Light and thin type solar photovoltaic component and producing method thereof

A solar photovoltaic and production method technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of aging and poor appearance of solar panels, and achieve the effect of reducing the probability of delamination, reducing contact, and slowing down aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

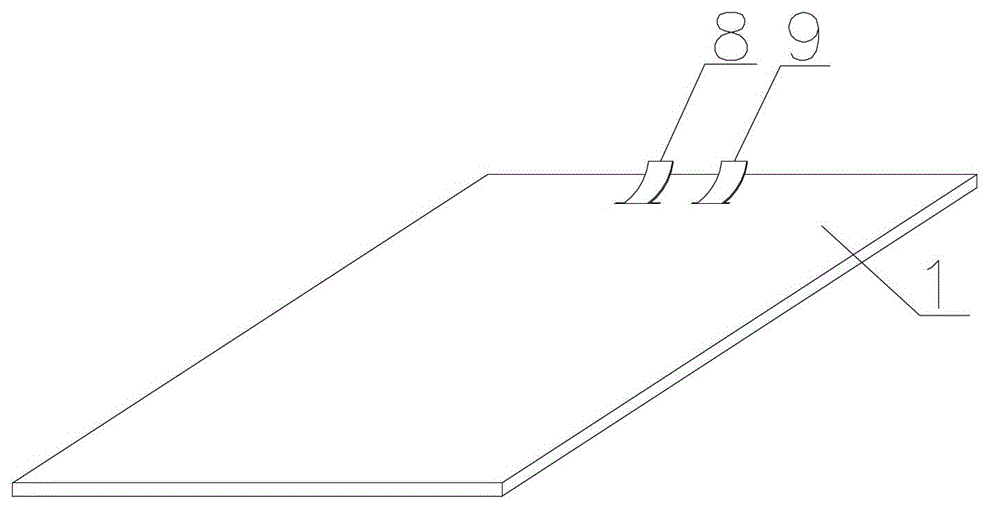

[0024] Embodiment one, such as figure 2 As shown, openings are drawn on the surface of the transparent PET film 1, and the positive electrode lead 8 and the negative electrode lead 9 are drawn from the openings on the surface of the transparent PET film 1 to the outside of the light and thin solar photovoltaic module.

Embodiment 2

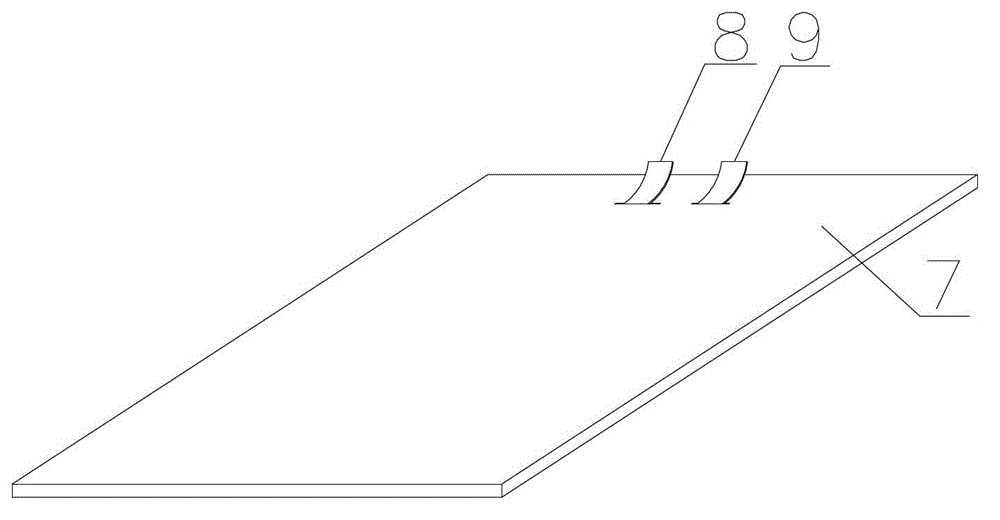

[0025] Embodiment two, such as image 3 As shown, openings are drawn on the surface of the waterproof cloth 7, and the positive electrode lead 8 and the negative electrode lead 9 are drawn out of the openings on the surface of the waterproof cloth 7 to the outside of the light and thin solar photovoltaic module.

Embodiment 3

[0026] Embodiment three, such as Figure 4 As shown, the positive electrode lead 8 and the negative electrode lead 9 are drawn out from the side along the plane of the solar cell string 3 to the outside of the light and thin solar photovoltaic module.

[0027] The production method of light and thin solar photovoltaic module has the following steps:

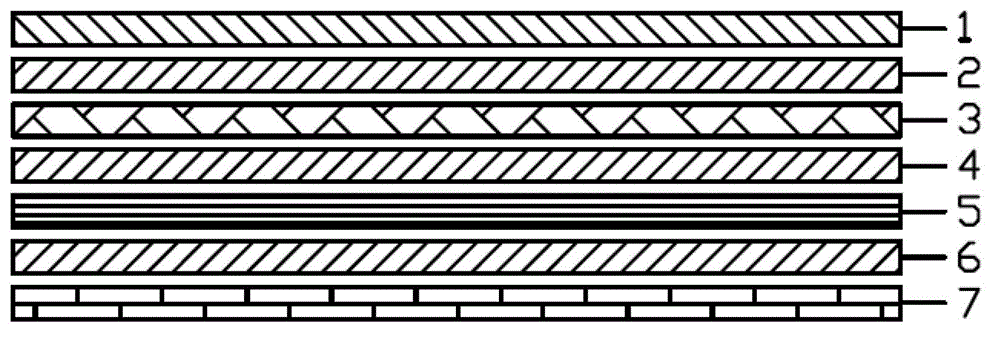

[0028] a. Lamination: Take a piece of ultra-clear tempered glass and place it flat on the workbench, lay transparent PET film 1, upper layer EVA2, welded solar cell string 3, middle layer EVA4, epoxy resin on the ultra-white tempered glass from bottom to top Resin board 5, lower floor EVA6 and waterproof cloth 7, use scotch tape to fix the surroundings of the uppermost waterproof cloth 7 on the ultra-white tempered glass, and finally lay high-temperature cloth on the waterproof cloth 7;

[0029] b. Lamination: Put the stacked photovoltaic modules into a laminator for lamination. After lamination, remove the ultra-clear tempered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com