Screw retaining ring

A screw buckle and self-tapping screw technology, applied in the direction of connecting components, gaskets, mechanical equipment, etc., can solve the problems of difficult installation of metal plates, easy to fall off, etc., and achieve the effect of improving the pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

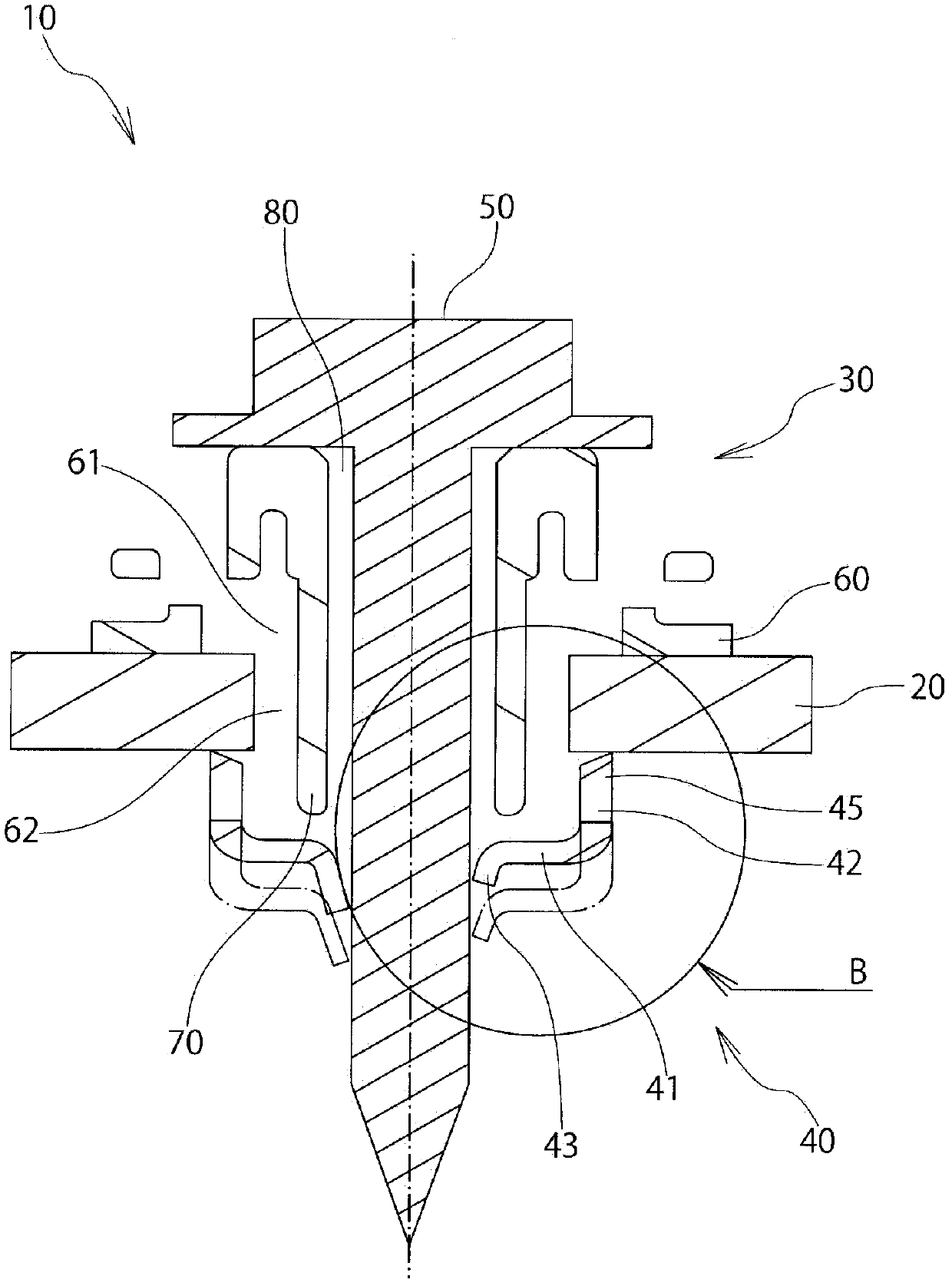

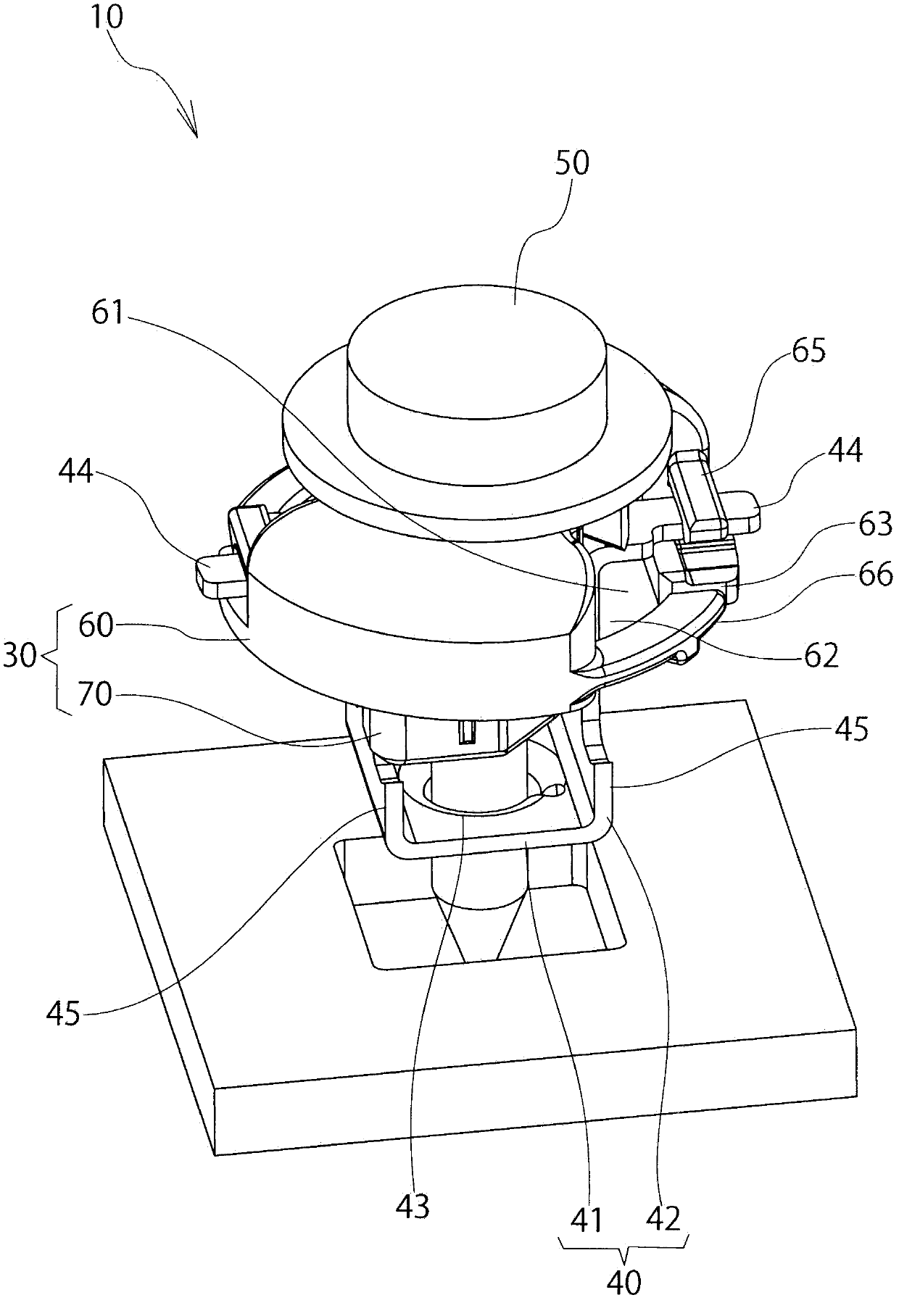

[0129] Among the figure, 10 is a screw clasp, such as figure 2 As shown, it is inserted into the mounting hole 21 of the component to be mounted 20 and mounted.

[0130] The mounted member 20 is a metal panel of an automobile or the like, has electrical conductivity, and has at least one surface thereof painted. like figure 2 As shown, the mounting hole 21 penetrates the front and back of the member 20 to be mounted, and is formed in a substantially square shape.

[0131] In addition, as the mounted member 20 , a metal panel such as an automobile is exemplified, but it is not limited to an automobile or a metal panel. In addition, although the mounting hole 21 is formed in a square shape, it is not limited thereto, and may be formed in other polygonal shapes, circular shapes, elliptical shapes, or the like.

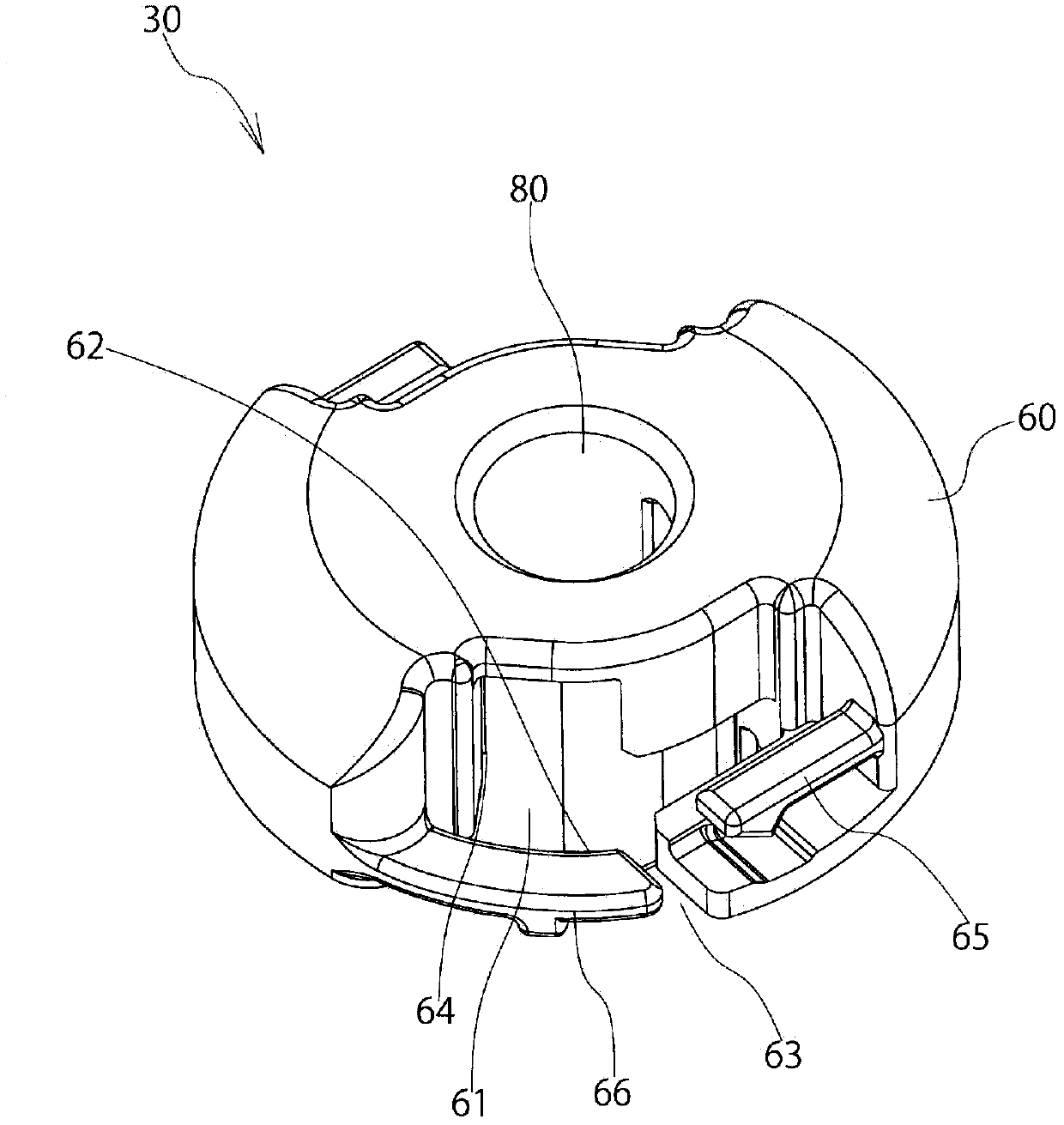

[0132] like Figure 1~6 As shown, the screw buckle 10 is generally composed of the following components.

[0133] In addition, the following (1)-(3) will be mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com