Liquid optical clear adhesive for liquid crystal display touch screen and preparation method thereof

A technology of optical transparent glue and touch screen, applied in the direction of adhesive, rubber derivative glue, adhesive type, etc., can solve the problems of glue discoloration, yellowing, low transmittance, etc., and achieve easy glue layer thickness, adhesion strength and yellow resistance Change, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

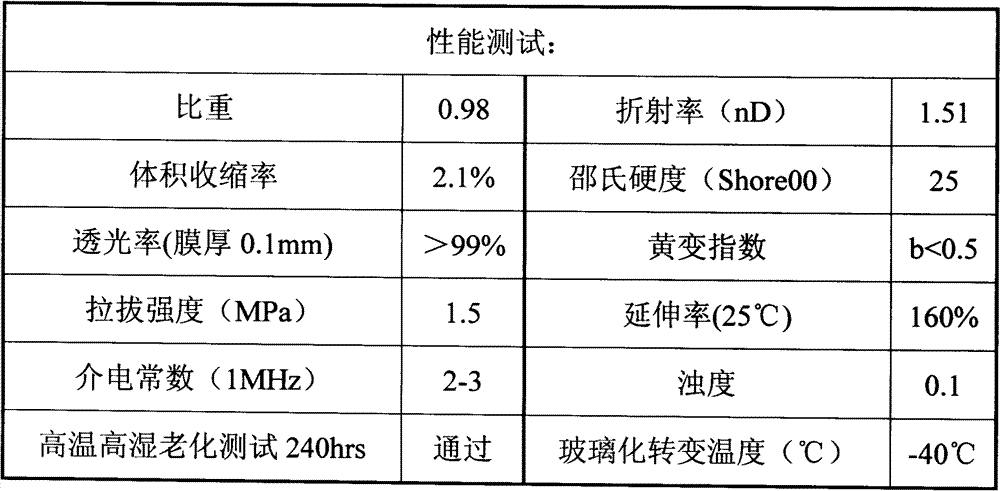

Examples

Embodiment 1

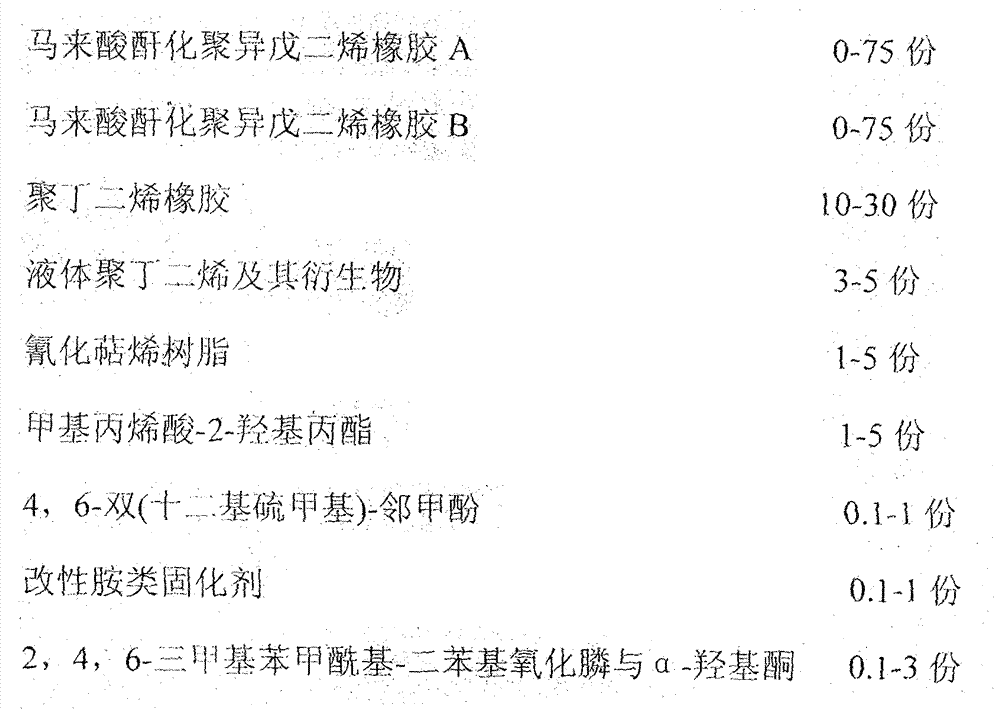

[0033] Weigh 55g of maleic anhydrided isoprene telomer with molecular weight between 12000~18000, 30g of liquid butadiene rubber, 4g of liquid polybutadiene and its derivatives, 4g of cyanide terpene resin, formazan Acrylic acid-2-hydroxypropyl ester 4g (Germany Connect Chemical Company); 4,6-bis(dodecylthiomethyl)-O-cresol 0.2g (Germany Bayer (Bayer) company); Japan Fuji Chemical 1020 ( Latent modified amine curing agent) 0.2g was stirred at 60°C for 3 hours to make it evenly mixed.

[0034] Lower the temperature to 40°C, add 1.2 g of photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours , until the materials are completely miscible.

[0035] After checking that the viscosity is between 600-800cps, the material is filtered through a 1800-mesh stainless steel screen, vacuumed and kept at a vacuum degree of -0.1MPa for 60 minutes, and the air bubbles in the mixt...

Embodiment 2

[0037] Weigh 50 g of maleic anhydrided isoprene telomer with a molecular weight of 12,000 to 18,000, 5 g of a maleic anhydrided isoprene telomer with a molecular weight of 32,000 to 38,000, and 30 g of liquid butadiene rubber Liquid polybutadiene and derivatives thereof 4g; Cyanide terpene resin 4g; Methacrylate-2-hydroxypropyl 4g (Germany Connect chemical company); 4,6-bis(dodecylthiomethyl)- O-cresol 0.2 g (Bayer, Germany); Japan Fuji Chemical 10200.2 g (latent modified amine curing agent) were stirred at 60° C. for 3 hours to make them evenly mixed.

[0038] Lower the temperature to 40°C, add 1.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours until the material Completely miscible.

[0039] After checking that the viscosity is between 1200 and 1600cps, the material is filtered through a 1800-mesh stainless steel sieve, vacuumed and maintained at a vacuum degree ...

Embodiment 3

[0041] Weigh 45 g of maleic anhydrided isoprene telomer with a molecular weight of 12,000 to 18,000, 10 g of a maleic anhydrided isoprene telomer with a molecular weight of 32,000 to 38,000, and 30 g of liquid butadiene rubber Liquid polybutadiene and derivatives thereof 4g; Cyanide terpene resin 4g; Methacrylate-2-hydroxypropyl 4g (Germany Connect chemical company); 4,6-bis(dodecylthiomethyl)- 0.2 g of O-cresol (Bayer, Germany); 0.2 g of Fuji Chemical 1020 (latent modified amine curing agent) were stirred at 60° C. for 3 hours to make them evenly mixed.

[0042] Lower the temperature to 40°C, add 1.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 1.4 g of α-hydroxy ketone to the mixture obtained in the above steps, and continue stirring for 2 hours until the material Completely miscible.

[0043] After checking that the viscosity is between 1800 and 2200cps, the material is filtered through a 1800-mesh stainless steel sieve, vacuumed and maintained at a vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com