Hollow microsphere and its preparation method

A microsphere and hollow technology, applied in the field of hollow microspheres and their preparation, can solve the problems of cumbersome process, compound hollow microspheres have not yet been synthesized, and difficulty in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

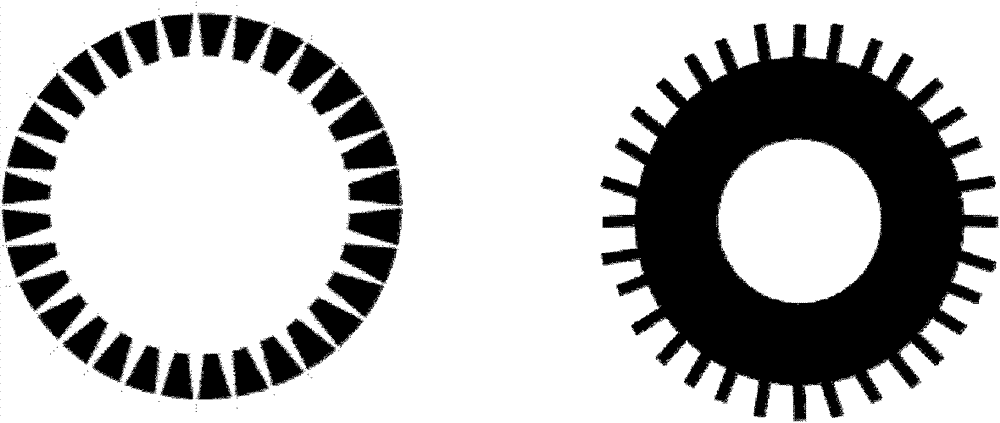

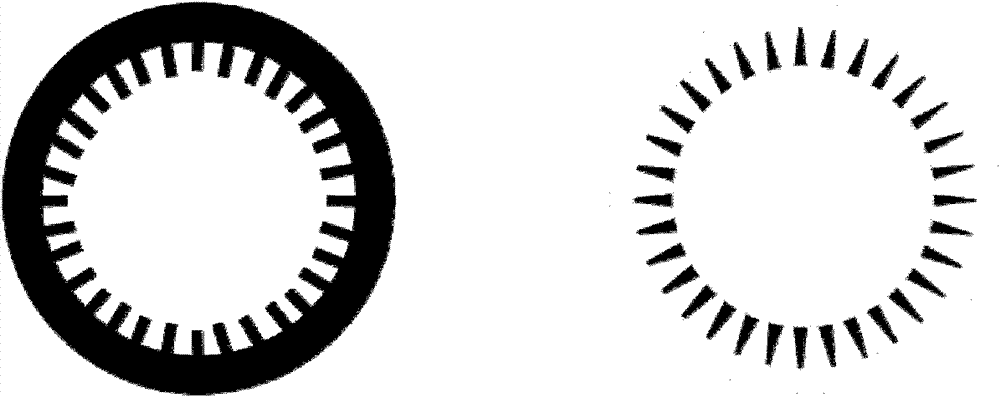

Image

Examples

Embodiment 1

[0049] Embodiment 1, utilizing method one to prepare hollow microspheres

[0050] 1) 9.0g inorganic precursor TEOS (tetraethyl orthosilicate Si(OCH 2 CH 3 ) 4 ) and 3.0 mL of hydrochloric acid with a concentration of 2 mol / L were dissolved in 87 g of acetone, and after reflux at 60°C for 4 hours, 1 g of ethyl 2-cyanoacrylate was added and mixed evenly to obtain a mixed solution; the obtained mixed solution was pumped into The air-flow spray drying equipment adopts the co-current drying method for drying. The atomization device of the spray dryer adopts a two-flow nozzle, and the feeding speed of the mixed liquid is 15mL / min; the gas flow rate of the nozzle is controlled by the pressure of the compressed air, and the gas flow rate It is 30L / h; control the feed temperature (i.e. the air inlet temperature) to 25°C, and the outlet air is separated and emptied by a primary vortex to obtain hollow microspheres a;

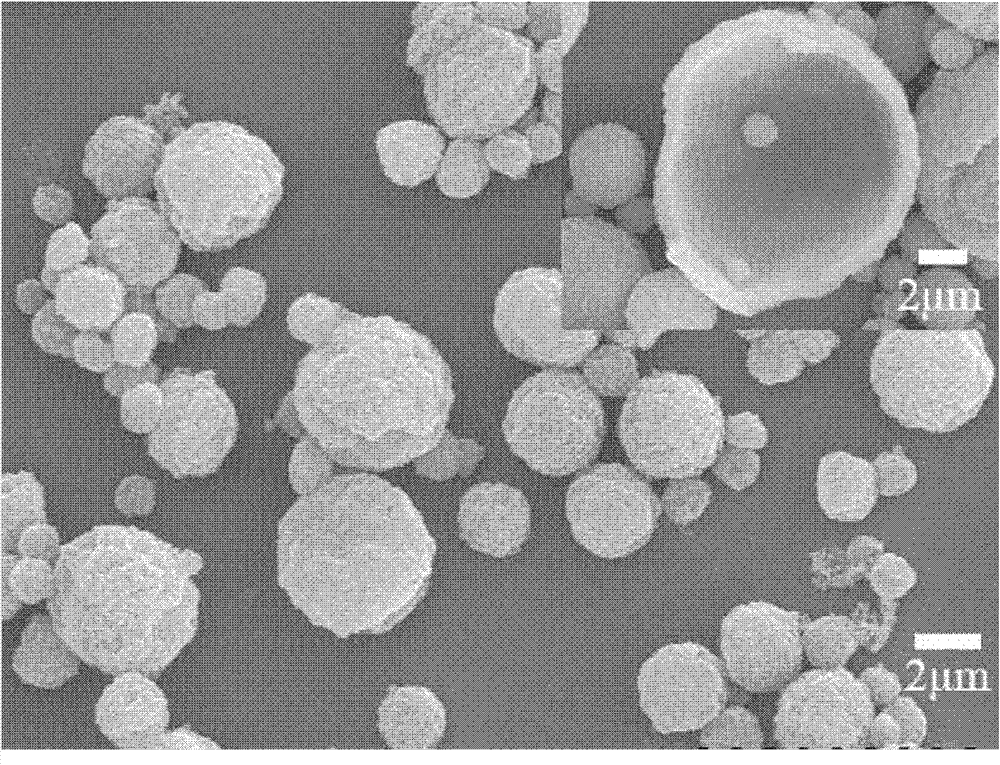

[0051] The SEM photograph of this hollow microsphere a is as fi...

Embodiment 2

[0054] According to the same experimental conditions and step 1) as in Example 1, only step 2) the acetone used in the soaking step is replaced with hydrofluoric acid with a mass percentage concentration of 10%, and the hollow microspheres are removed after soaking with this hydrofluoric acid Silica in a, the material that obtains the wall that the present invention provides is the hollow microsphere of polyethyl 2-cyanoacrylate, and its SEM picture is as follows Figure 4 shown. Depend on Figure 4 It can be seen that the particle size of the microspheres is 500nm-50μm. After the treatment with hydrofluoric acid, the microspheres adhere to each other, and a small amount of microspheres collapse or even rupture.

Embodiment 3

[0056] According to the same experimental conditions and step 1) as in Example 1, only after step 1) and before step 2), the obtained hollow microsphere a was heat-treated at 350° C. for 24 hours to obtain hollow microsphere b. After the same step 2) as in Example 1, the material forming the wall provided by the present invention is a hollow microsphere of silicon dioxide. SEM observation shows that the particle diameter of the microsphere is 500nm-50 μm, and the wall is 100nm- 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com