Solid electrolyte composition, solid electrolyte, lithium ion secondary battery, and method for producing lithium ion secondary battery

A solid electrolyte and composition technology, applied in non-aqueous electrolyte battery electrodes, solid electrolytes, secondary batteries, etc., can solve the problems of reduced lithium ion conductivity, high crystallinity, and reduced molecular chain mobility, and achieve lithium ion The effect of improved conductivity and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0078] The first embodiment relates to a unipolar lithium ion secondary battery. The lithium ion secondary battery of the first embodiment is an all solid polymer lithium ion secondary battery.

[0079] (structure)

[0080] figure 1 It is a schematic diagram of the lithium ion secondary battery of the first embodiment. figure 1 A cross section of the lithium ion secondary battery 1002 is shown.

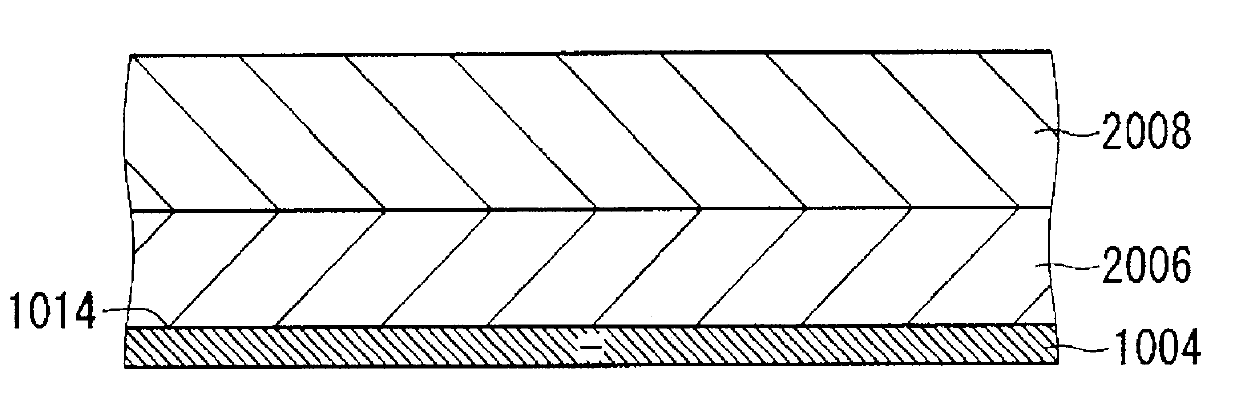

[0081] Such as figure 1 As shown, lithium ion secondary battery 1002 has a structure in which negative electrode current collector 1004 , negative electrode active material layer 1006 , solid electrolyte layer 1008 , positive electrode active material layer 1010 , and positive electrode current collector 1012 are sequentially stacked. The solid electrolyte layer 1008 is sandwiched between the negative electrode active material layer 1006 and the positive electrode active material layer 1010, and the negative electrode active material layer 1006 and the positive electrode active...

no. 2 Embodiment approach

[0159] The second embodiment relates to a method of manufacturing a lithium ion secondary battery suitable for manufacturing the lithium ion secondary battery of the first embodiment.

[0160] (summary)

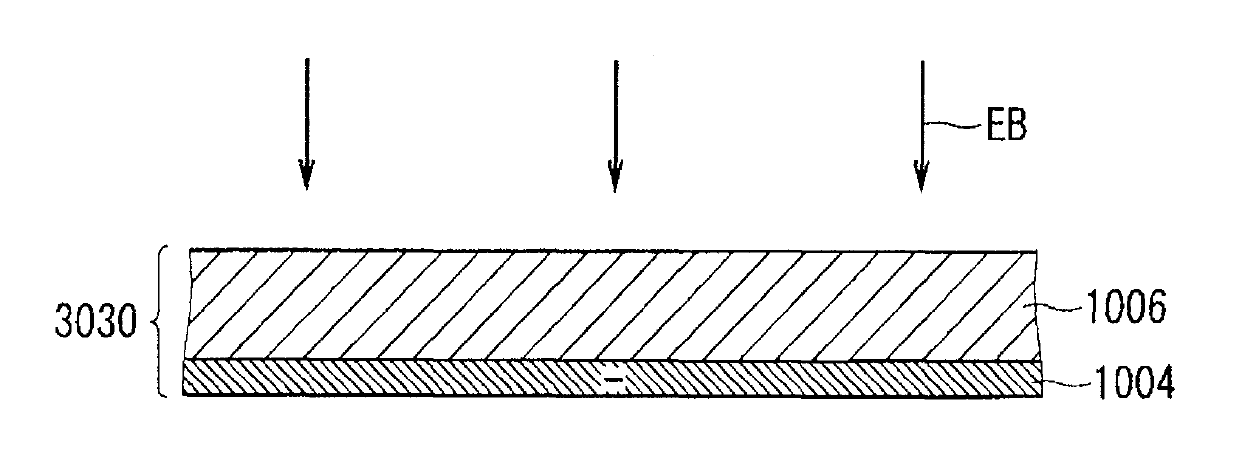

[0161] Figure 6 ~ Figure 10 It is a schematic diagram explaining the manufacturing method of the lithium ion secondary battery of 2nd Embodiment. Figure 6 ~ Figure 10 A cross section of a half-finished lithium ion secondary battery 1002 is shown. In the second embodiment, a negative electrode current collector 1004, a negative electrode active material layer 1006, and a solid electrolyte layer 1008 are stacked. Figure 8 The negative electrode side laminate 2030 shown is formed by laminating the positive electrode active material layer 1010 and the positive electrode current collector 1012. Figure 10 In the positive electrode-side laminate 2032 shown, the negative-electrode-side laminate 2030 and the positive-electrode-side laminate 2032 are bonded together to manufactu...

no. 3 Embodiment approach

[0184] The third embodiment relates to a method of manufacturing a lithium ion secondary battery employed instead of the method of manufacturing a lithium ion secondary battery of the second embodiment.

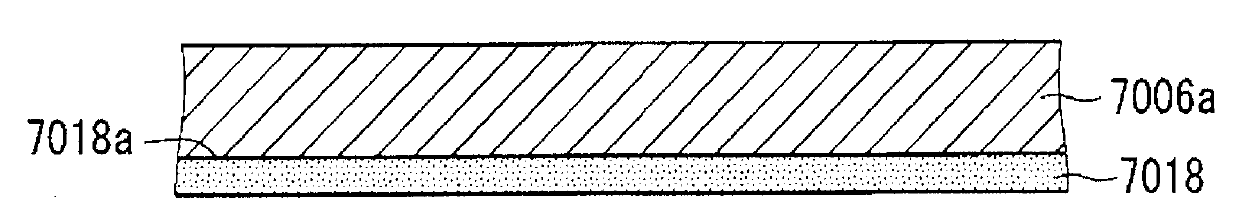

[0185] Figure 11 to Figure 15 It is a schematic diagram explaining the manufacturing method of the lithium ion secondary battery of 3rd Embodiment. Figure 11 to Figure 15 A cross section of a half-finished lithium ion secondary battery 1002 is shown. The second embodiment differs from the third embodiment in that, in the third embodiment, the solid electrolyte layer 1008 is formed on the positive electrode-side laminate 3032 .

[0186] In particular, focusing on the difference between the second embodiment and the third embodiment, a method for manufacturing a lithium ion secondary battery will be described.

[0187] After preparing the precursor mixture, as in Figure 11 As shown, a precursor layer 2006 is formed on the current collecting face 1014 of the negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com