Multi-stage membrane distillation treating method for ammonia nitrogen wastewater

A technology of ammonia nitrogen wastewater and membrane distillation, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high treatment cost, high temperature of wastewater, etc. Small, effective, fast-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

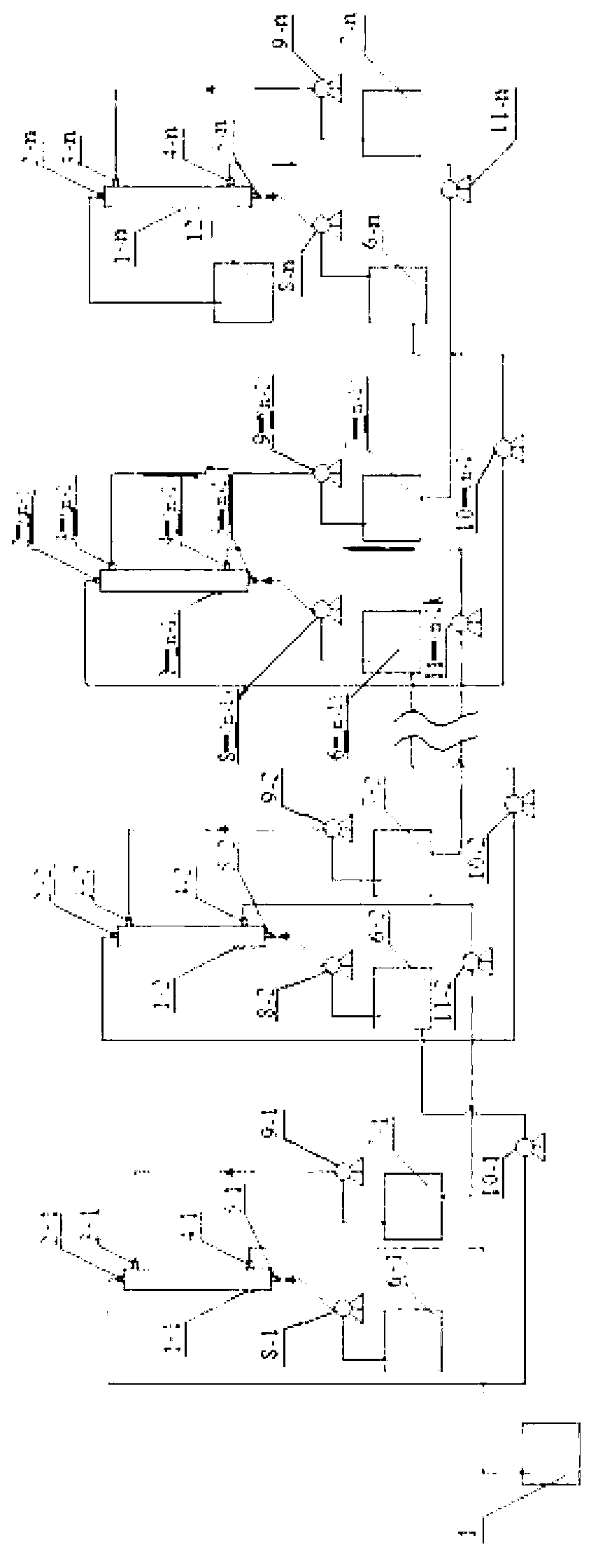

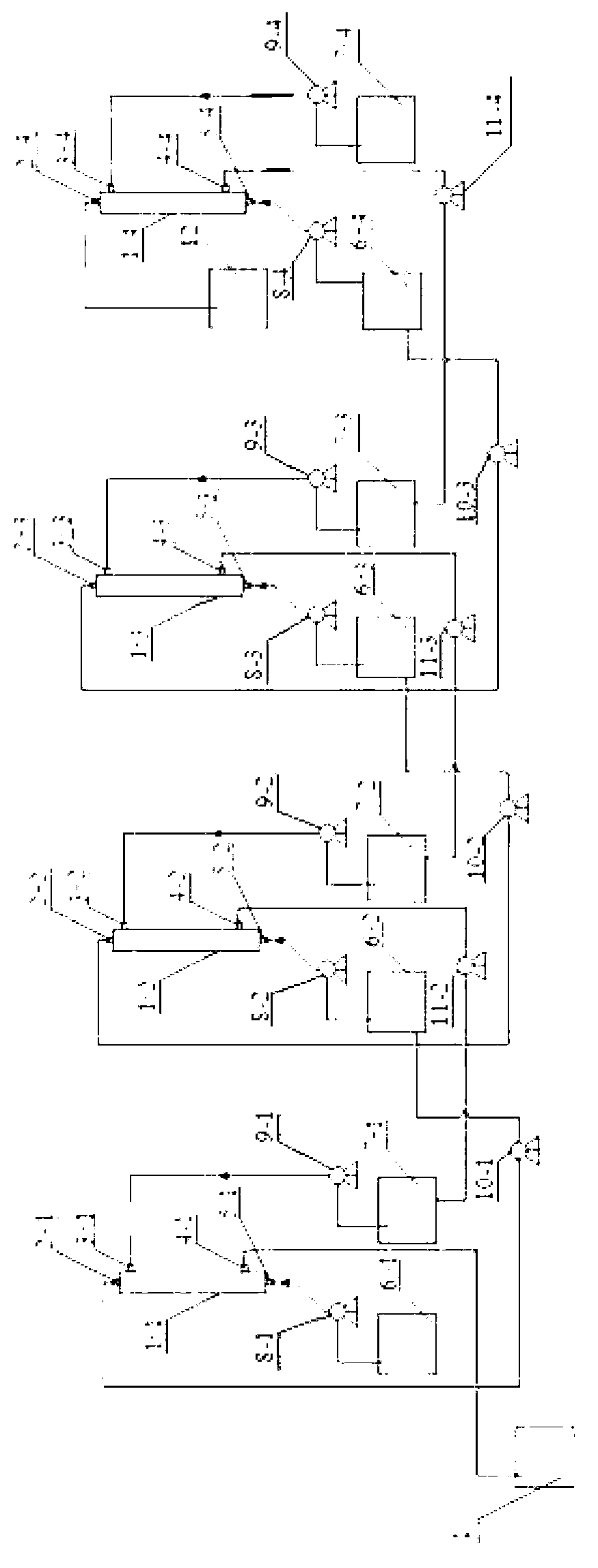

[0023] Specific embodiment one: the method for treating ammonia nitrogen wastewater by multi-stage membrane distillation in this embodiment is carried out according to the following steps:

[0024] 1. Adjust the pH value of the ammonia nitrogen wastewater in the primary raw water pool 6-1 to 11-12;

[0025] 2. Pass the ammonia nitrogen wastewater in the primary raw water pool 6-1 treated in step 1 through the raw water inlet 5 of the primary membrane distillation module 1-1 by the primary raw water pump 8-1 at a flow rate of 500L / h~1000L / h -1 enters the first-level membrane distillation component 1-1, and the water is discharged from the raw water outlet 2-1 of the first-level membrane distillation component 1-1. -2;

[0026] 3. Adjust the pH value of the ammonia nitrogen wastewater in the secondary raw water pool 6-2 to 11-12;

[0027] 4. Pass the ammonia nitrogen wastewater in the secondary raw water pool 6-2 treated in step 3 through the raw water inlet 5 of the secondary...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pH value of the ammonia nitrogen wastewater in the raw water pool (6-1) is adjusted to 11.5 in step 1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass concentration of the acid solution described in step 9 is 3%. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com