Hydraulic shock absorber

A shock absorber, hydraulic technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as reduced sealing, reduced oil outflow, and reduced buffer capacity, and achieves good sliding properties , The effect of improving durability and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

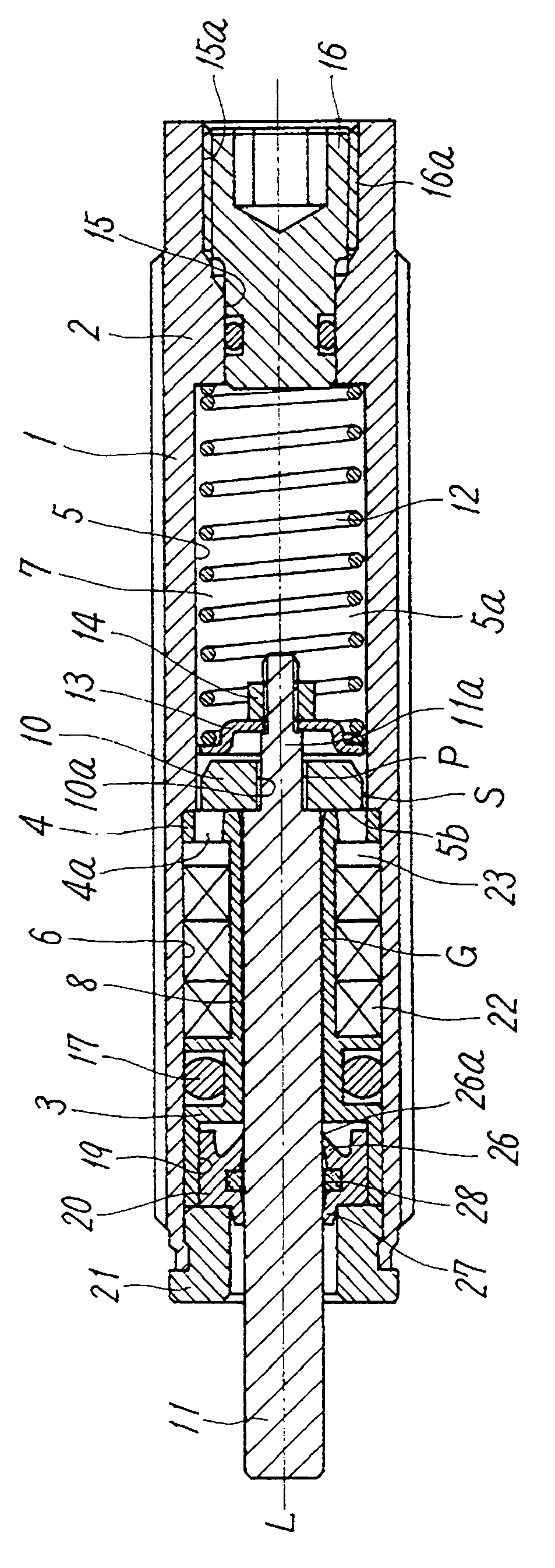

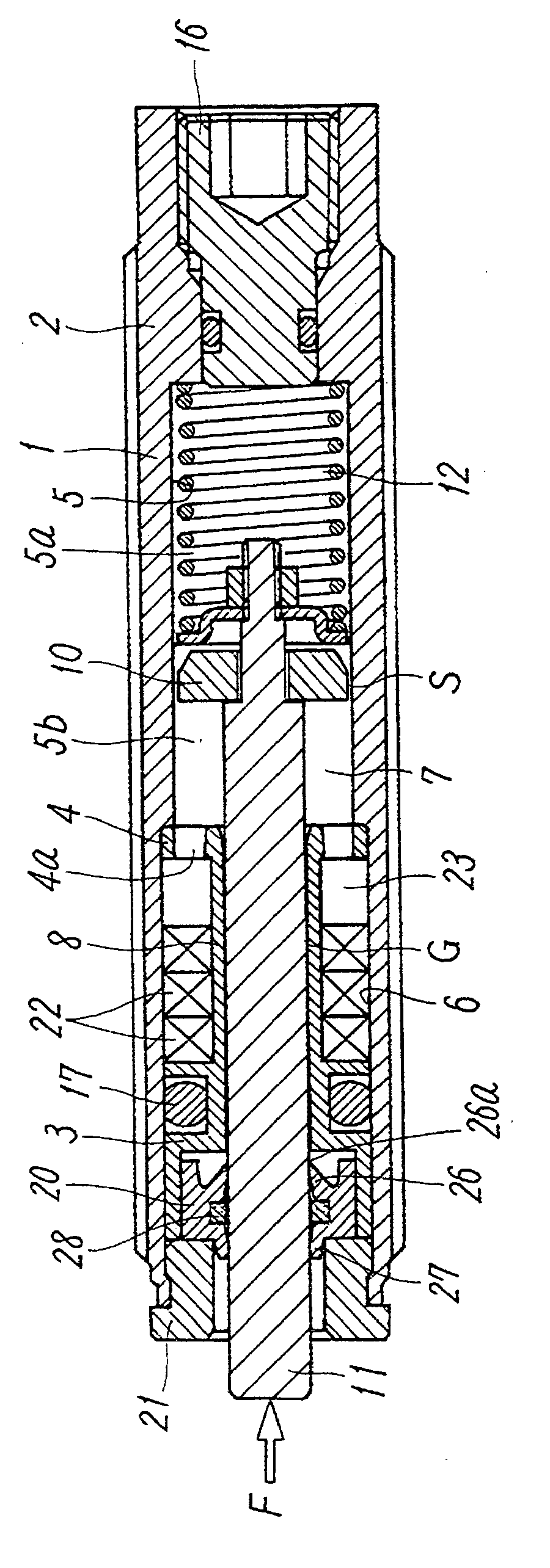

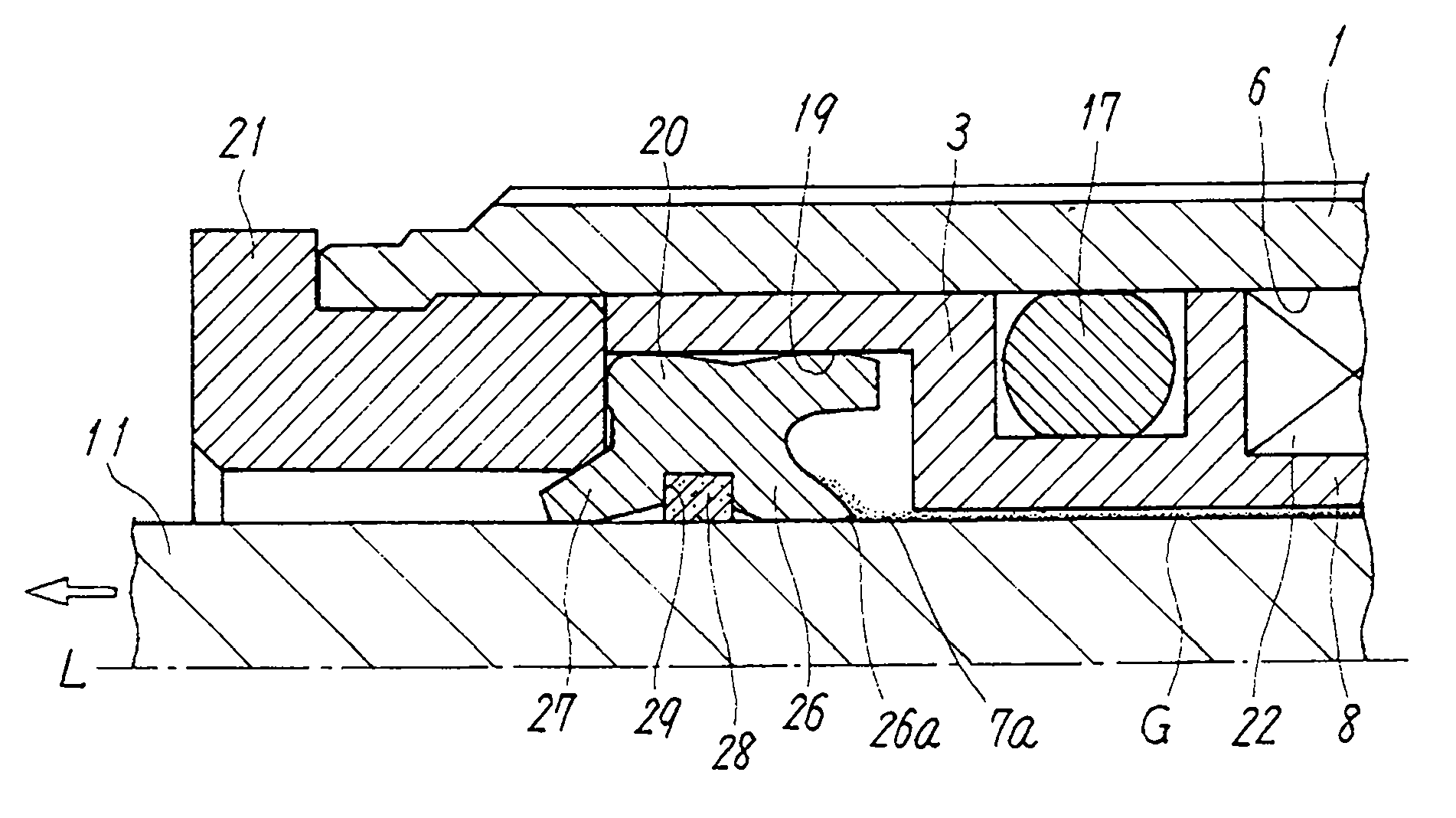

[0024] Figure 1-Figure 3 It is a figure which shows the 1st Embodiment of the hydraulic shock absorber of this invention. This shock absorber has a cylindrical cylinder housing 1 . The cylinder housing 1 has a cover-side end wall 2 located on the base end side in the axis L direction, a piston rod-side end wall 3 located on the front end side, and an intermediate wall 4 located in between. A piston chamber 5 is formed between the two, and an accumulator chamber 6 is formed between the intermediate wall 4 and the rod-side end wall 3, and the piston chamber 5 and the accumulator chamber 6 are filled with oil 7 in a pressurized state. The piston chamber 5 and the accumulator chamber 6 communicate with each other through the communication hole 4 a of the intermediate wall 4 .

[0025] A buffer piston 10 having a smaller outer diameter than the inner diameter of the piston chamber 5 is mounted on the cylinder housing 1 in a state where a gap S through which the oil 7 flows is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com