Matched cleaning agent for vacuum drainage pipelines of airplane toilets and preparation method and cleaning process of matched cleaning agent

A sewage pipeline and cleaning agent technology, which is applied in the aerospace field, can solve the problems of cleaning operators such as hazards, short residence time, and heavy sour taste, so as to improve the cleaning effect and efficiency, ensure the cleaning action time, and improve the cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

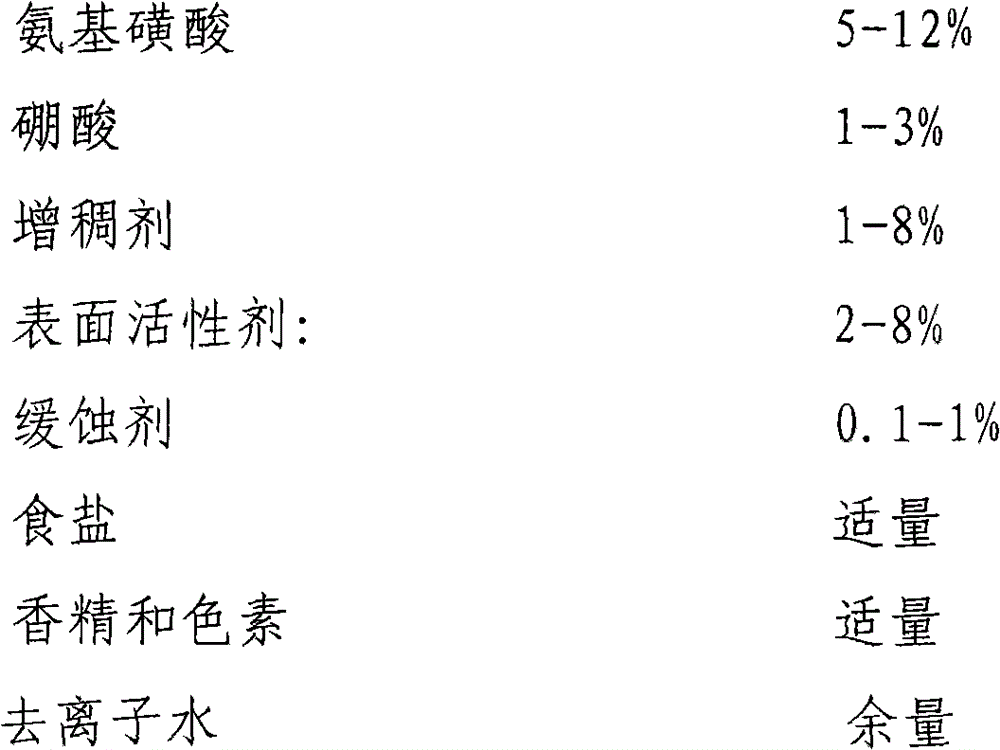

[0049] No. I cleaning agent:

[0050] Sulfamic acid: 5%;

[0051] Boric acid: 2%;

[0052] DS-45: 4%;

[0053] PNP: 4%;

[0054] Corrosion inhibitor: 0.5%;

[0055] Salt: Appropriate amount;

[0056] Pigment and flavor: appropriate amount;

[0057] Balance: deionized water;

[0058] The total weight of the above components is 100%.

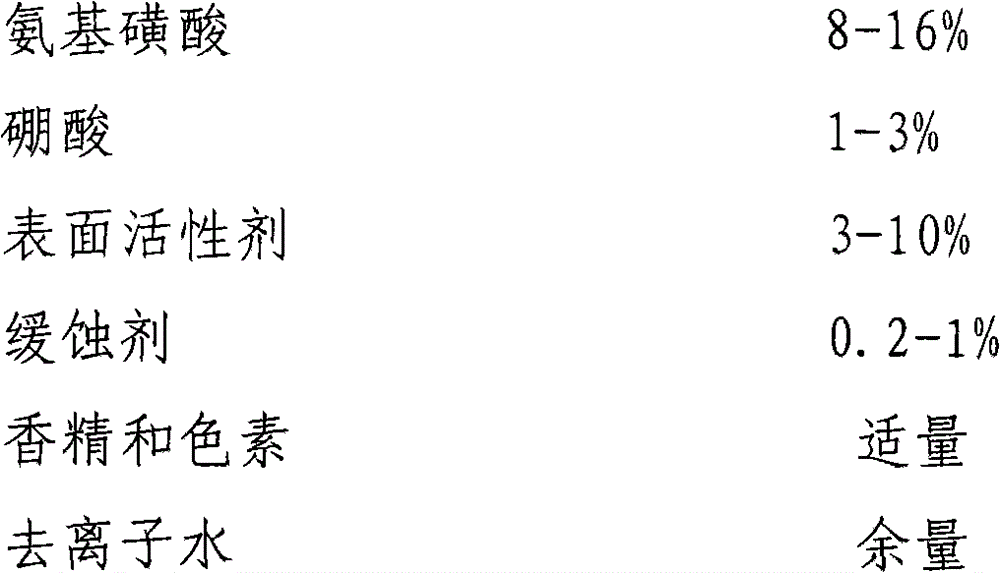

[0059] Cleaning Agent II:

[0060] Sulfamic acid: 12%;

[0061] Boric acid: 2%;

[0062] PNP: 4%;

[0063] Corrosion inhibitor: 0.5%;

[0064] Pigment and flavor: appropriate amount;

[0065] Balance: deionized water;

[0066] The total weight of the above components is 100%.

Embodiment 2

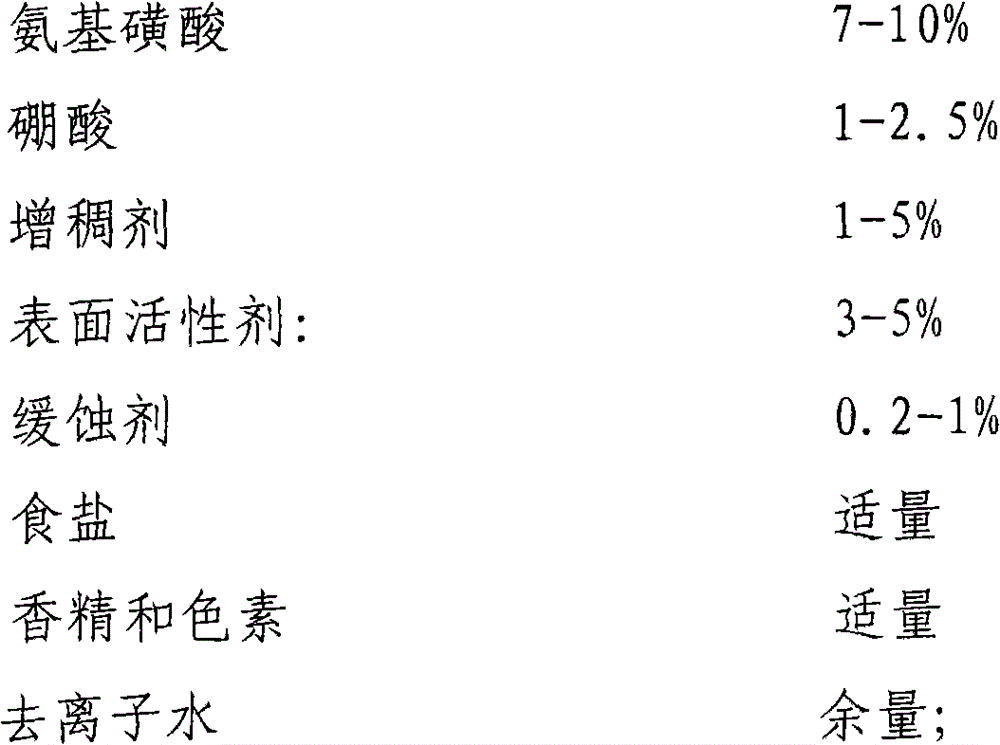

[0068] No. I cleaning agent:

[0069] Sulfamic acid: 12%;

[0070] Boric acid: 1%;

[0071] DS-45: 8%;

[0072] PNP: 5%;

[0073] Corrosion inhibitor: 1%;

[0074] Salt: Appropriate amount;

[0075] Pigment and flavor: appropriate amount;

[0076] Balance: deionized water;

[0077] The total weight of the above components is 100%.

[0078] Cleaning Agent II:

[0079] Sulfamic acid: 15%;

[0080] Boric acid: 1%;

[0081] PNP: 10%;

[0082] Corrosion inhibitor: 0.8%;

[0083] Pigment and flavor: appropriate amount;

[0084] Balance: deionized water;

[0085] The total weight of the above components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com