Method for preparing thalli/ bentonite organic and inorganic composite adsorbent

An inorganic composite, bentonite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation process, difficult removal of heavy metals, poor decolorization effect, etc. The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with examples.

[0014] Add 10g of Aspergillus niger mycelium powder and 250g of bentonite into a 500mL large beaker and mix evenly, then add 312mL of industrial hydrochloric acid with a mass fraction of 3%, or 312mL of 3% sulfuric acid, stir while adding, continue to stir and mix for 15min, and let stand After activating for 15-25 minutes, place it in a microwave oven at 480W to heat, modify and dry it, take it out and cool it, and grind it into powder, which is the prepared mycelium / bentonite organic-inorganic composite water treatment agent product. Bentonite is the natural bentonite in Heishan Chengdong, Liaoning.

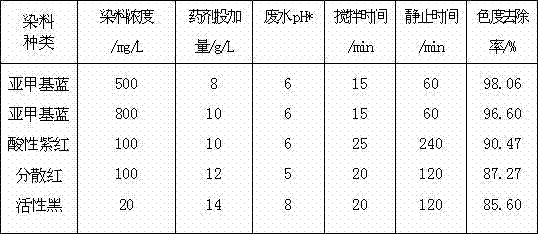

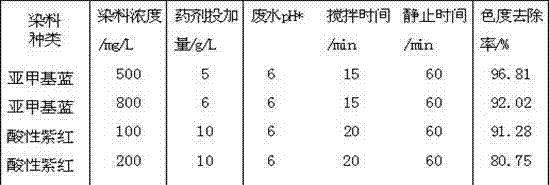

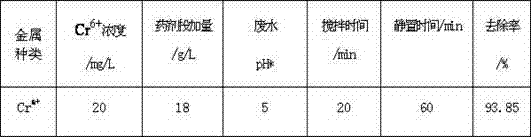

[0015] Use this product to treat various concentrations of single dye simulated wastewater and Cr commonly used in printing and dyeing factories 6+ The simulated wastewater has received a better treatment effect. The processing results are shown in Table 1 and Tables 2 and 3.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com