Flexible supercapacitor and preparation method thereof

A technology for supercapacitors and capacitors, which is applied to capacitors, electrolytic capacitors, hybrid capacitor electrodes, etc., can solve the problems of unsatisfactory carbon-based flexible supercapacitor capacity, poor cycle stability of polymer electrode capacitors, etc., and achieves low cost and preparation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a method for preparing a flexible supercapacitor, the method comprising the following steps:

[0063] 1) Put the carbon-based material in a solution containing a conductive polymer monomer, a dopant and an oxidizing agent, and stir and react at a temperature of -10°C to 20°C for 1-48 hours to obtain an in-situ carbon-based material on the surface of the carbon-based material. Electrodes that generate conductive polymer nanowire arrays;

[0064] 2) Place the two above-mentioned electrodes in the case in such a manner that they are opposed to each other and are spaced apart from each other, and fill an electrolyte solution between the two electrodes.

[0065] According to the method of the present invention, the solution described in step 1) contains the conductive polymer monomer of 0.01-0.1mol / L, the dopant of 0.01-2mol / L and the oxidizing agent of 0.005-1.5mol / L; preferred situation Below, the above solution contains 0.005-0.008mol / ...

Embodiment 1

[0086] This example is used to illustrate the preparation method of the flexible supercapacitor.

[0087] Preparation of carbon-based materials: First, natural graphite was oxidized to graphene oxide by the Hummers method. The process is to mix 5g of flaky natural graphite (Sinopharm Chemical Reagent Co., Ltd.) and 2g of sodium nitrate (Sinopharm Chemical Reagent Co., Ltd.), and add 120mL of concentrated sulfuric acid (98wt%, Sinopharm Chemical Reagent Co., Ltd.) . Stir in an ice bath, and slowly add 15 g of potassium permanganate. After 2-3 hours of reaction, add 300 mL of deionized water to the reaction solution, raise the temperature to 100° C. and continue the reaction for 30 minutes. Then further add 100 mL of deionized water to the reaction solution to dilute the reaction solution, and add 15 mL of hydrogen peroxide solution (30 wt%, Sinopharm Chemical Reagent Co., Ltd.) to neutralize unreacted potassium permanganate. The reaction solution was placed in a probe ultraso...

Embodiment 2

[0091] This example is used to illustrate the preparation method of the flexible supercapacitor.

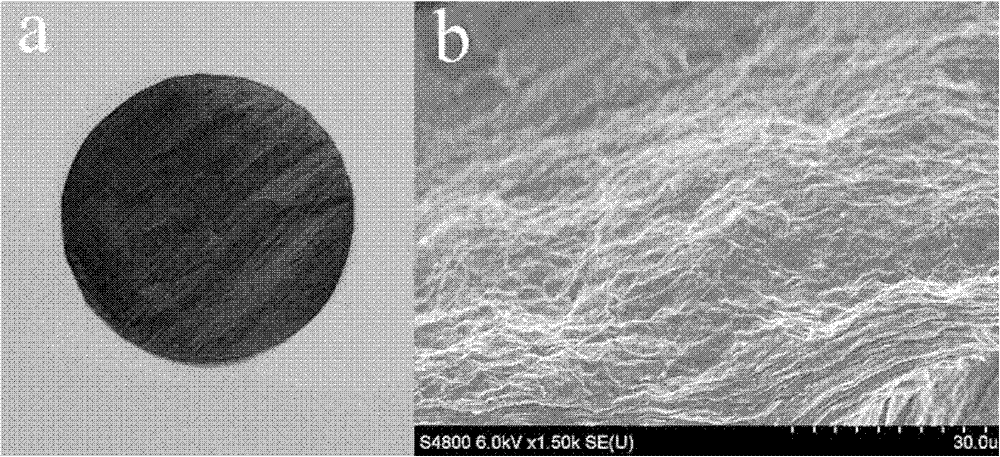

[0092] Preparation of carbon-based materials: The same method as in Example 1 was used to obtain a black graphene dispersion with a concentration of 1 mg / mL. At a temperature of 25°C, take 20mL of the graphene dispersion and place it in a solvent filter for vacuum filtration to obtain a circular graphene film (35mm in diameter and 0.04mm in thickness). After drying in the air overnight, the surface resistance is 300Ωcm -2 .

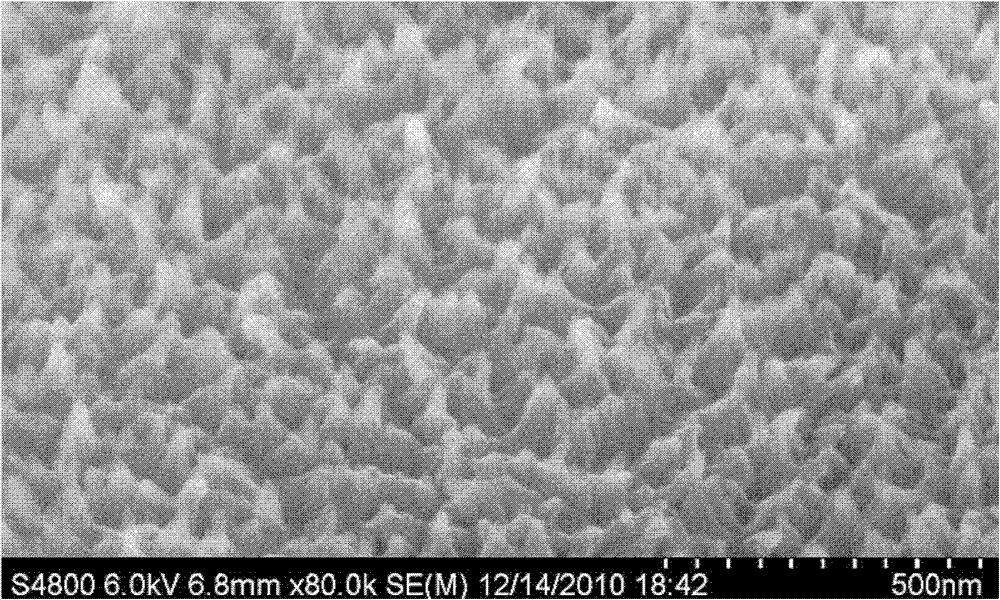

[0093] Electrode preparation method: Add 40 mL of HClO with a concentration of 1 mol / L 4 Add aniline monomer (Sinopharm Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to make the concentration 1mol / L. Put 2 circular graphene films (35×35mm, 0.02mm) with the same shape into the solution, and then add oxidant ammonium persulfate so that its concentration is 0.0067mol / L. The reaction was stirred for 24 hours at a temperature of 0-5°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com