Micro-nano composite structure of solar battery photo anode and preparation method thereof

A micro-nano composite structure and solar cell technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as environmental pollution, climate warming, and limited reserves of fossil energy on the earth, and achieve high collection efficiency and light trapping capabilities Strong, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

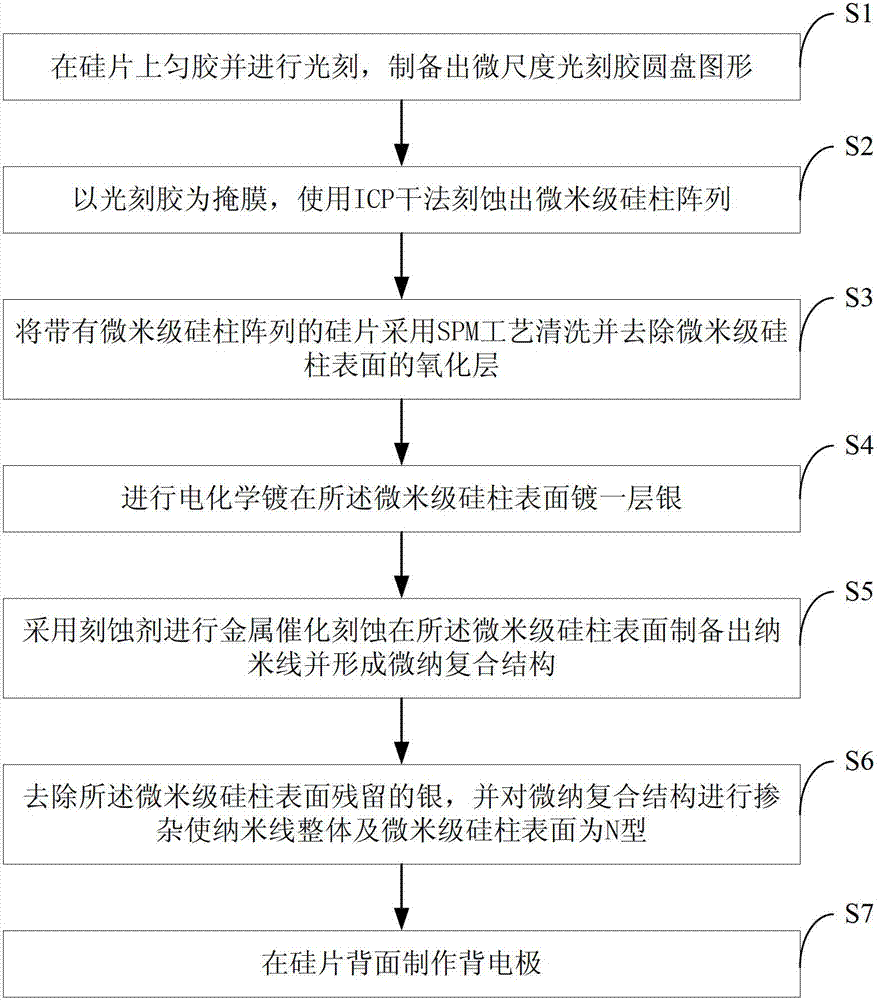

[0033] In the embodiment of the present invention, the process for manufacturing the micro-nano composite structure for the photoanode of the solar cell includes the following specific steps:

[0034] (1) Spread the glue on the cleaned silicon wafer and perform photolithography to prepare a micro-scale photoresist disk pattern distributed in an array, with a diameter of 10 microns, a distance between centers of 20 microns, and a right-angle distribution;

[0035] (2) Using the photoresist as a mask, use the ICP dry method to etch an array of silicon pillars with a diameter of 10 microns;

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com