Process for preparing choline glycerophosphatide (GPC) with non-aqueous phase enzymatic method

A technology of glycerophosphocholine and enzymatic preparation, which is applied in the direction of fermentation, can solve the problems of expensive reagents, high environmental pollution, difficult control of reaction conditions, etc., achieve mild conditions, high yield, and change the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

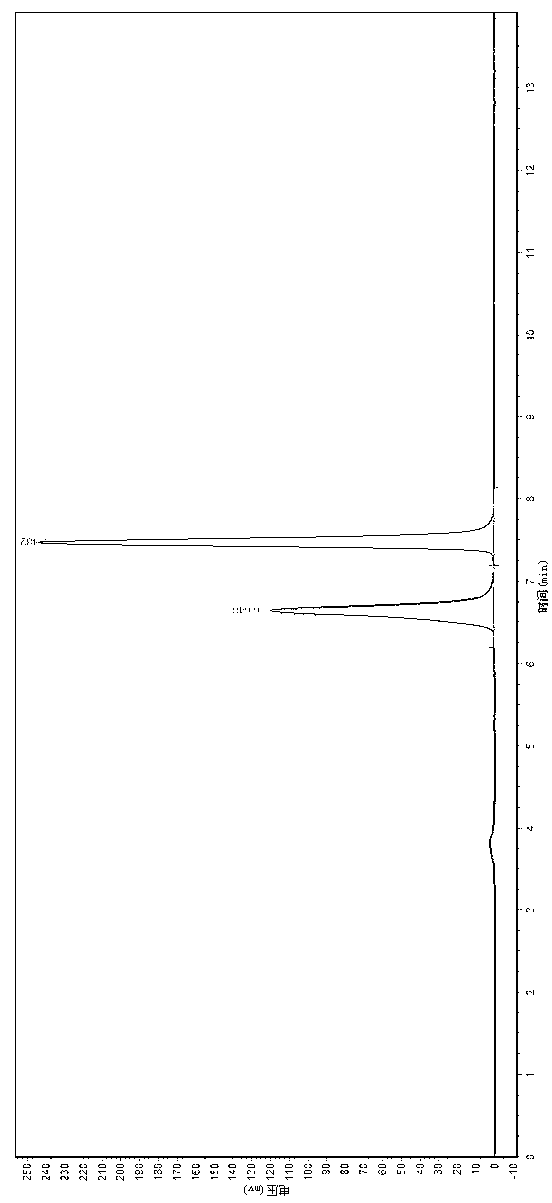

Image

Examples

Embodiment 1

[0022] Take 5g of soybean lecithin (PC50) and ultrasonically dissolve it in 41ml of heptane solvent, then add dropwise the enzyme solution containing 2.5ml of phospholipase A1 and 10ml of acetic acid / sodium acetate buffer solution of pH5.0, and place it at 40 Stir and react at constant temperature for 4 hours at ℃, take out the reaction solution, and then take an extraction agent equal to the volume of the reaction solution, that is, CH 3 OH and distilled water mixed solvent for extraction (CH in the extractant 3 OH and distilled water volume ratio 1:1.5), take the lower layer of water, concentrate and dry to get the GPC product; the crude GPC product obtained after the reaction liquid is extracted and purified can be qualitatively analyzed and detected by TLC method: the selected developing agent is: dichloro Methane:methanol:triethylamine=35:60:5, after the sample was spotted and developed, its Rf value was calculated to be 0.28 by comparing it with the GPC standard. At the...

Embodiment 2

[0025] Take 5g of egg yolk lecithin (PC70) and ultrasonically dissolve it in 41ml of heptane solvent, then add dropwise the enzyme solution containing 2.5ml of phospholipase A1 and 5ml of acetic acid / sodium acetate buffer solution with pH4.0, and place it at 40 Stir and react at constant temperature for 4 hours at ℃, take out the reaction solution, and then take an extraction agent equal to the volume of the reaction solution, that is, CH 3 OH and distilled water mixed solvent for extraction (CH in the extractant 3 OH and distilled water volume ratio 1:1.5), after extraction, the water phase is concentrated and dried to obtain the GPC product; the crude GPC product obtained after the reaction liquid is extracted and purified can be qualitatively analyzed and detected by TLC. First of all, choose a suitable developing agent, so that the GPC and impurities in the sample can be effectively separated on the thin-layer plate. After exploration, the developing agent is finally deter...

Embodiment 3

[0028] Take 5g of soybean lecithin (PC70) and ultrasonically dissolve it in 41ml of heptane solvent, then add dropwise the enzyme solution containing 2.5ml of phospholipase A1 and 5ml of acetic acid / sodium acetate buffer solution of pH4.0, and place it at 40 Stir and react at a constant temperature for 4 hours at ℃, take out the reaction solution, and then take an extraction agent that is 3 times the volume of the reaction solution, that is, CH 3 OH and distilled water mixed solvent for extraction (CH in the extractant 3 OH and distilled water volume ratio 1:1.5), after extraction, the water phase is concentrated and dried to obtain the GPC product; the crude GPC product obtained after the reaction liquid is extracted and purified can be qualitatively analyzed and detected by TLC. First of all, choose a suitable developing agent, so that the GPC and impurities in the sample can be effectively separated on the thin-layer plate. After exploration, the developing agent is finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com