Dehydroabietylamine-based epoxy resin and preparation method and application thereof

A technology of dehydroabietic amine and epoxy resin, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., to achieve good mechanical properties and corrosion resistance, high heat resistance, good mechanical properties and The effect of thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

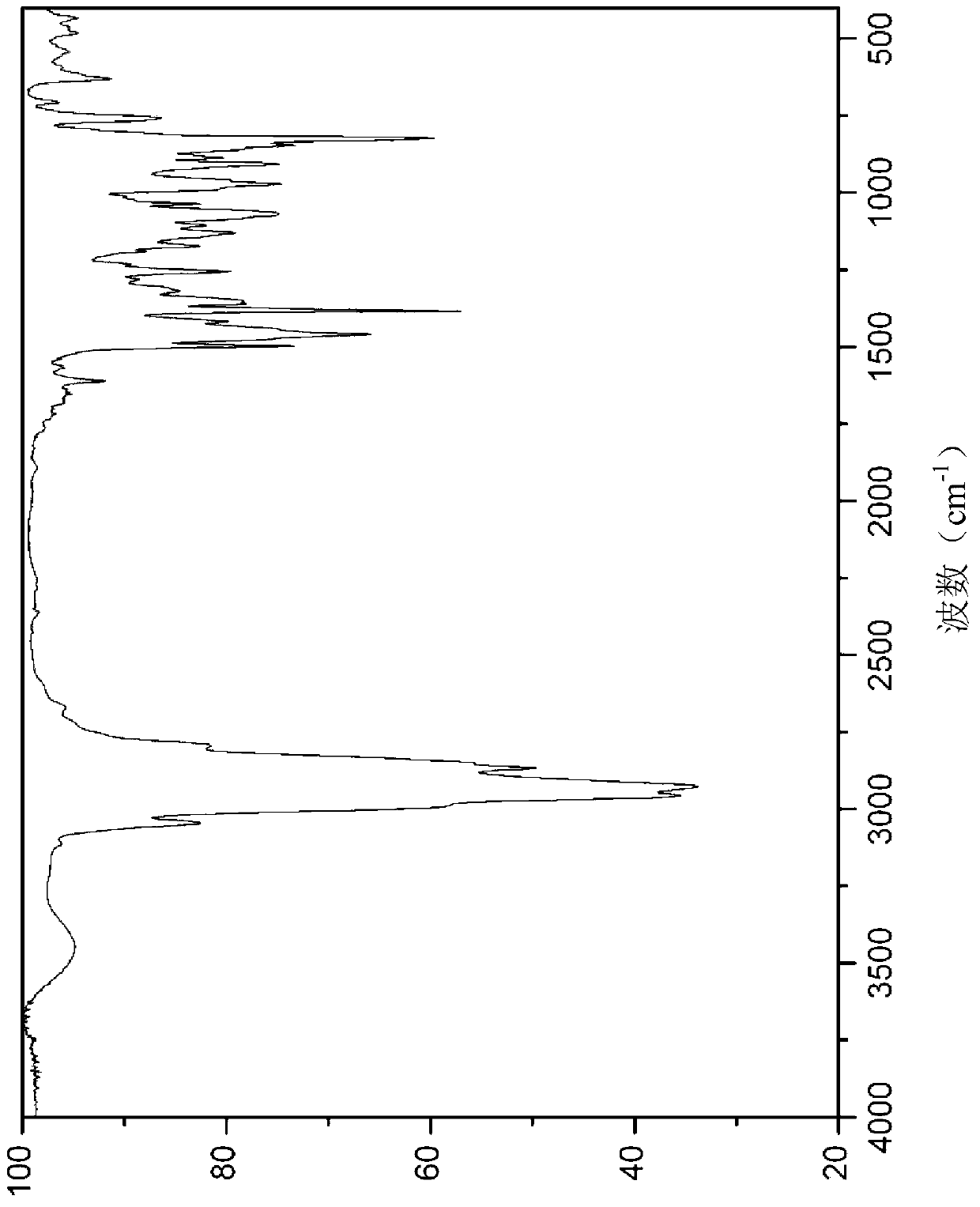

Image

Examples

Embodiment 1

[0039] Mix 100 parts by weight of dehydrorosin amine, 10 parts by weight of water and 500 parts by weight of epichlorohydrin, the temperature is increased to 25°C, 0.1 part by weight of tetramethylammonium chloride is added, and the temperature is reduced to 10°C after 160 hours of reaction , And then add dropwise 100 parts by weight of sodium hydroxide aqueous solution with a content of 30% by weight of sodium hydroxide (ie 30 parts by weight of sodium hydroxide and 70 parts by weight of water), after 1 hour, add 120 parts by weight of ethyl acetate, A reaction system was formed and reacted at 50°C for 5 hours. After the reaction system was cooled to room temperature and 25°C, it was washed with 170 parts by weight of deionized water each time for 4 times, then the solvent was removed with a rotary evaporator, and vacuum dried at 50°C for 12 hours to obtain a light yellow transparent viscous liquid, which is based on The epoxy resin of dehydrorosin amine was 133.3 parts by wei...

Embodiment 2

[0045] Mix 100 parts by weight of dehydrorosinamine, 30 parts by weight of water and 600 parts by weight of epibromide, the temperature is increased to 40°C, 0.5 parts by weight of octadecyltrimethylammonium bromide is added, and after reaction for 120h Cool down to 30°C, then add 120 parts by weight of potassium hydroxide aqueous solution (ie 42 parts by weight of potassium hydroxide and 78 parts by weight of water) with a potassium hydroxide content of 35% by weight, and add chloroform after 1 hour. 200 parts by weight to form a reaction system, and continue to react at 30°C for 3 hours. After the reaction system is lowered to room temperature and 25°C, it is washed with 150 parts by weight of deionized water each time for a total of 3 times, then the solvent is removed by a rotary evaporator, and vacuum dried at 50°C for 12 hours to obtain an epoxy resin based on dehydrorosinamine The resin was 136.8 parts by weight, and the yield based on dehydroabietic amine was 97.5%.

[0...

Embodiment 3

[0049] Mix 100 parts by weight of dehydrorosinamine, 20 parts by weight of water and 400 parts by weight of epichlorohydrin, the temperature is increased to 90°C, 1.2 parts by weight of hexamethylenetetraammonium are added, and the temperature is lowered after reacting at 90°C for 72 hours To 30°C, then add dropwise 180 parts by weight of barium hydroxide aqueous solution containing 35% by weight of barium hydroxide (that is, 63 parts by weight of barium hydroxide and 117 parts by weight of water), after 1 hour, add 60 parts by weight of ether , Forming a reaction system, react at 20°C for 4h. After the reaction system is lowered to room temperature and 25°C, it is washed with 200 parts by weight of deionized water each time for a total of 4 times, then the solvent is removed with a rotary evaporator, and vacuum dried at 50°C for 12 hours to obtain a dehydrorosinamine-based epoxy The resin was 136.8 parts by weight, and the yield based on dehydroabietic amine was 98.2%.

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com