Process for coloring aluminum sections with pure black pigment

An aluminum profile, black material technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of difficult deposition to the bottom, unstable color, etc., achieve uniform color and easy adjustment, and increase electrophoresis. Ability, Analysis, and Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method of this embodiment includes:

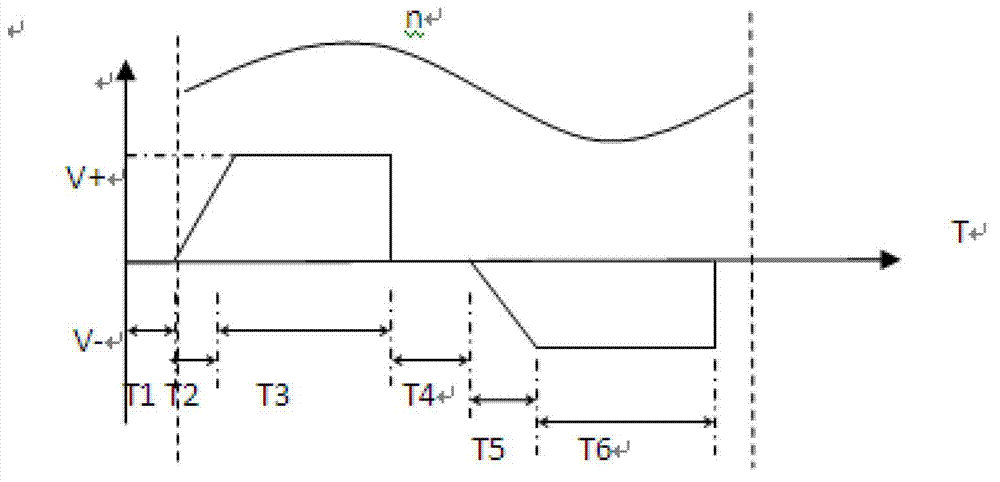

[0032] Put the oxidized aluminum profile into the anode of the coloring tank for electrolysis, and then put the oxidized aluminum profile in the cathode for DC coloring treatment to make Ni 2+ Into the pores of the oxide film and deposited to the bottom, the direct current coloring treatment includes the following steps in sequence:

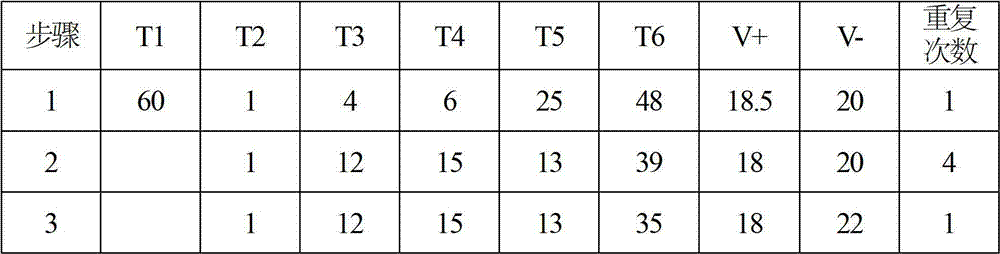

[0033] 1) Soak the oxidized aluminum profile in the colorant in the coloring tank for 60 seconds, and then apply positive voltage to make the positive voltage rise from 0 to 18.5v within 4 seconds for 6 seconds, then stop energizing for 1 second, and then turn on again Negative voltage, so that the negative voltage rises from 0 to 20v within 25 seconds and lasts for 48 seconds;

[0034] 2) Turn on the positive voltage, so that the positive voltage rises to 18v within 12 seconds, and last for 15 seconds, then stop the power supply for 1 second, and then turn on the negative voltage, so that the neg...

Embodiment 2

[0042] The method of this embodiment includes:

[0043] Put the oxidized aluminum profile into the anode of the coloring tank for electrolysis, and then put the oxidized aluminum profile in the cathode for DC coloring treatment to make Ni 2+ Into the pores of the oxide film and deposited to the bottom, the direct current coloring treatment includes the following steps in sequence:

[0044] 1) Soak the oxidized aluminum profile in the colorant in the coloring tank for 61 seconds, and then apply positive voltage to make the positive voltage rise from 0 to 18.5v within 4 seconds for 7 seconds, then stop energizing for 1 second, and then turn on again Negative voltage, so that the negative voltage rises from 0 to 20v within 23 seconds and lasts for 50 seconds;

[0045] 2) Turn on the positive voltage, so that the positive voltage rises to 18v within 12 seconds, and last for 15 seconds, then stop the power supply for 1 second, and then turn on the negative voltage, so that the neg...

Embodiment 3

[0053] The method of this embodiment includes:

[0054] Put the oxidized aluminum profile into the anode of the coloring tank for electrolysis, and then put the oxidized aluminum profile in the cathode for DC coloring treatment to make Ni 2+ Into the pores of the oxide film and deposited to the bottom, the direct current coloring treatment includes the following steps in sequence:

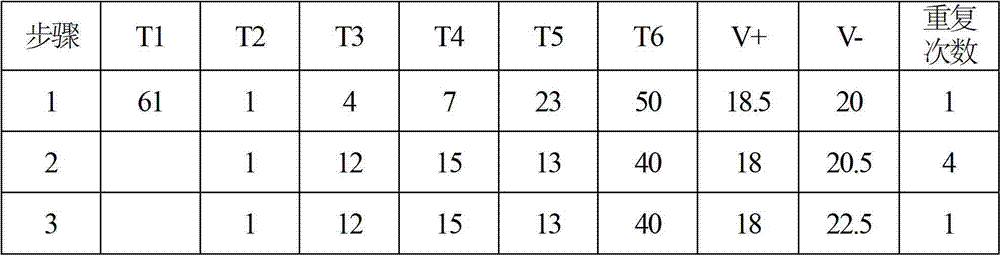

[0055] 1) Soak the oxidized aluminum profile in the coloring agent in the coloring tank for 62 seconds, and then apply positive voltage to make the positive voltage rise from 0 to 18.5v within 4 seconds for 8 seconds, then stop energizing for 1 second, and then turn on again Negative voltage, so that the negative voltage rises from 0 to 20v within 25 seconds and lasts for 48 seconds;

[0056] 2) Turn on the positive voltage, so that the positive voltage rises to 18v within 12 seconds, and last for 15 seconds, then stop the power supply for 1 second, and then turn on the negative voltage, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com