Preparation method of manganous-manganic oxide and manganous-manganic oxide

A technology of trimanganese tetraoxide and manganese dioxide, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of losing application value and the particle size distribution of manganese dioxide tail powder not meeting the requirements, so as to improve the appearance and improve the Efficiency, the effect of increasing the packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

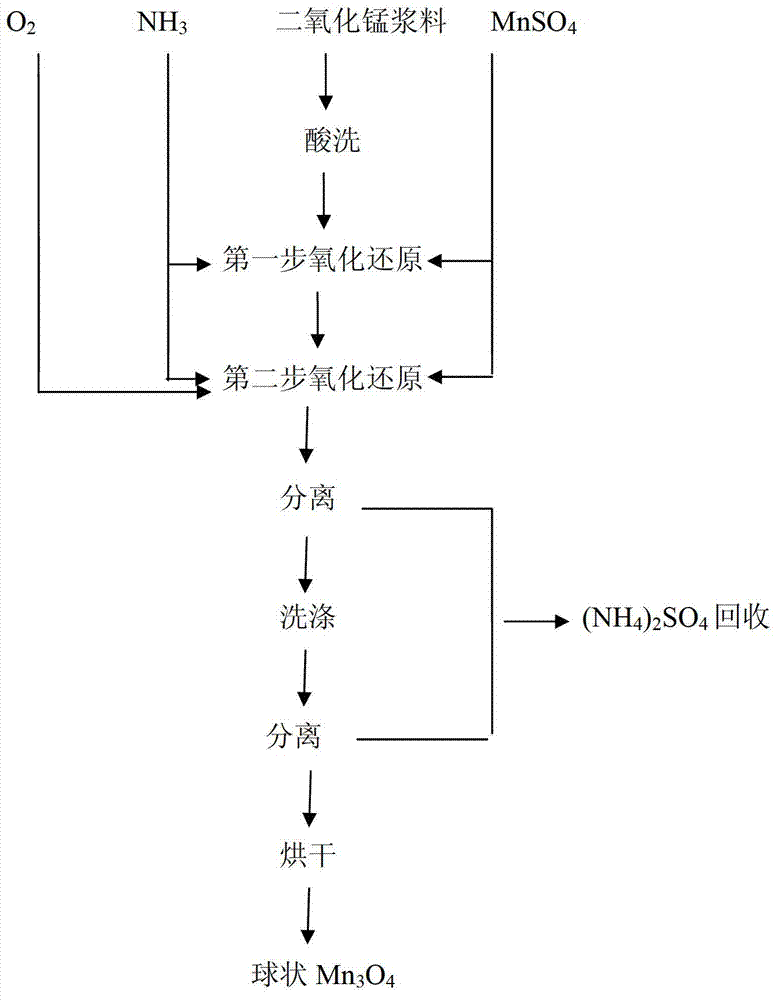

Method used

Image

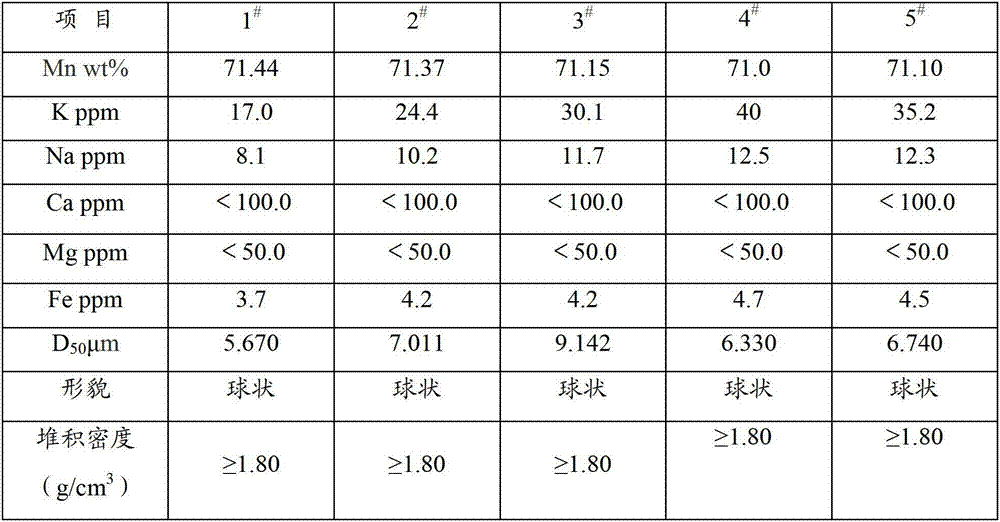

Examples

Embodiment 1

[0075] 1) pickling

[0076] Add deionized water to 200 kg of electrolytic manganese dioxide (EMD) tail powder according to the material-to-water ratio of 1:5 to make manganese dioxide slurry. Among them, the MnO of electrolytic manganese dioxide (EMD) tail powder 2 The content is about 91wt%, D 50 The particle size is 1.0 μm, and the Fe content is 100 ppm. Adjust the pH value of the slurry to 2.3 with sulfuric acid, stir the slurry at 65°C for 2 hours, press filter and separate, and the obtained solid phase (manganese dioxide) is washed before proceeding to the next step.

[0077] 2) The first step redox

[0078] Press MnO 2 :MnSO 4 = 1:1.5 molar ratio, that is, the manganese dioxide after pickling is added to 3120L of manganese sulfate solution with a concentration of 150g / L, and the container is replaced with nitrogen, and the solution is heated to 58°C under stirring; then, NH 3 Maintain the pH value of the solution at 7.7, and keep stirring for 1 hour after the pH va...

Embodiment 2

[0083] 1) pickling

[0084] Add deionized water to 200 kg of electrolytic manganese dioxide (EMD) tail powder according to the material-to-water ratio of 1:5 to make manganese dioxide slurry. Among them, the MnO of electrolytic manganese dioxide (EMD) tail powder 2 The content is about 91wt%, D 50 The particle size is 0.5 micron, and the mass content of Fe is 80ppm. Adjust the pH value of the slurry to 2.2 with sulfuric acid, stir the slurry at 62°C for 2 hours, press filter and separate, and the obtained solid phase (manganese dioxide) is washed and then enters the next step.

[0085] 2) The first step redox

[0086] Press MnO 2 :MnSO 4 =1:1.5 molar ratio, add manganese dioxide after pickling to 3120L of manganese sulfate solution with a concentration of 150g / L, replace with nitrogen and seal the container, stir the solution to heat up to 56°C; then, feed NH 3 The pH value of the solution was maintained at 7.6, and after the pH value of the solution was stabilized, the ...

Embodiment 3

[0090] 1) pickling

[0091] Add deionized water to 200 kg of electrolytic manganese dioxide (EMD) tail powder according to the material-to-water ratio of 1:5 to make manganese dioxide slurry. Among them, the MnO of electrolytic manganese dioxide (EMD) tail powder 2 The content is about 91wt%, D 50 The particle size is 1.8 microns, and the mass content of Fe is 150 ppm. Adjust the pH value of the slurry to 2.4 with sulfuric acid, stir the slurry at 68° C. for 2 hours, press filter and separate, and the obtained solid phase (manganese dioxide) is washed and then enters the next step.

[0092] 2) The first step redox

[0093] Press MnO 2 :MnSO 4 =1:1.5 molar ratio, add manganese dioxide after pickling to 2790L of manganese sulfate solution with a concentration of 170g / L, replace with nitrogen and seal the container, stir the solution to heat up to 58°C; then, pass in NH 3 The pH value of the solution was maintained at 7.8, and after the pH value of the solution was stabilized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com