Environmentally-friendly cleaning agent and preparation method thereof

A cleaning agent and environment-friendly technology, applied in the field of environment-friendly cleaning agent for nuclear power equipment cleaning and its preparation, can solve the problems of fast volatilization, difficulty in purchasing, poor safety, etc., and achieve the effect of strong cleaning ability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

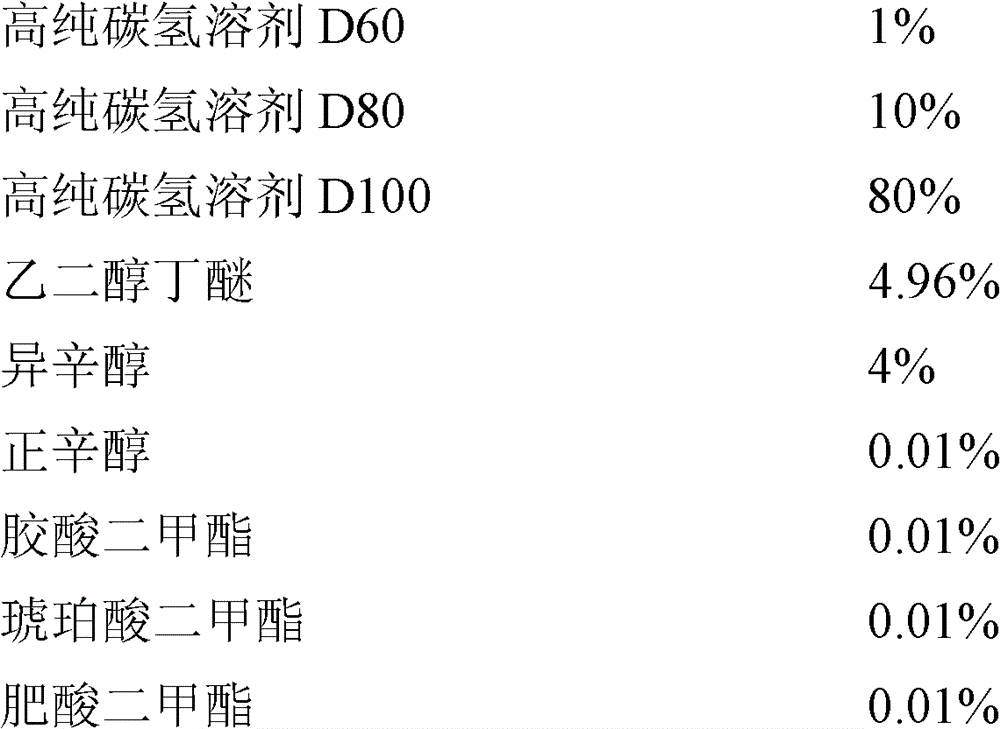

Embodiment 1

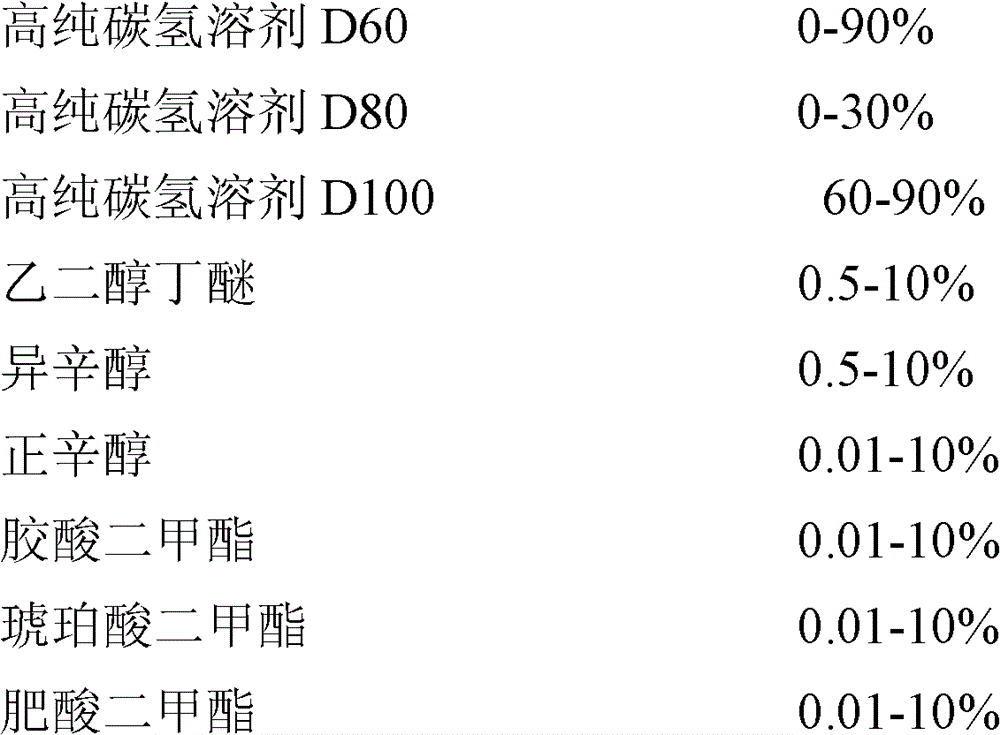

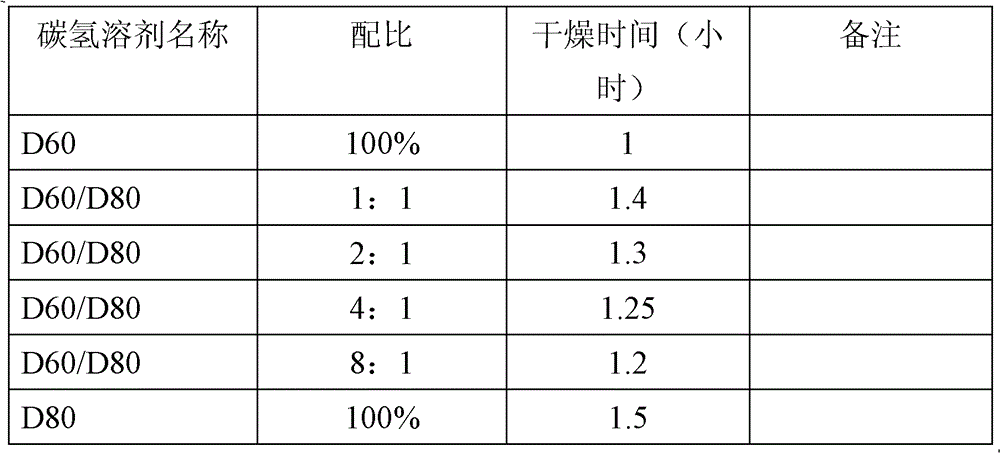

[0029] Hydrocarbon solvents D60 and D80 in different proportions affect the drying rate. (mass fraction%)

[0030] Experimental method: spread a certain amount (0.1g) of hydrocarbon solvent evenly on a certain area (7850mm 2 ) on a watch glass, put it in a blast oven at 25±1°C, record the drying time, and calculate the relative drying time.

[0031] Table 1: Drying time of different ratios of D60 and D80

[0032]

[0033] It can be seen from Table 1 that the volatilization rate of D60 is faster than that of D80. Adding a small amount of D80 to D60 can slow down the solvent drying rate. When the cleaning agent is in the washing tank, it is hoped that the cleaning agent will volatilize slowly to reduce the loss of cleaning agent and improve safety at the same time. After the parts are taken out of the dipping tank, it is desired to dry faster to reduce the drying time and prevent secondary pollution caused by too long drying time.

Embodiment 2

[0035] Sometimes, there are fire points around the cleaning tank. At this time, in order to consider production safety, it is necessary to further reduce the volatility of the solvent, and at the same time consider the viscosity of the solvent to reduce the adhesion to the equipment. Experiment (table 2 is an excerpt of part of the experimental data, and the proportioning is mass percentage)

[0036] Table 2: Effects of different ratios of D60, D80, and D100 on the volatilization rate and viscosity (volatility rate: butyl acetate = 100)

[0037] Hydrocarbon solvent name

Embodiment 3

[0038] Example 3: Influence of cleaning and drying speed of deep hole test blocks of nuclear power equipment.

[0039] In order to achieve the ideal drying speed and obtain a satisfactory ratio, a cleaning and drying test of deep hole test blocks of nuclear power equipment was carried out.

[0040] Experimental method: Prepare a immersion tank and a nuclear power equipment deep-hole test block, first add hydrocarbon solvent into the immersion tank, then immerse the nuclear power equipment deep-hole test block, soak for 10 minutes, take it out, and dry it.

[0041] Table 3: Cleaning and drying of deep hole test blocks of nuclear power equipment (air temperature 12°C)

[0042]

[0043] Considering the test results of Table 1, Table 2, and Table 3 and the actual use, the normal usage amount: the ratio of hydrocarbon solvent D60:D80 is 8:1, which is more suitable. In special cases, the ratio of hydrocarbon solvent D100:D80 is 8:1 is more appropriate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com