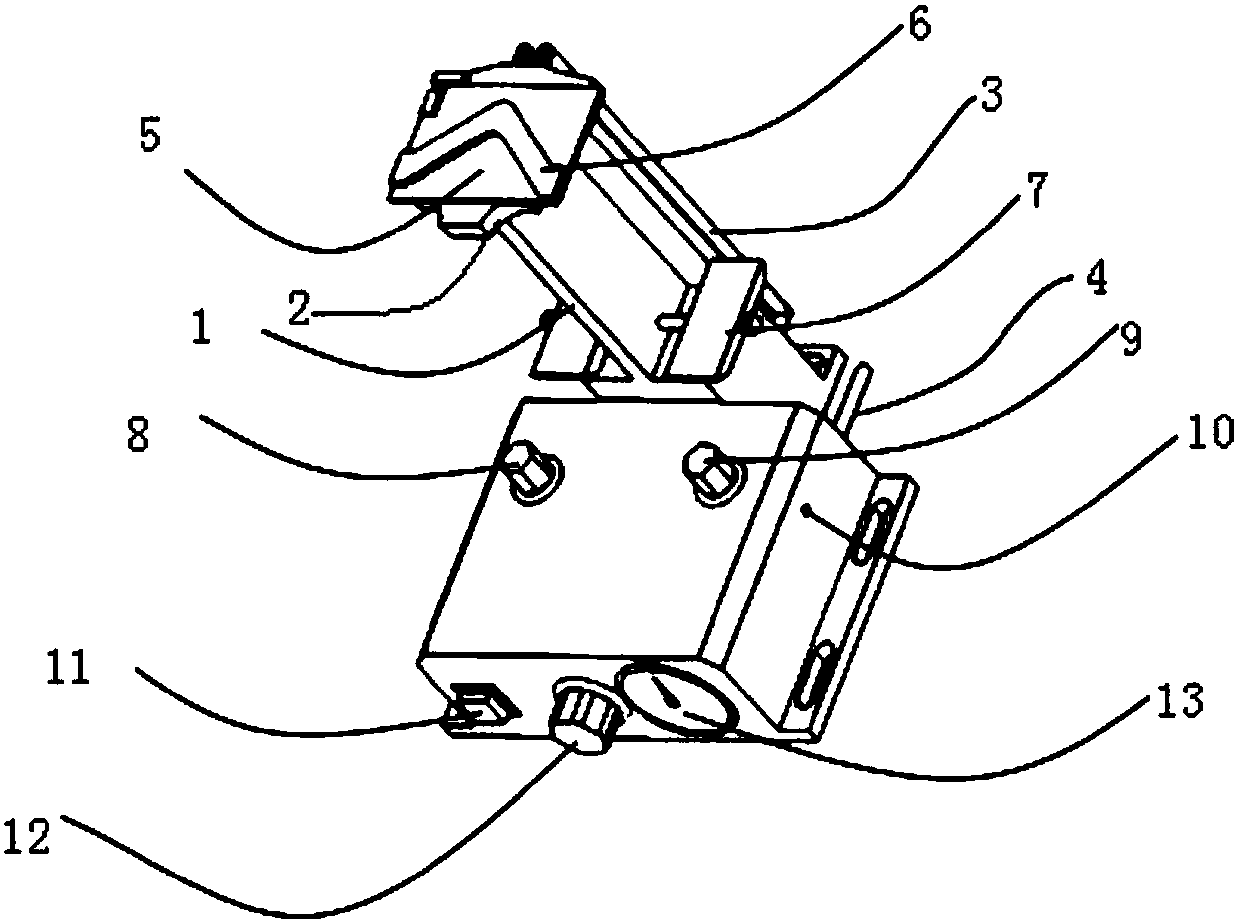

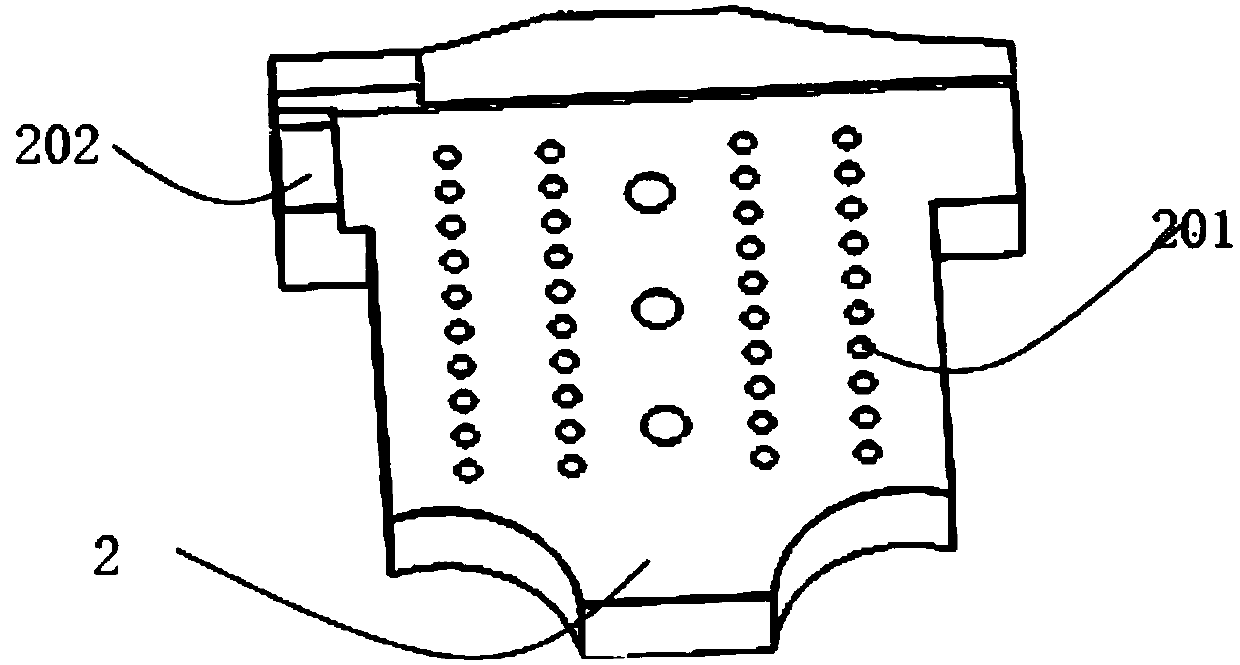

[0036] Such as Figure 1-5 As shown, this embodiment discloses an automatic adsorption device for arrayed waveguide gratings AWG. Its main structure includes: a central support 1, an adsorption platform 2, an air duct 3, and the adsorption platform 2 is arranged on the top of the central support 1. The air guide tube 3 is arranged on one side of the central support 1, one end of the above-mentioned air guide tube 3 is connected to the air pump source 4, and the other end of the above-mentioned air guide tube 3 is connected to the above-mentioned adsorption platform 2, and the above-mentioned adsorption platform 2 is provided with several air suction holes 201, the above-mentioned air guide tube 3 is connected with the above-mentioned suction holes 201, the number of the above-mentioned suction holes 201 can be an even number, and the above-mentioned suction holes are connected in pairs to ensure the uniformity of suction

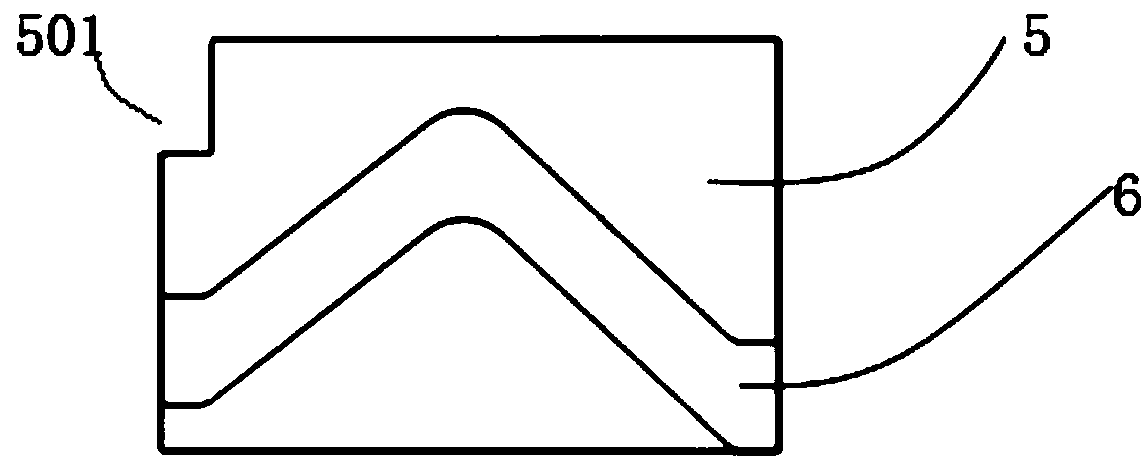

[0037] An optical quartz substrate 5 is detachably fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com