Technology and device thereof adopting bottom blowing molten bath for antimony reduction and smelting

A technology for melting and smelting antimony in a molten pool, applied in the field of antimony smelting, can solve the problems that sodium-alkali slag cannot be used as waste slag, the service life of refractory bricks is short, and the cost of antimony smelting is increased, so as to prolong the service life of masonry, prolong the service life, improve the Effect of processing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

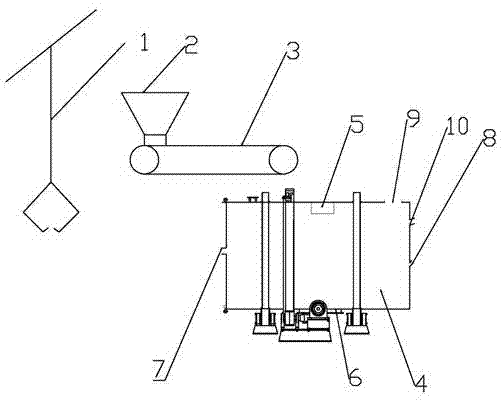

[0036] Such as figure 1 , figure 2 As shown, high-antimony slag, high-antimony soot after granulation, iron ore, gravel, and coke are driven by grab buckets according to the weight ratio of 100:0~100:2~15:2~15:5~15 1. Mix the ingredients, and the mixed materials are transported to the silo 2 with a grab bucket. The materials in the silo are continuously quantified by nuclear belt scales or electronic belt scales. The antimony smelting furnace 4 melts and undergoes reduction and slagging reactions; the molten pool smelting antimony smelting furnace maintains negative pressure, the liquid level maintains a molten pool of 600-1000mm, and the temperature maintains 900-1200°C. By adjusting the molten pool, the antimony smelting furnace The gas flow in the spray gun 6 controls the furnace temperature, so that the materials entering the furnace are melted in a short time, and the reduction and slagging reactions occur; the strong reducing atmosphere in the furnace is controlled by ...

Embodiment 2

[0038] Such as figure 1 , figure 2 As shown, antimony oxide ore, iron ore, quartz, gravel, and coke are mixed according to the ratio of 100:0~100:2~15:2~15:5~15 by weight, and the mixing The final material is transported to the silo 2 with a grab bucket, and the material in the silo is continuously quantified by the nuclear belt scale or the electronic belt scale 3, and enters the molten pool smelting antimony smelting furnace 4 to be melted and Reduction and slagging reactions occur; negative pressure is maintained in the molten pool smelting antimony smelting furnace, the liquid level maintains a molten pool of 600-1000mm, and the temperature maintains 900-1200°C. By adjusting the gas flow in the spray gun 6 of the molten pool smelting antimony Control the furnace temperature so that the materials entering the furnace melt in a short time, and undergo reduction and slagging reactions; the strong reducing atmosphere in the furnace is controlled by the amount of coke in the ...

Embodiment 3

[0040] Such as figure 1 , figure 2 As shown, antimony oxide powder, iron ore, quartz, gravel, and coke are mixed according to the ratio of 100:0~100:2~15:2~15:5~15 by weight, and the mixing The final material is transported to the silo 2 with a grab bucket, and the material in the silo is continuously quantified by the nuclear belt scale or the electronic belt scale 3, and enters the molten pool smelting antimony smelting furnace 4 to be melted and Reduction and slagging reactions occur; negative pressure is maintained in the molten pool smelting antimony smelting furnace, the liquid level maintains a molten pool of 600-1000mm, and the temperature maintains 900-1200°C. By adjusting the gas flow in the spray gun 6 of the molten pool smelting antimony Control the furnace temperature so that the materials entering the furnace melt in a short time, and undergo reduction and slagging reactions; the strong reducing atmosphere in the furnace is controlled by the amount of coke in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com