Liquid optical clear adhesive for liquid crystal display touch screen and preparation method thereof

An optically transparent adhesive, touch screen technology, applied in the direction of adhesives, rubber-derived adhesives, adhesive types, etc., can solve the problems of low transmittance, adhesive discoloration, yellowing, etc., to achieve good fluidity, easy adhesive layer thickness , Adhesive strength and anti-yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

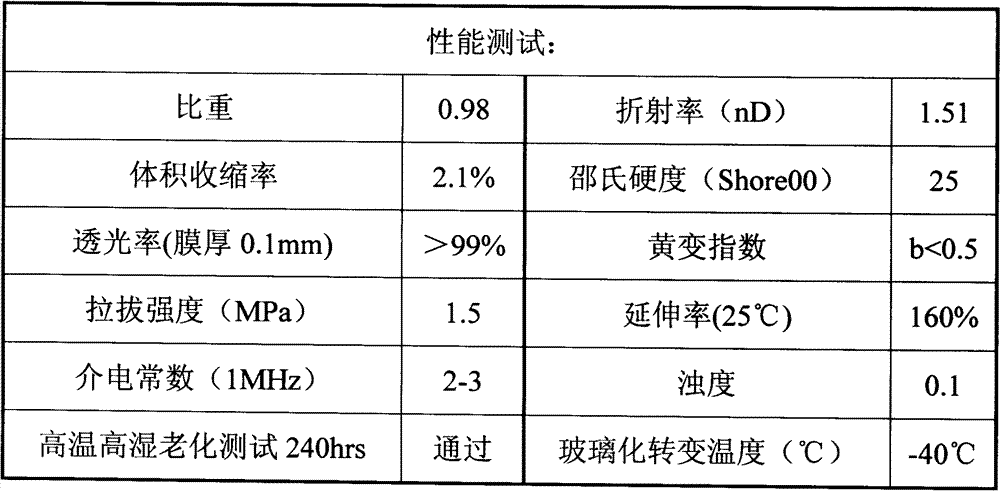

Examples

Embodiment 1

[0033] Weigh 55g of maleic anhydrided isoprene telomer with molecular weight between 12000~18000, 30g of liquid butadiene rubber, 4g of liquid polybutadiene and its derivatives, 4g of cyanide terpene resin, formazan Acrylic acid-2-hydroxypropyl ester 4g (Germany Connect Chemical Company); 4,6-bis(dodecylthiomethyl)-O-cresol 0.2g (Germany Bayer (Bayer) company); Japan Fuji Chemical 1020 ( Latent modified amine curing agent) 0.2g was stirred at 60°C for 3 hours to make it evenly mixed.

[0034] Lower the temperature to 40°C, add 1.2 g of photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours , until the materials are completely miscible.

[0035] After checking that the viscosity is between 600-800cps, the material is filtered through a 1800-mesh stainless steel screen, vacuumed and kept at a vacuum degree of -0.1MPa for 60 minutes, and the air bubbles in the mixt...

Embodiment 2

[0037] Weigh 50 g of maleic anhydrided isoprene telomer with a molecular weight of 12,000 to 18,000, 5 g of a maleic anhydrided isoprene telomer with a molecular weight of 32,000 to 38,000, and 30 g of liquid butadiene rubber Liquid polybutadiene and derivatives thereof 4g; Cyanide terpene resin 4g; Methacrylate-2-hydroxypropyl 4g (Germany Connect chemical company); 4,6-bis(dodecylthiomethyl)- O-cresol 0.2 g (Bayer, Germany); Japan Fuji Chemical 10200.2 g (latent modified amine curing agent) were stirred at 60° C. for 3 hours to make them evenly mixed.

[0038] Lower the temperature to 40°C, add 1.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours until the material Completely miscible.

[0039] After checking that the viscosity is between 1200 and 1600cps, the material is filtered through a 1800-mesh stainless steel sieve, vacuumed and maintained at a vacuum degree ...

Embodiment 3

[0041] Weigh 45 g of maleic anhydrided isoprene telomer with a molecular weight of 12,000 to 18,000, 10 g of a maleic anhydrided isoprene telomer with a molecular weight of 32,000 to 38,000, and 30 g of liquid butadiene rubber Liquid polybutadiene and derivatives thereof 4g; Cyanide terpene resin 4g; Methacrylate-2-hydroxypropyl 4g (Germany Connect chemical company); 4,6-bis(dodecylthiomethyl)- 0.2 g of O-cresol (Bayer, Germany); 0.2 g of Fuji Chemical 1020 (latent modified amine curing agent) were stirred at 60° C. for 3 hours to make them evenly mixed.

[0042] Lower the temperature to 40°C, add 1.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours until the material Completely miscible.

[0043] After checking that the viscosity is between 1800 and 2200cps, the material is filtered through a 1800-mesh stainless steel sieve, vacuumed and maintained at a vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com