Centrifugal microfluidic serum separation chip and preparation method thereof

A microfluidic chip and serum separation technology, which is applied in clinical diagnosis, health quarantine, and biomedical fields, can solve the problems of micro-full analysis systems, large centrifuge equipment, blood sample loss, etc., and reduce the chance of cross-contamination of blood samples , fast serum separation speed, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

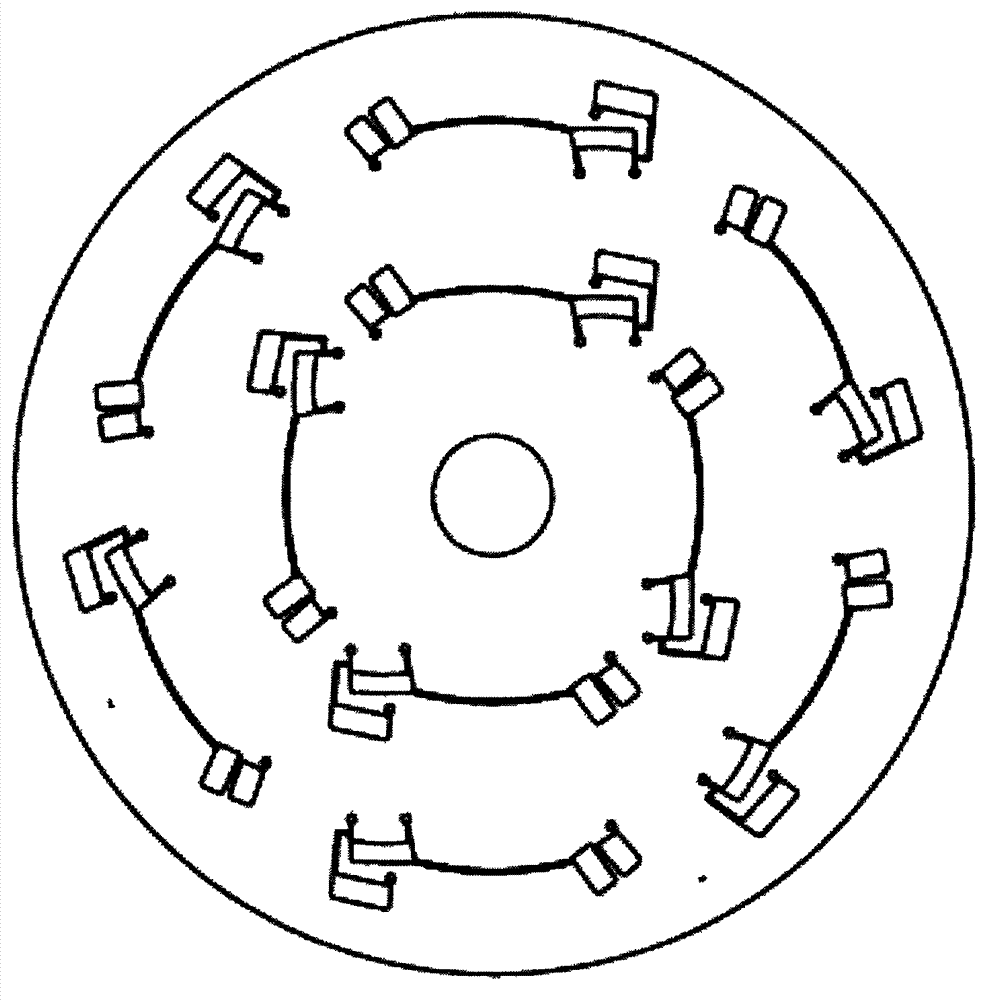

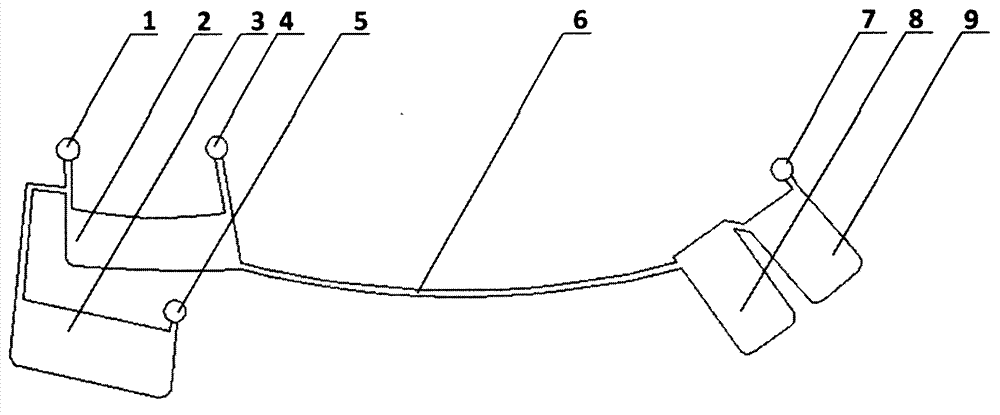

Embodiment 1

[0028] A polymethyl methacrylate (PMMA) chip was prepared by a CNC micromachining system, with a thickness of 3 mm and a diameter of 120 mm, and a central hole with a diameter of 20 mm was punched in the middle. Design the microstructure and microchannel graphics of the centrifugal microfluidic serum separation chip with computer-aided design drawing software (CAD), and then prepare various microchannels, microgrooves, Microwells, micropools, microareas, forming chip microstructures and microchannel systems, including microinjection areas, quantitative areas, waste liquid pools, quartz capillary grooves, split pools, serum areas, vents, and microfluidic flow channels . The PMMA chip and the blank PMMA chip engraved with microstructures and microchannels were washed with ethanol, deionized water, and ethanol in sequence, and then dried naturally. Put a quartz capillary with an outer diameter of 375 μm and an inner diameter of 25 μm into the groove of the quartz capillary, and ...

Embodiment 2

[0030] A polycarbonate (PC) chip was prepared by a CNC micromachining system, with a thickness of 5mm and a diameter of 120mm, and a central hole with a diameter of 30mm was punched in the middle. Use computer-aided design drawing software (CAD) to design centrifugal microfluidic serum separation chip graphics, and then prepare various microchannels, microgrooves, micropores, micropools, micro Area, forming the microstructure and microchannel system of the chip, including a micro-injection area, a quantitative area, a waste liquid pool, a quartz capillary groove, a split pool, a serum area, a vent, and a microfluidic flow channel. Wash the PC chip with the microstructure and microchannel and the blank PC chip sequentially with ethanol, deionized water, and ethanol, and then dry it naturally. Put a quartz capillary with an outer diameter of 375 μm and an inner diameter of 100 μm into the groove of the quartz capillary, fix and seal with epoxy glue. Align and press the PC chip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com