Friction plate milling machine

A friction plate and grinding machine technology, applied in the field of machinery, can solve the problems of product straightness, flatness, verticality and concentricity cannot be well guaranteed, low efficiency, etc. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

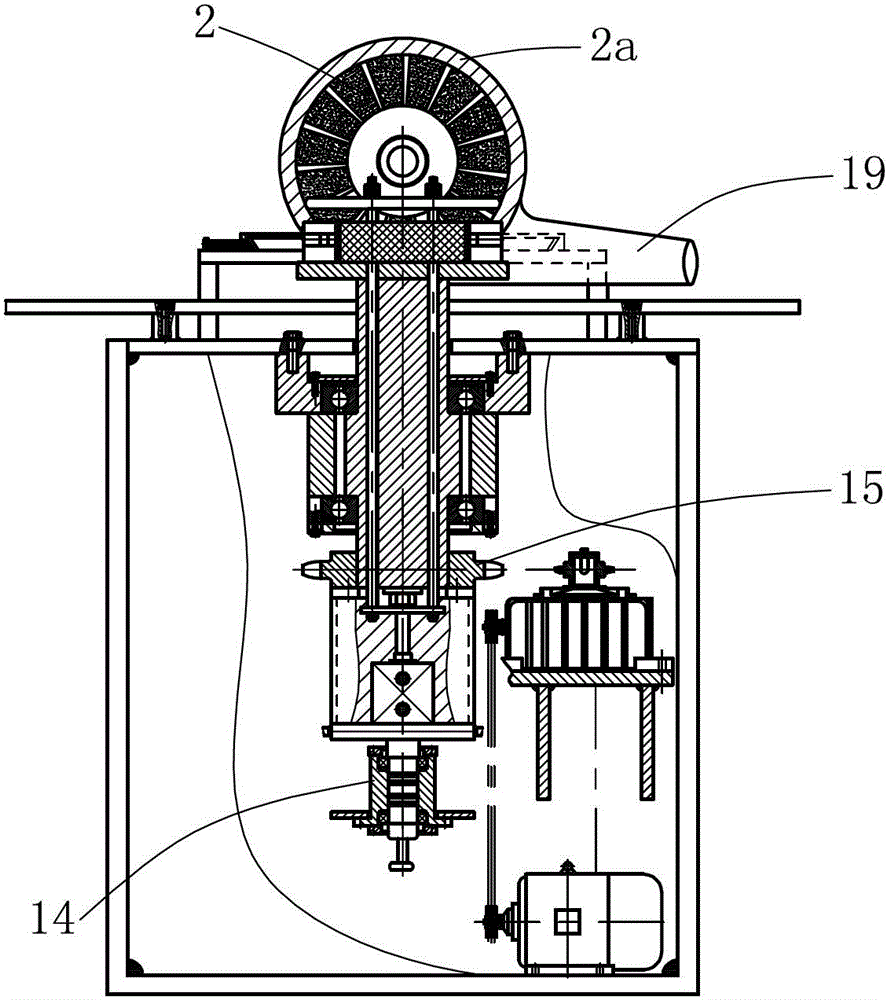

[0012] Such as figure 1 , figure 2 The friction disc grinding machine shown is mainly composed of frame assembly 1, grinding wheel 2, grinding wheel drive motor 3, "⊥" shaped round table 4, part positioning plate 5, part rotating spindle 6, screw rod 7, bearing seat 9, thin Cylinder 10, pneumatic pressure plate 11, parts pressing and connecting pull rod 12, pressure plate pneumatic reversing sensor contact 13, pressure plate pneumatic commutator 14, sprocket chain mechanism 15, worm gear and worm speed changer 16 and other components.

[0013] The grinding wheel 2 and the grinding wheel driving motor 3 are arranged above the frame assembly 1 , the axis of the grinding wheel 2 is arranged horizontally, and the grinding wheel driving motor 3 is positioned at the rear of the grinding wheel 2 . The front of the grinding wheel 2 is a workbench 1a, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com