Production method of recycled phosphorus flame retardant polyester staple fibre

A polyester staple fiber and phosphorus-based flame retardant technology is applied in the production field of recycled polyester modified fibers, which can solve the problems of reduced flame retardant effect and unsatisfactory flame retardant effect, achieves good flame retardant effect, and has significant economic and social benefits. , the effect of environmental protection added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

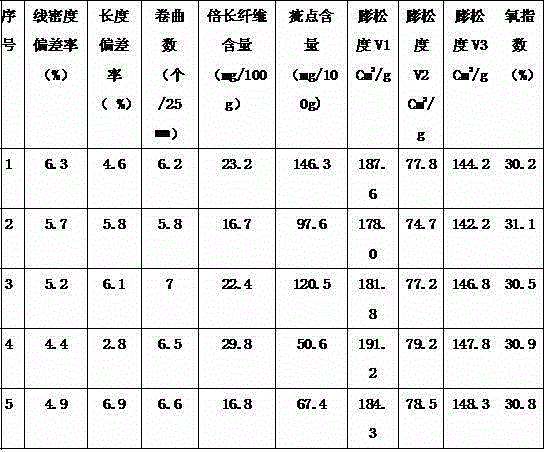

Examples

Embodiment 1

[0013] Example 1: Preparation of phosphorus-based flame-retardant masterbatch. The ratio of raw materials is: 10-12wt% of 2-carboxyethylphenylphosphinic acid (phosphorus flame retardant) and 90-88wt% of waste polyester PET bottle flakes. Put the waste polyester PET bottle flakes into the drum dryer and dry for 2 hours, then add 2-carboxyethylphenylphosphinic acid (powder) to mix and continue drying (without vacuum drying) for more than 6 hours, the drying temperature is 110-115 °C, after drying, the moisture content is within 0.015%, and after drying, it is added to the screw extruder, melted and extruded to granulate. The temperature of the granulation screw is 240-275°C, the speed of the main machine is 50-80 rpm, the feeding speed is 80-120 kg / hour, the speed of the granulator is 25-30Hz, and the specification of the masterbatch is Φ3.5-4.5㎜.

Embodiment 2

[0014] Example 2: Add the flame-retardant masterbatch and waste polyester PET bottle flakes into the vacuum drum dryer respectively, the drying temperature of the flame-retardant masterbatch is 115-125°C, and the drying temperature of the waste polyester PET bottle flakes is 145-145°C 155℃, the drying time is more than 9 hours, and the moisture content is controlled within 0.008wt%.

Embodiment 3

[0015] Example 3: Put 8-10wt% of flame-retardant masterbatch into automatic masterbatch adding equipment and 90-92wt% of waste polyester PET bottle flakes according to the weight ratio, and add the screw extruder to melt, filter, and spin to prepare semi-finished flame-retardant Burning fiber, and then post-processing drafting, crimping and setting, drying, cutting and packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com