Filter with squeezing filtering bags

A filter machine and filter bag technology, applied in the direction of fixed filter element filter, filter separation, gravity filter, etc., can solve the problems of easily damaged rigid filter screen, high requirements, cumbersome filter work, etc., to reduce the need to replace the filter The effect of the number of bags, prolonging the filtration time, and avoiding the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

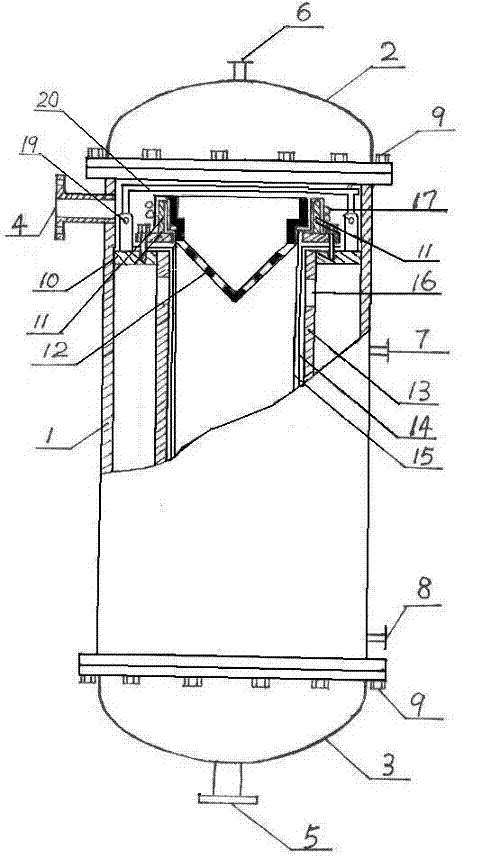

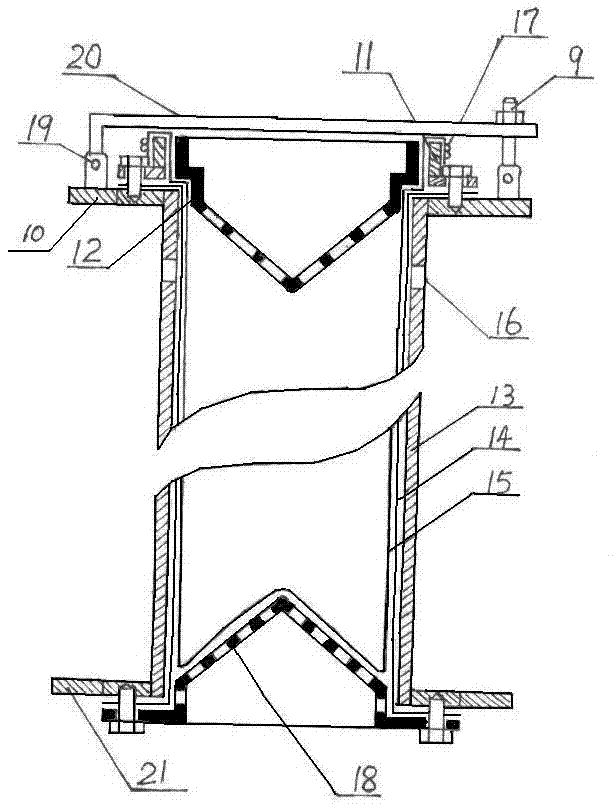

[0023] Embodiment 1: a kind of squeezing type filter bag filter (see Figure 1-Figure 3 ), which is especially suitable for filtering the turbid liquid that needs to be filtered with low solid content. It includes a cylinder body 1, the cylinder body 1 is connected with the upper head 2 and the lower head 3 through bolts 9 respectively, and the upper head 2 is provided with There is an exhaust port 6, the bottom of the lower head 3 is provided with a discharge port 5, the cylinder body 1 is provided with a feed port 4, a press medium outlet 8, a press medium inlet 7, an upper head 2, a lower head 3 and The cylinder body 1 forms the integral sealing structure of the filter. Cylinder body 1 is provided with at least one filter press device (the filter press device of this embodiment is 1, see figure 2 ), each filter press device includes an upper orifice plate 10 and a lower orifice plate 21, a rigid pipe 13 is connected between the upper orifice plate 10 and the lower orifice...

Embodiment 2

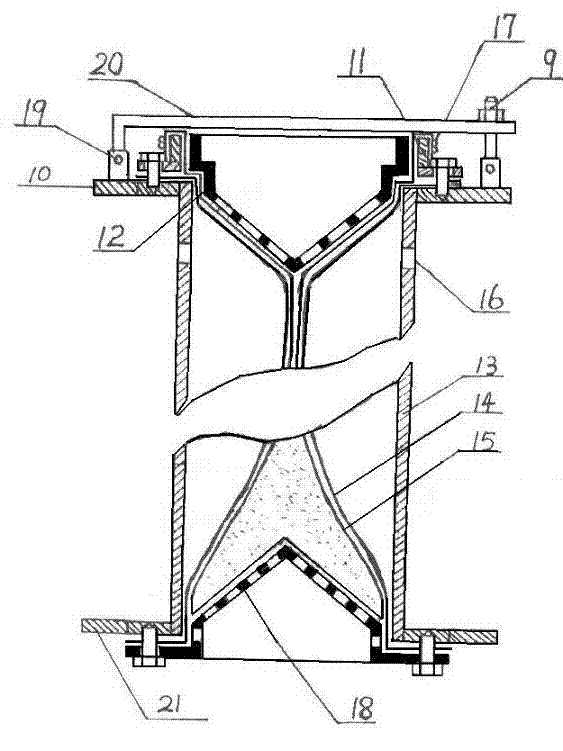

[0025] Embodiment 2: a kind of squeezing type filter bag filter (see Figure 4 , Figure 5 ), which can clean and regenerate the filter bag in time during the filtering process, prolonging the working time of the filter bag. It includes a cylinder 1, the upper and lower sides of the cylinder 1 are respectively connected with the upper head 2 and the lower head 3 by bolts 9, the upper head 2 is provided with an exhaust port 6, and the bottom of the lower head 3 is provided with a discharge port 5, The cylinder body 1 is provided with a feed inlet 4, a squeeze medium outlet 8, and a squeeze medium inlet 7. The upper head 2, the lower head 3 and the cylinder body 1 form an integral sealing structure of the filter. Cylinder body 1 is provided with at least one filter press device (the filter press device of the present embodiment is 1), and each filter press device all comprises upper orifice plate 10 and lower orifice plate 21, and upper orifice plate 10 and lower orifice plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com