Method for alloying manganese ore in LF (ladle furnace)

A manganese ore and alloying technology, which is applied in the field of steelmaking production, can solve the problems of many factors affecting the recovery rate of Mn, difficulty in alloying, and low Mn content in poor manganese ore, so as to achieve good slag removal effect and reduce lining Erosion, the effect of stable recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the present invention is applied to a 50tLF furnace, and the type of smelted steel is hard wire steel, and the steel grade is 45#.

[0021] The main components of manganese ore: Mn45%, SiO 2 9.8%, H 2 O3%; main components of silicon-manganese alloy: Mn66%, Si17%; main components of 55 silicon carbide: SiC55%, free C17%, free SiO 2 17%; lime: effective CaO85%.

[0022] At present, the prices of various materials are: manganese ore: 1830 yuan / t; silicon-manganese alloy: 7900 yuan / t; 55% silicon carbide: 2600 yuan / t; lime: 500 yuan / t; wollastonite: 1600 yuan / t t; fluorite: 1000 yuan / t; electricity fee: 0.52 yuan / kwh.

[0023] In the refining process of the LF furnace, 200kg of manganese ore (137kg of silicon-manganese alloy, 170kg of wollastonite and 80kg of fluorite can be replaced), 300kg of lime and 200kg of silicon carbide are added, and the power consumption increases by 250kwh.

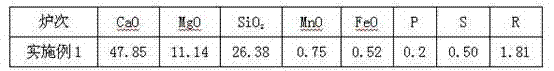

[0024] The composition of refining slag is:

[0025]

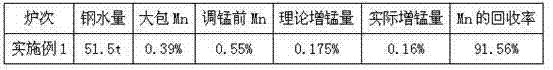

[0026] Mang...

Embodiment 2

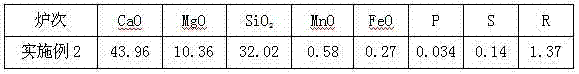

[0032] The invention is applied to a 50tLF furnace, and the smelted steel is welding wire steel, and the steel number is ER70S-6.

[0033] Manganese ore main components: Mn45%, SiO 2 9.8%, H 2 O3%; low-carbon low-phosphorus silicon-manganese alloy main components: Mn62%, Si26%; low-aluminum ferrosilicon main components: Si75%; 75 silicon carbide main components: SiC75%; lime: effective CaO85%.

[0034] At present, the prices of various materials are: manganese ore: 1830 yuan / t; low-carbon and low-phosphorus silicon-manganese alloy: 8600 yuan / t; low-aluminum ferrosilicon: 8500 yuan / t; 75% silicon carbide: 3200 yuan / t; Lime: RMB 500 / t; Fluorite: RMB 1,000 / t; Electricity fee: RMB 0.52 / kwh.

[0035] In the refining process of the LF furnace, 250kg of manganese ore (which can replace 195kg of low-carbon and low-phosphorus silicon-manganese alloy and 80kg of fluorite), 420kg of low-aluminum ferrosilicon, 380kg of lime, and 66kg of silicon carbide are added, and the power consumpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com