Production technology for extracting soybean isoflavone aglycone through enzymatic hydrolysis method

A technology for isoflavone aglycone and production process, which is applied in the field of production process for extraction of soybean isoflavone aglycone by enzymatic hydrolysis, can solve the problems of unfavorable industrial production, low solubility of aglycon, unstable structure of aglycone, etc., and achieve large-scale production , Enzyme reaction time is less, the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The production process for extracting soybean isoflavone aglycone by the enzymatic hydrolysis method of the present invention will be described in detail below.

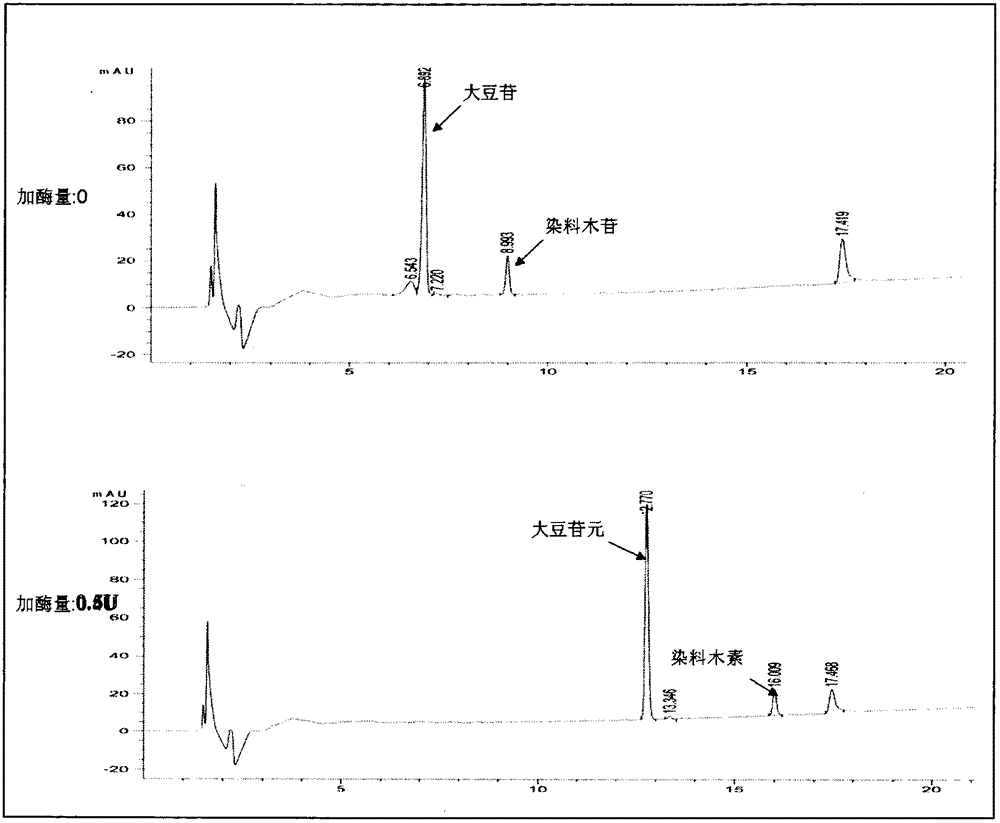

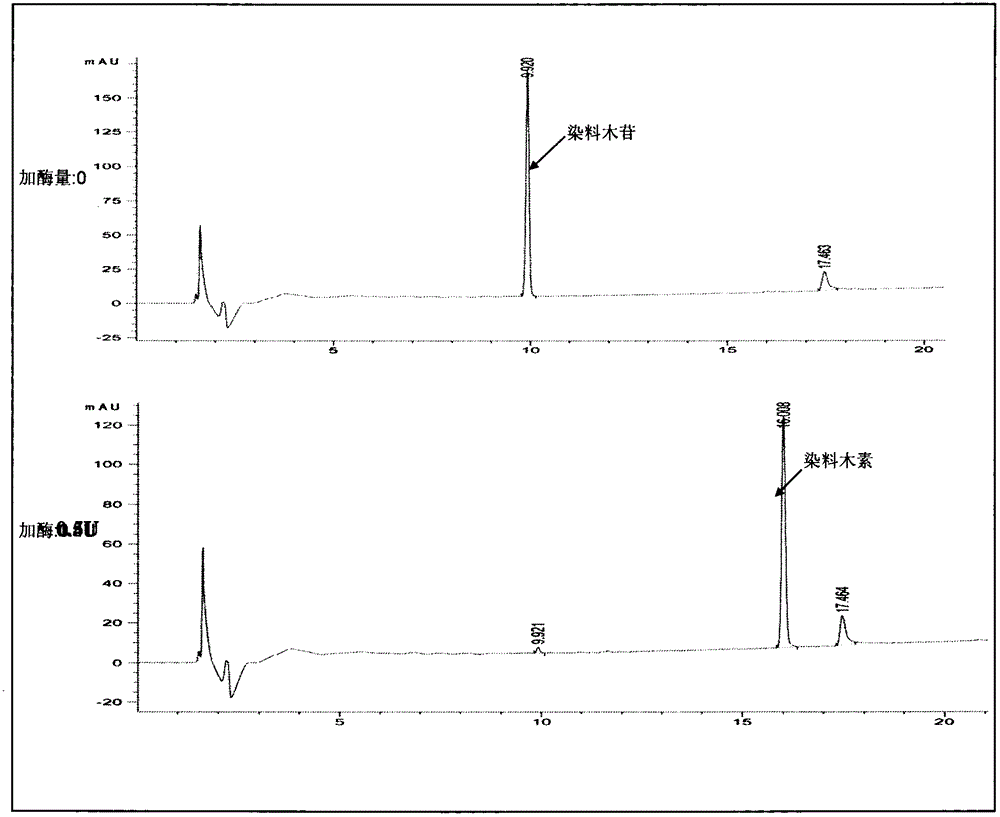

[0023] The production process of the present invention for extracting soybean isoflavone aglycone by enzymatic hydrolysis, the process steps are: the defatted soybean meal comes from the leftover soybean soybean meal of the oil factory, soak the defatted soybean meal, the ratio of material to water is 5-10:1, and add ethanol to the soaking liquid Until ethanol accounts for 10% of the mass concentration of the total soaking solution, the soaking solution is hydrolyzed with ultra-high temperature β-glucosidase, and the ultra-high temperature β-glucosidase uses yeast β-glucosidase. The addition amount of ultra-high temperature β-glucosidase is 0.5U / mL soaking solution, the hydrolysis temperature is 90°C-120°C, the pH range of soaking solution hydrolysis is 4.5-8.0, stir slowly while hydrolyzing, and after 1-2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com