Method for extracting cellulose from tobacco waste based on water-alcohol oxidation process

A technology of tobacco waste and oxidation method, applied in the chemical industry, can solve the problems that hinder the wide application of tobacco cellulose, high cost, low efficiency, etc., and achieve the effect of huge industrial production potential, low cost, and expanded utilization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 100g of dried tobacco waste is pulverized into a particle size of 20 mesh, put into boiling water for 20 minutes, and vacuum filtered to remove moisture to obtain a pretreatment material; 15 times the volume of ethanol solution, the ethanol solution has a volume percentage of 70%, reacted at 100°C for at least 120 minutes, and vacuum filtered to remove water to obtain a filter residue, which was moved into an oven and dried at 105°C until After the mass is constant, it is 19.7g, and the cellulose content in the filter residue is 50.7%.

Embodiment 2

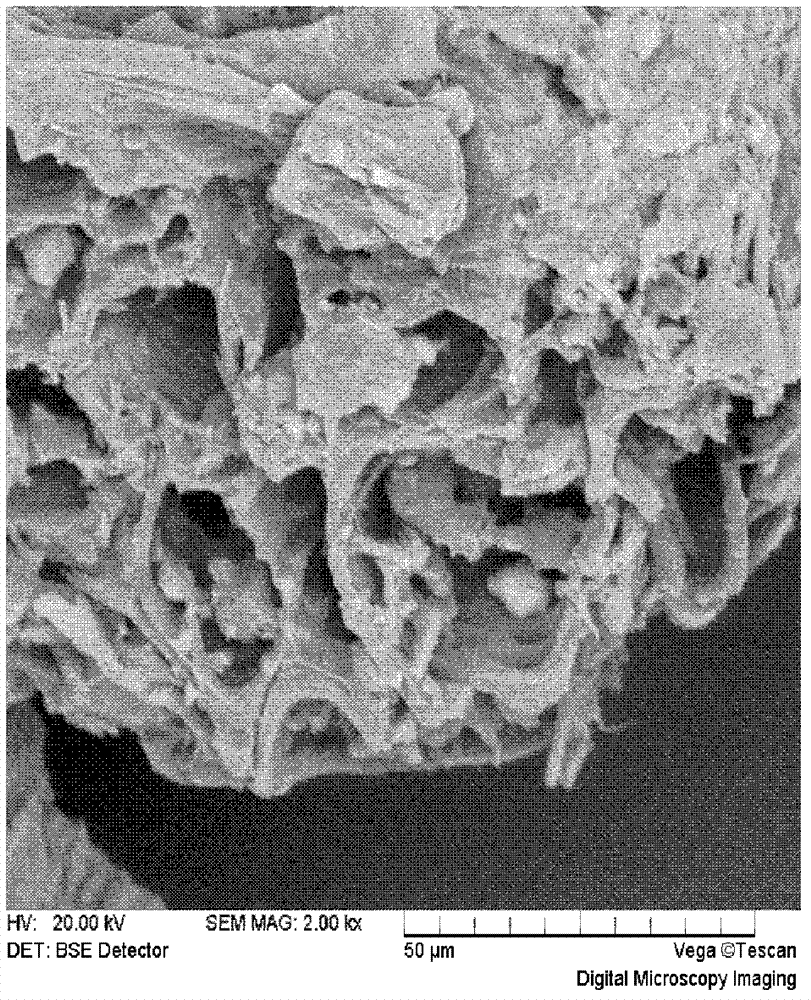

[0031] The SEM image of tobacco waste without any treatment is as follows figure 1 As shown, the surface of the tobacco material is smooth, neat and tightly connected.

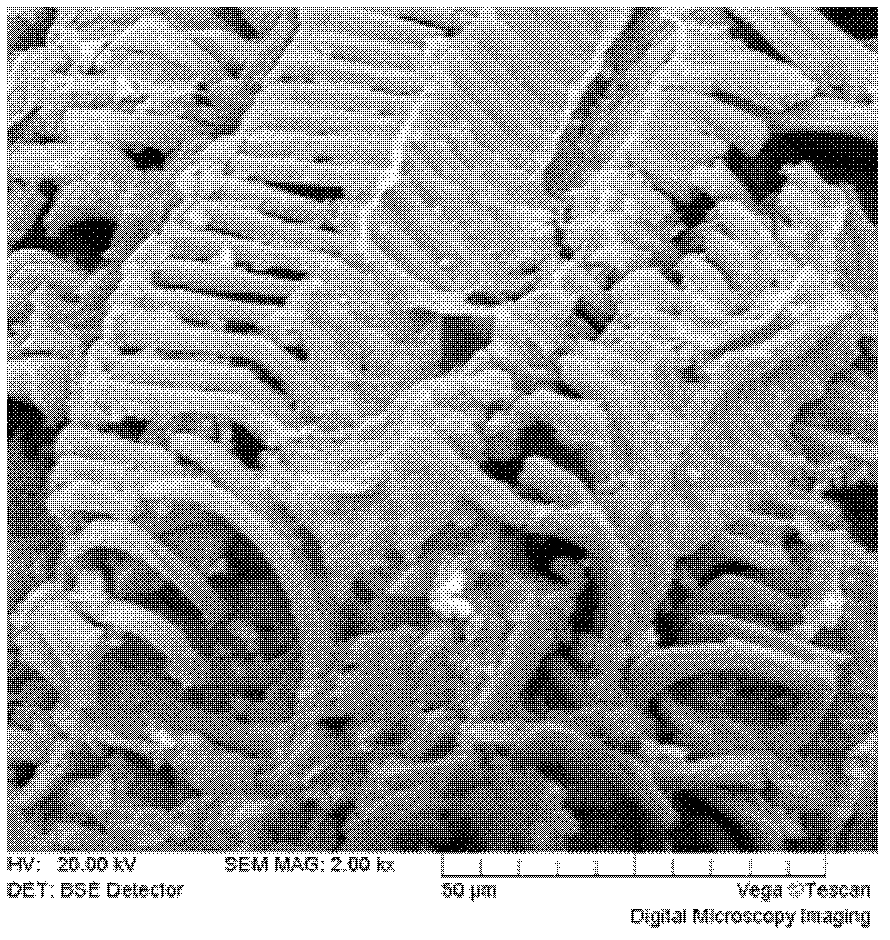

[0032] 100g of dried tobacco waste was pulverized into a particle size of 20 mesh, put into boiling water for 60 minutes, and vacuum filtered to remove moisture to obtain a pretreatment material; 15 times the volume of the ethanol solution, the volume percentage of the ethanol solution is 70%, reacted at 100 ° C for at least 120 minutes, and vacuum filtered to remove moisture to obtain a filter residue, which is crude cellulose, such as figure 2 Breakage of bonds, depressions, voids appear in the tobacco material shown.

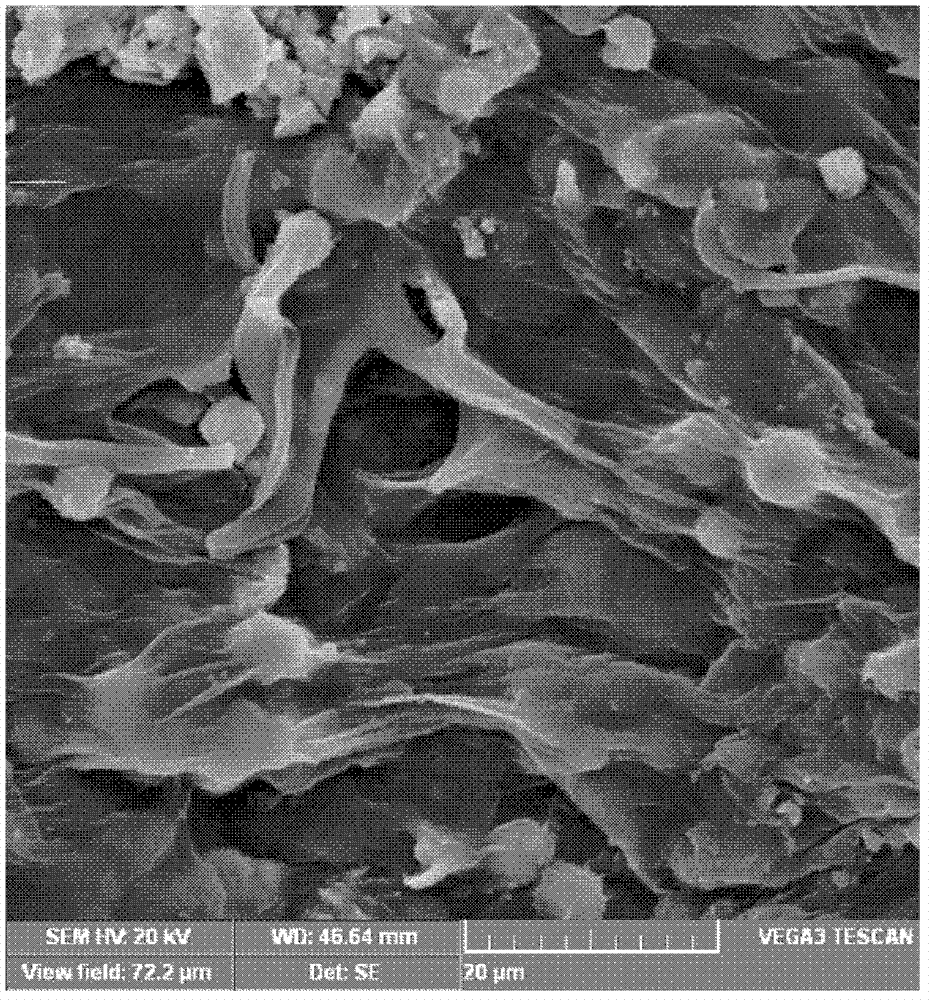

[0033] Put hydrogen peroxide solution in the filter residue, the solid-to-liquid volume ratio of filter residue and hydrogen peroxide solution is 1:10, the reaction time is 60 minutes, the reaction temperature is 30° C., the concentration of hydrogen peroxide solution is 10%, and filter aft...

Embodiment 3

[0035] 100g of dried tobacco waste was pulverized into a particle size of 20 mesh, put into boiling water for 60 minutes, and vacuum filtered to remove moisture to obtain a pretreatment material; 20 times the volume of the ethanol solution, the volume percentage of the ethanol solution is 70%, reacted at 100°C for at least 120 minutes, and vacuum filtered to remove water to obtain a filter residue, which is crude cellulose.

[0036] Put into hydrogen peroxide solution in described filter residue, the solid-liquid volume ratio of filter residue and hydrogen peroxide solution 1: 5, reaction time 60 minutes, 30 ℃ of reaction temperatures, the volume percent concentration of hydrogen peroxide solution 8%, reaction Filtration is carried out after completion, and the obtained filter residue is moved into an oven, and dried at 105° C. until the mass is constant to 20.8 g, and the cellulose content of the filter residue is 63.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com