Production method of dye-sensitized TiO2 film based gas sensor

A gas sensor, pigment sensitization technology, applied in instruments, scientific instruments, measuring devices, etc., to achieve the effect of wide detection range, high sensitivity, and enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment uses synthetic pigment sensitization materials and nanocrystalline TiO 2 Combining thin films to make gas sensors, the manufacturing steps are as follows:

[0023] 1. Choose one of silicon wafer, glass wafer, conductive glass wafer and polytetrafluoroethylene wafer as the substrate.

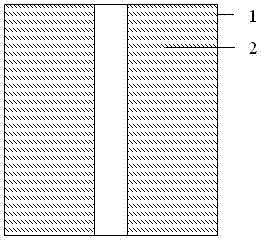

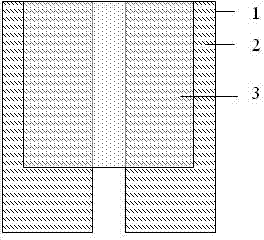

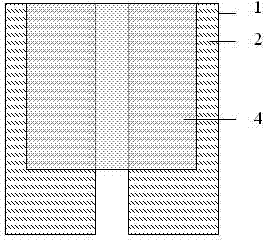

[0024] 2. Make gold or platinum electrodes by screen printing or plasma sputtering methods, such as figure 1 Substrate 1 and electrode 2 are shown.

[0025] 3. Preparation of nanocrystalline TiO by magnetron sputtering 2 Thin film: put the substrate 1 into the base material stage, metal titanium or titanium oxide is used as the target stage, adjust the distance between the titanium target and the substrate stage to 20cm, the rotation speed of the stage is 4rp, and the magnetron The vacuum degree of the sputtering reaction chamber is pumped to at least 10 -3 Pa, the temperature is heated to 20°C, the inert gas flow is 60sccm, the magnetron sputtering power is 80w, and th...

Embodiment 2

[0029] This embodiment is to use natural pigment pigment material and nanocrystalline TiO 2 Combining thin films to make gas sensors, the manufacturing steps are as follows:

[0030] Step 1~step 3 are the same as embodiment 1.

[0031]4. Extraction and preparation of natural color-sensitive materials: Taking purple potato pigment as an example, take 10g of purple potato, wash it, cut it into cubes, put it in a tissue homogenizer, and mash it to get a slurry solution, and measure 10ml with a graduated cylinder Pour the mashed purple potato liquid into a triangular flask, then add 100ml of 1% citric acid, shake well, and place it in a constant temperature water bath at 50°C for 1 hour. After the raw material fades obviously, filter the extract with a qualitative filter paper with a diameter of 15 cm, evaporate and concentrate the extract with a rotary evaporator until the water content is 60%, and obtain the desired concentrated purple sweet potato pigment solution.

[0032] 5...

Embodiment 3

[0034] This embodiment uses synthetic pigment sensitization materials and nanocrystalline TiO 2 Combining thin films to make gas sensors, the manufacturing steps are as follows:

[0035] 1. Choose one of silicon wafer, glass wafer, conductive glass wafer and polytetrafluoroethylene wafer as the substrate.

[0036] 2. Make gold or platinum electrodes by screen printing or plasma sputtering methods, such as figure 1 Substrate 1 and electrode 2 in.

[0037] 3. Preparation of nanocrystalline TiO by magnetron sputtering 2 Thin film: put the substrate into the substrate stage, metal titanium or titanium oxide is used as the target stage, adjust the distance between the titanium target and the substrate stage to 25cm, the rotation speed of the stage is 6rp, magnetron sputtering The vacuum degree of the injection reaction chamber is pumped to at least 10 -3 Pa, the temperature is heated to 100°C, the inert gas flow is 80sccm, the magnetron sputtering power is 100w, and the sputter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com