A composite energy-saving cathode for electrolytic manganese

An electrolytic manganese and cathode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of corrosion of stainless steel bolts, increase of contact resistance, impact on output and current efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

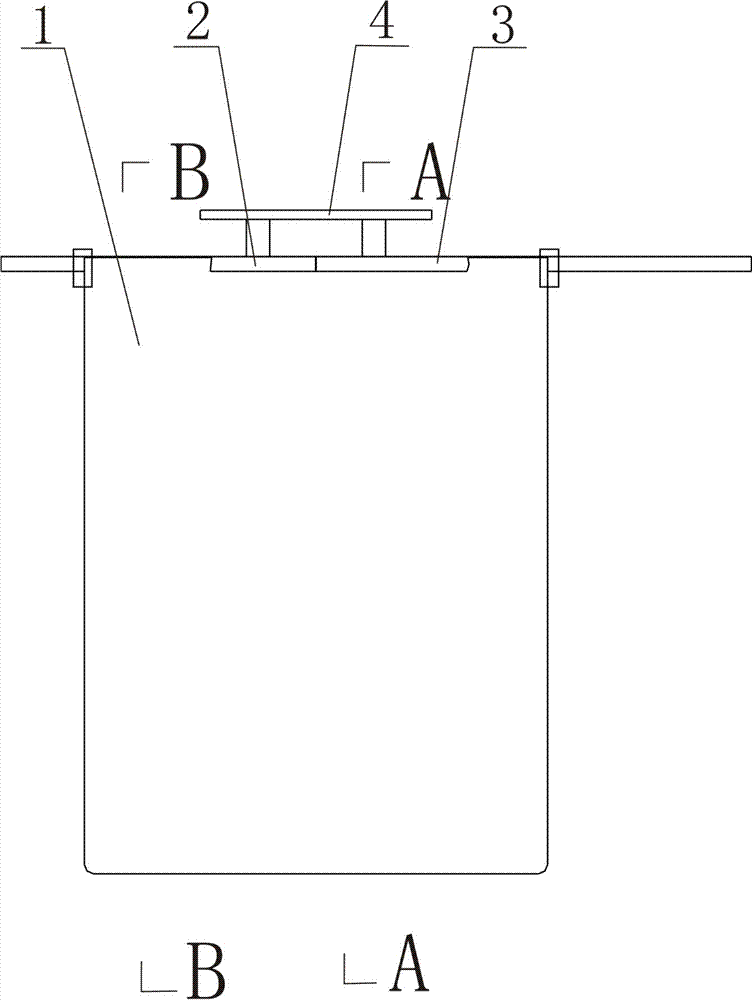

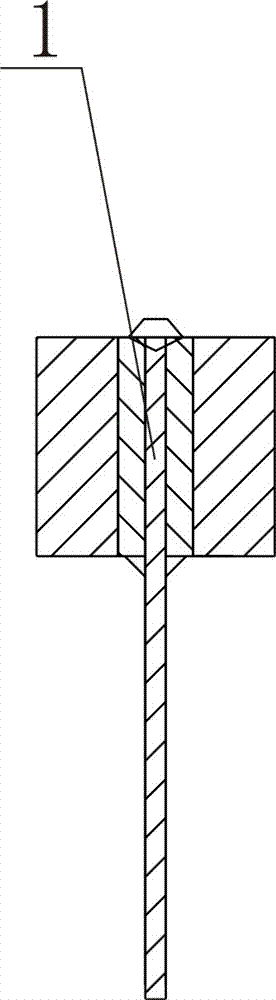

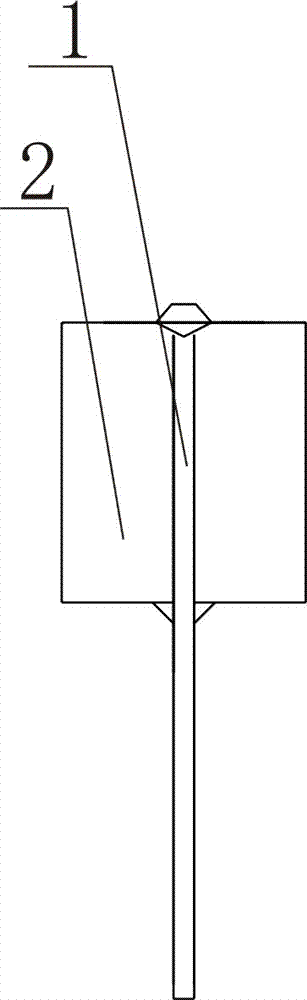

[0015] Such as Figure 1~3 As shown, a composite energy-saving cathode for electrolytic manganese, including a stainless steel plate 1, a handle, and the handle is connected to the stainless steel plate 1. The handle is formed by connecting a stainless steel bar part 2 and a composite material part 3 . The stainless steel plate 1, the stainless steel bar part 2 and the composite material part 3 are welded by stainless steel. A handle 4 is fixedly connected on the handle, and the handle 4 is a stainless steel handle welded on the handle.

[0016] The composite material part 3 is composed of stainless steel strips and copper strips through explosive welding. Divided into: upper and lower layers of copper bars, with two layers of stainless steel bars in the middle, the copper bars and stainless steel bars are bonded by explosive welding.

[0017] The ends of the stainless steel strip part 2 and the composite material part 3 are respectively provided with stepped surfaces, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com