Spiral electrostatic dust collecting plant

An electrostatic dust collection and spiral technology, applied in electrode conveying device, electrostatic separation, electrode structure and other directions, can solve the problems of limited application scope, low processing efficiency, large size and volume, etc., and achieves good electrostatic adsorption effect, easy processing, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

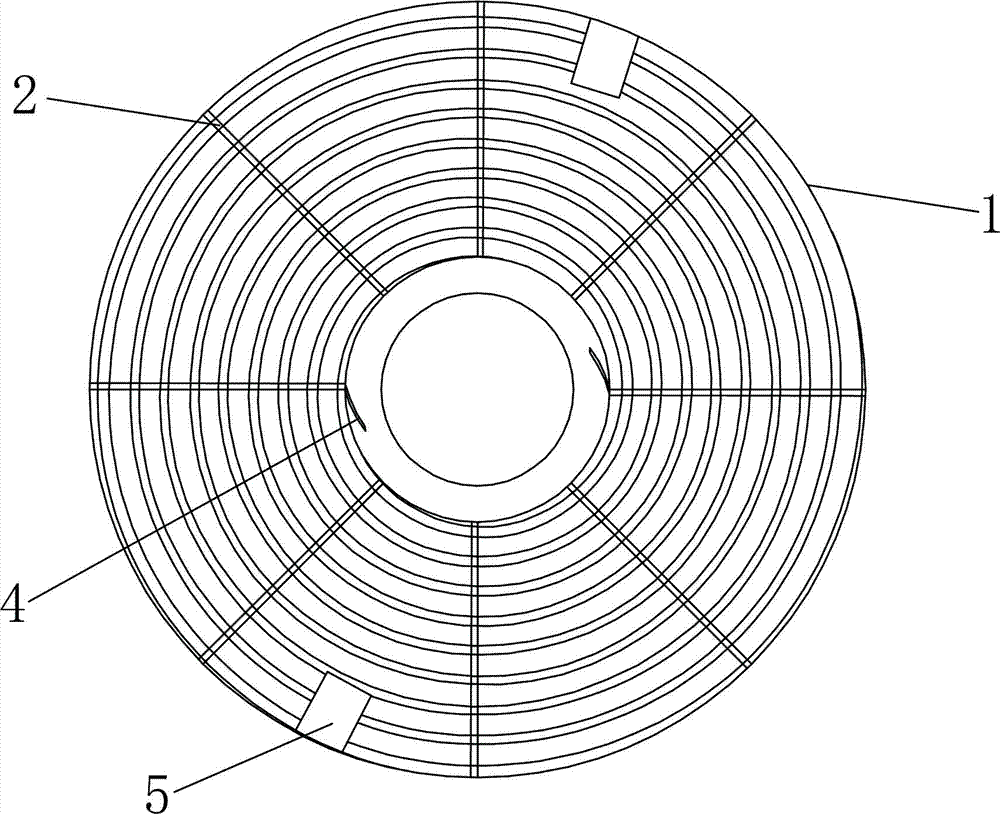

Embodiment 1

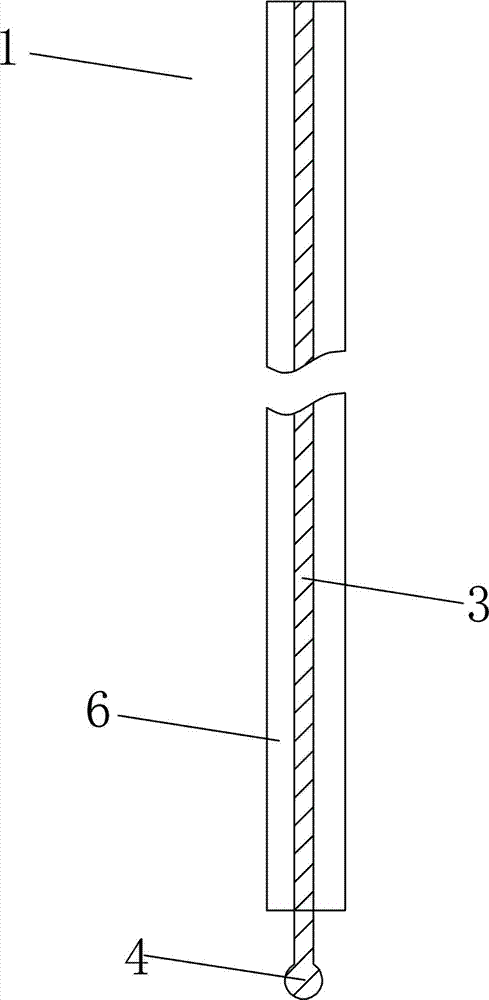

[0038] Embodiment 1: refer to Image 6 . The dust collection belt 1 is curled in a spiral ring shape, and the distance between the dust collection belts is small, which can generate the best electric field, and can achieve the same dust collection effect at half the size of the traditional electrostatic precipitator. In addition, it is convenient for production and processing, and has a disc shape It is also conducive to standardized installation. The insulating tape 6 is made of kraft paper insulating tape, which is light in weight, low in cost, easy to process and has a good insulating effect. The thickness of the insulating tape 6 of kraft paper is 0.5mm. In order to achieve a good dust collection effect , and according to the design size of the installation equipment, the distance between the two dust collection belts 1 is set to 1.2mm. The dust collection belt 1 is an insulating belt 6 provided with a continuous conductive strip 3, and the conductive strip 3 is conductive...

Embodiment 2

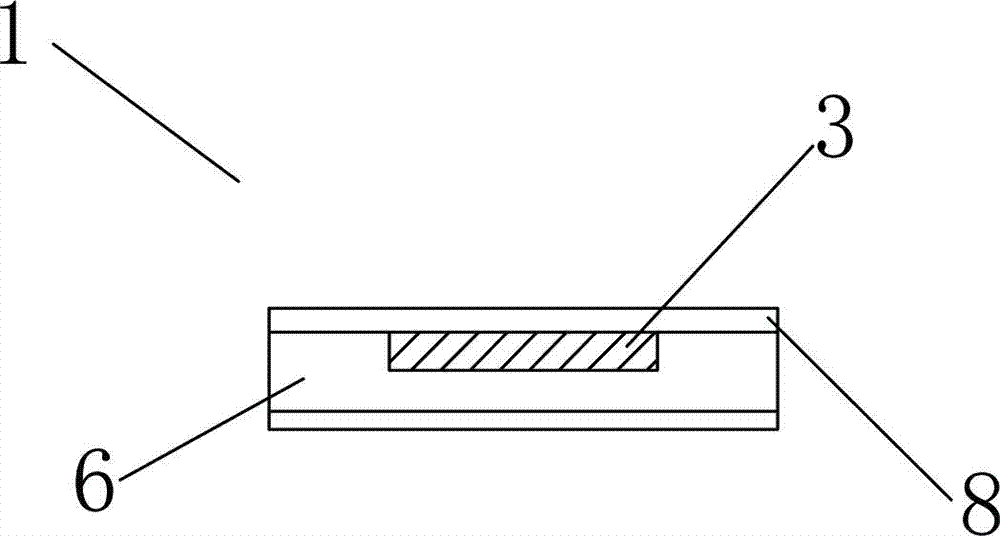

[0039] Embodiment 2: refer to Figure 7 . In this embodiment, the dust collection belt 1 is designed as a square spiral according to the equipment structure requirements, and the distance between the two dust collection belts 1 is 0.8mm; the dust collection belt 1 is made of conductive material, the material is a metal copper strip, and the thickness is 0.5mm, resistivity 1.8×10 -8 Ω·m.

[0040]In order to prevent the voltage from breaking down the air to generate ozone, an insulating layer 8 is provided on the surface of the dust collecting belt 1. In this embodiment, the insulating layer 8 is an insulating coating. The electric connection 4 is arranged on the outer side of the spiral ring in parallel.

[0041] In order to facilitate the fixing of the electrostatic precipitator, the support part 2 is made of hot-melt glue, and is arranged at the four corners of the square ring.

[0042] The above two embodiments are electrostatic dust collection devices applied to air pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com