Micro-well based gas sensor array and its making method

A gas sensor and micro-well technology, applied in the direction of electric solid-state devices, semiconductor devices, and processes for producing decorative surface effects, etc., can solve the problem of affecting sensor sensitivity and response recovery time, unfavorable miniaturization and integration, and no invention patents Application and other problems, to achieve the effect of convenient drop coating and film formation, improve sensitivity and response recovery time, and prevent cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

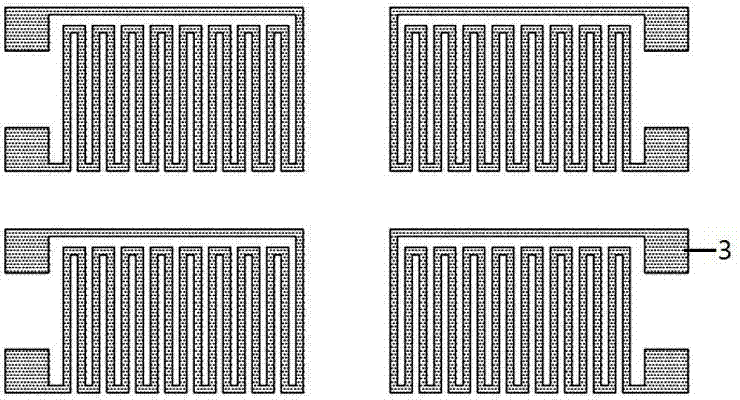

[0038] Such as figure 2 , image 3 and Figure 4 as shown, figure 2 It is a top view of the heating electrode structure of the micro-well gas sensor array provided by the present invention, and each sensitive unit is independently heated; image 3 It is a top view of the interdigitated electrode structure of the micro gas sensor array provided by the present invention, each pair of interdigitated electrodes has an independent output terminal, and the interdigitated electrode array has a common output terminal; Figure 4 It is a structural top view of the micro gas sensor array provided by the present invention, which includes 4 independent micro well sensor units with heating electrodes.

[0039] Such as figure 1 As shown, the technological process steps are as follows:

[0040] (a) Use a 4-inch SOI wafer as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com