ABS thermoplastic resin composition

A thermoplastic resin, ABS resin technology, applied in the field of ABS thermoplastic resin composition, can solve the problems of inability to produce, difficult to obtain raw materials, impact strength, low gloss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

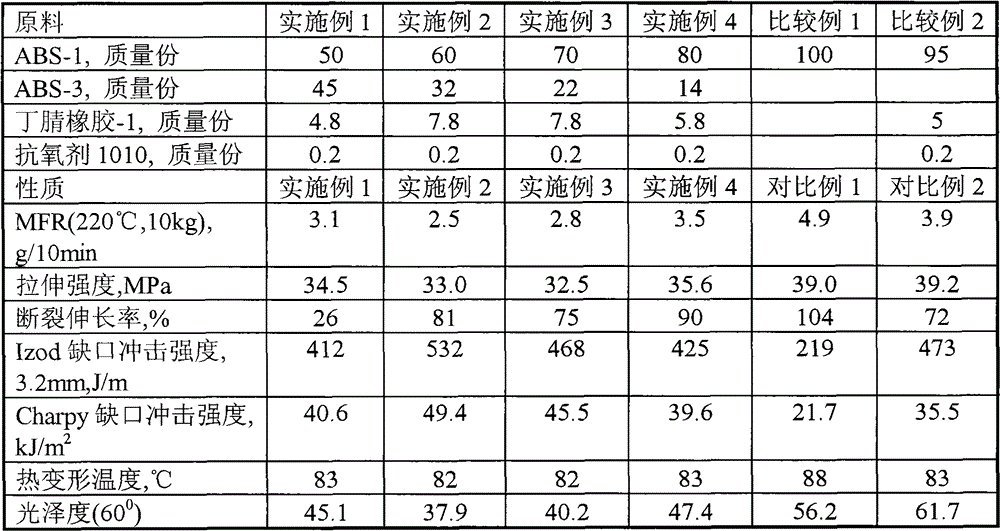

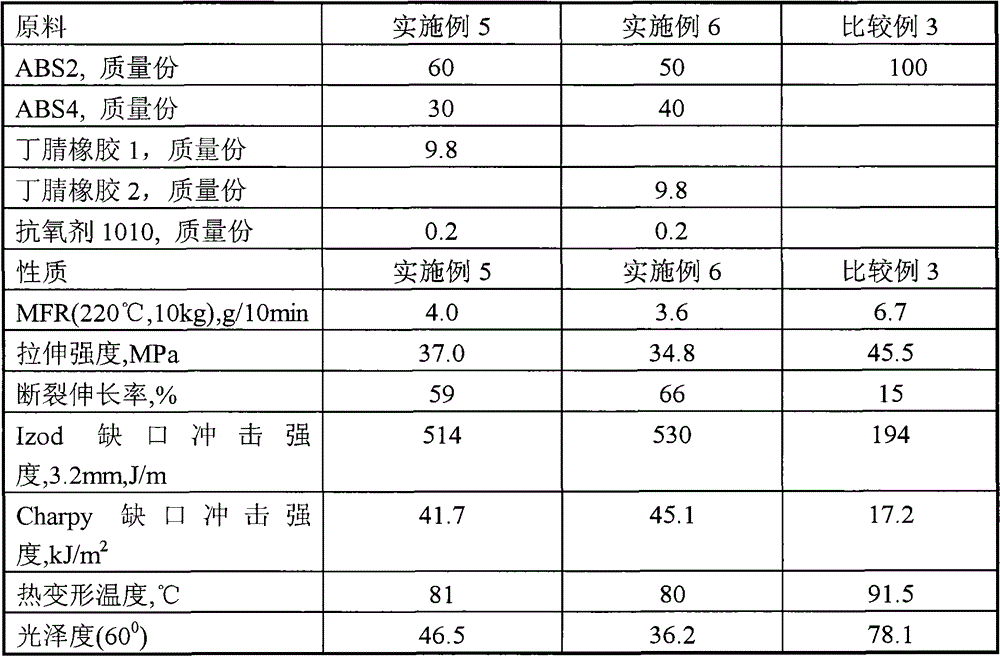

Embodiment 1

[0041] Weigh 2.000 kilograms of dried bulk polymerization ABS resin (ABS-1), 1.800 kilograms of emulsion polymerization ABS resin (ABS-3), 0.192 kilograms of nitrile rubber-1 and 10 grams of antioxidant 1010, and put them into a container Use a mixer to mix evenly, and then add it to the feeder of the twin-screw extruder for later use. Twin-screw extruder (screw diameter 27mm, length / diameter ratio 36, Germany Leistritz company) barrel temperature is set in ten sections from the feed inlet to the extrusion outlet at 200°C, 210°C, 220°C, 225°C, 230°C , 230°C, 230°C, 230°C, 230°C, 228°C, when the temperature of each section reaches the set value, turn on the main screw and feeder screw, the speed of the main screw is 160 rpm, and the speed of the feeder screw is 60 rpm Minutes, extrude the above-mentioned material into strips at a rate of about 9 kilograms per hour, and cut into pellets after cooling in a water tank to obtain the product.

[0042] The above product was dried at...

Embodiment 2

[0045] Weigh 2.400 kilograms of dried bulk polymerization ABS resin (ABS-1), 1.280 kilograms of emulsion polymerization ABS resin (ABS-3), 0.312 kilograms of nitrile rubber-1 and 10 grams of antioxidant 1010, and put them into a container Mixed evenly with a stirrer, then added to the feeder of the twin-screw extruder to prepare the composition, injection molding sample preparation and test performance under the same conditions as in Example 1, the results are shown in Table 1.

Embodiment 3

[0047] Weigh 2.800 kg of dried bulk polymerization ABS resin (ABS-1), 0.880 kg of emulsion polymerization ABS resin (ABS-3), 0.312 kg of nitrile rubber-1 and 10 grams of antioxidant 1010, and put them into a container Mixed evenly with a stirrer, then added to the feeder of the twin-screw extruder to prepare the composition, injection molding sample preparation and test performance under the same conditions as in Example 1, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com