Wavefront measuring method based on Hartmann wavefront sensor

A wavefront measurement and sensor technology, applied in the field of optical information measurement, can solve problems such as limitations, complex manufacturing process, and difficulty in realization, and achieve the effects of improving precision, high utilization of light energy, and improving wavefront measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

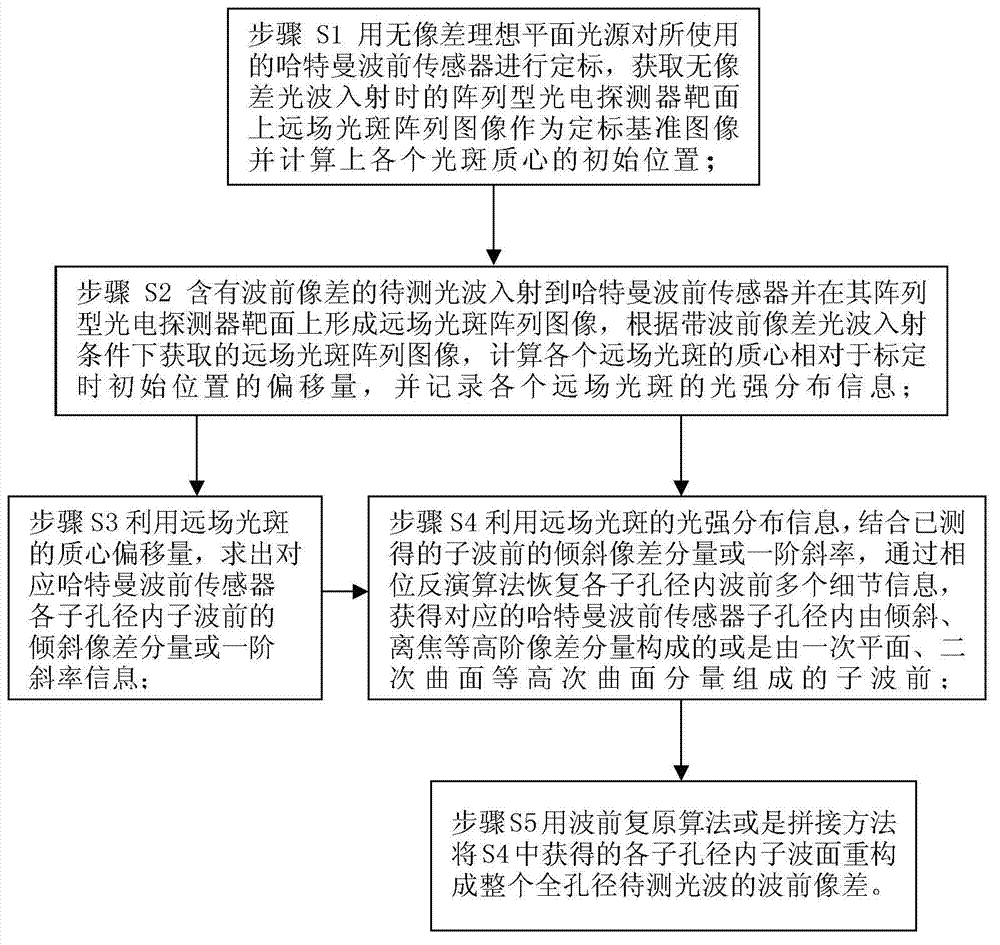

[0017] figure 1 The specific steps of the wavefront measurement method based on the Hartmann wavefront sensor include:

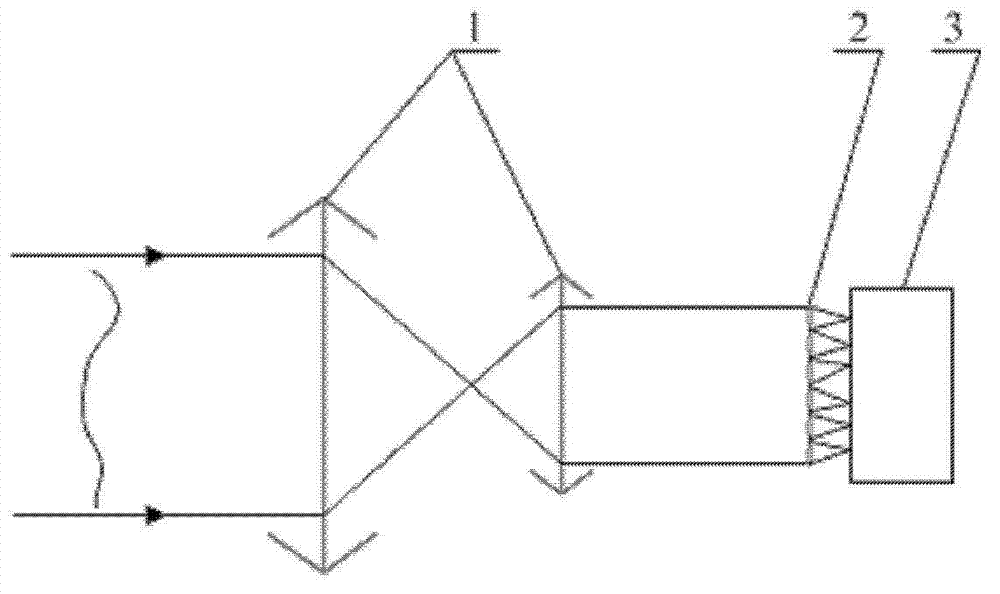

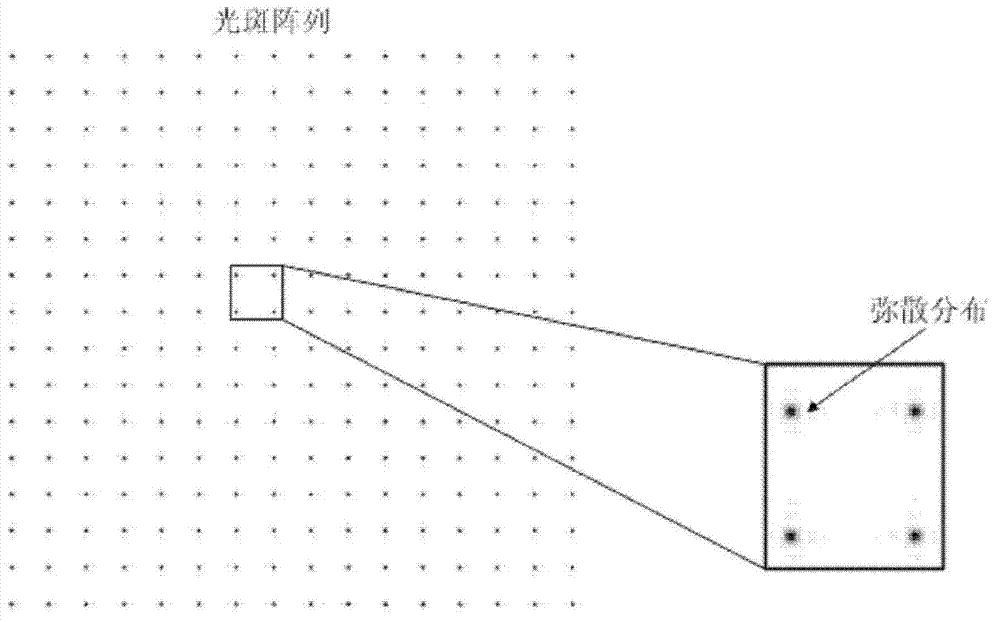

[0018] Step S1: Calibrate the Hartmann wavefront sensor with an aberration-free ideal planar light source to obtain an array photodetector 3( figure 2 Show) the far-field spot array image on the target surface as the calibration reference image, and calculate the initial position of each spot centroid on the calibration reference image;

[0019] Step S2: The light wave to be measured with wavefront aberration is incident on the Hartmann wavefront sensor and forms a far-field spot array image on the target surface of its array photodetector 3, which is obtained under the incident condition of light wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com