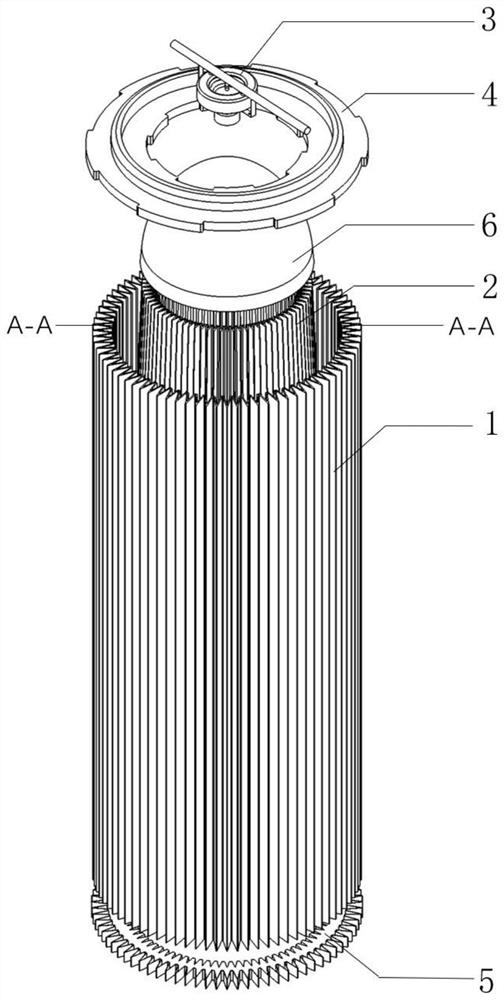

Efficient filtering and deashing device with inner cone double-layer filter cartridge

A high-efficiency filtration and ash cleaning device technology, applied in safety devices, dispersed particle filtration, transportation and packaging, etc., can solve the problems of not effectively utilizing the bottom and inner space of the filter cartridge, reducing the service life of the filter element, and reducing the filter area, etc. The effect of improving the filtering and dust removal effect, prolonging the service life and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

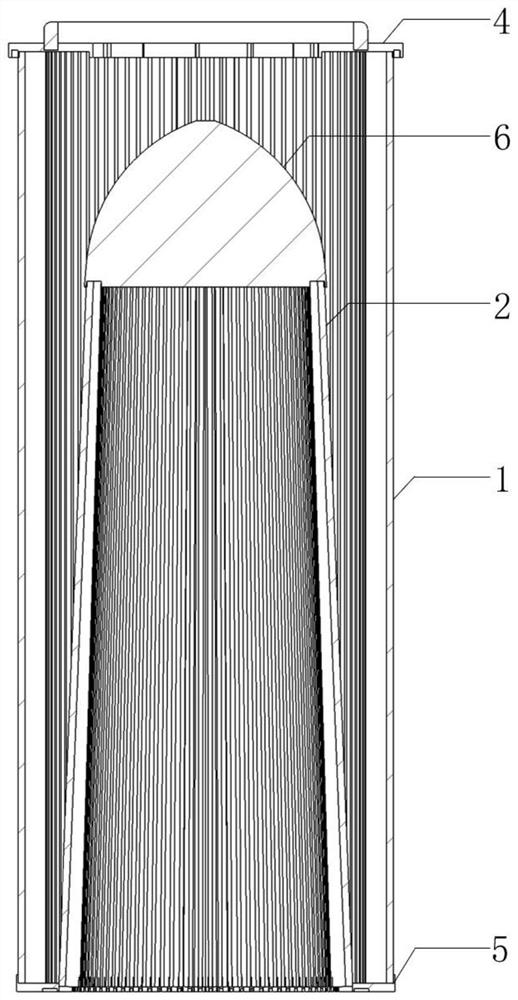

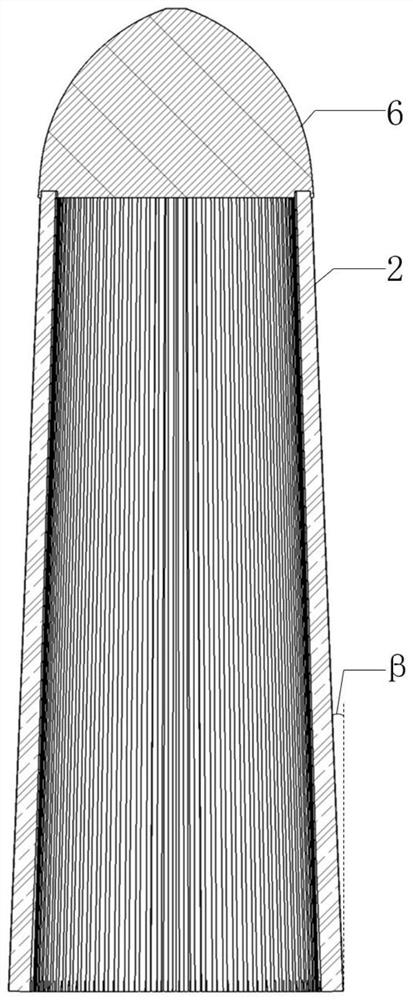

[0064] The height of the outer filter cartridge provided in this example is 66cm, the outer diameter is 39.2cm, the inner diameter is 28cm, the number of pleats is 40, and the measured area of the filter surface is 13200cm 2 ; The length of the inner cone filter cartridge is 56cm, the inner cone angle is 10°, and the measured filter surface area is 9080cm 2 , the total filter surface area is 22280cm 2 ;Comparing the triangular pleated filter cartridges with the same height, outer diameter, inner diameter and number of pleats, the measured filter surface area is 10560cm 2 . Therefore, under the same conditions, the filter surface area of the filter cartridge provided by the present invention is 2.1 times the filter surface area of the ordinary triangular pleated filter cartridge.

[0065] Under the condition of capturing the same amount of dust, the thickness of the dust captured by the present invention is 2mm. After the dust is accumulated, the volume of the pleated f...

Embodiment 2

[0068] In the cleaning process, in order to pursue better cleaning effect and cleaning uniformity, the calculation formula of the distance s from the bottom of the double-slit blowing pipe to the top of the oblate sphere of the present invention is as follows:

[0069] 0.5α=tan -1 [(D in -d) / 2]

[0070] α=0.0712d 2 +0.2082d+15.568

[0071] s=[(D in -d) / 2] / tan[(0.0712d 2 +0.2082d+15.568) / 2]

[0072] where:

[0073] α injection angle (the angle between the bottom of the injection pipe body and the outer filter cartridge);

[0074] D in is the diameter of the outer filter;

[0075] d is the diameter of the injection pipe body;

[0076] s is the blowing distance (the distance between the bottom of the diversion nozzle and the top of the outer filter cartridge 1)

[0077] The diameter D of the outer filter provided in this embodiment inis 280mm, and the diameter d of the blowing pipe body is 22mm, then it can be obtained: α=0.0712×22 2 +0.0282×22+15.568=54.6°

[0078]...

Embodiment 3

[0081] The diameter of the air flow connecting pipe in the double-slit blowing pipe provided in this embodiment is 5 mm, the diameter of the diversion connecting pipe is 6 mm, and the distance between the inner seam and the outer seam between the blowing pipe cover and the blowing pipe body is 0.8 mm. The distance between the tapered part of the guide connection pipe and the lower part of the connection pipe is 0.5 mm. Under the condition that the airflow pressure in the high-pressure airflow pipe is 0.5MPa and the filtration wind speed is 4m / min, when the double-slit blowing pipe is used for dust cleaning, the total dust emission concentration of the filter cartridge is 1.49mg / m2 3 , the peak value of dust concentration during pulse injection is 19.20mg / m 3 , the pressure difference is reduced by 98Pa after pulse injection; when using ordinary nozzles for dust cleaning, the total dust emission concentration of the filter cartridge is 3.40mg / m 3 , the peak dust concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com