Composition for water-based glass bottle baking varnish

A composition, water-based technology, applied in the direction of coating, etc., can solve the problems of overall performance improvement, relatively large decrease in paint film drying speed, no further improvement in alcohol resistance, etc., and achieve the best performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

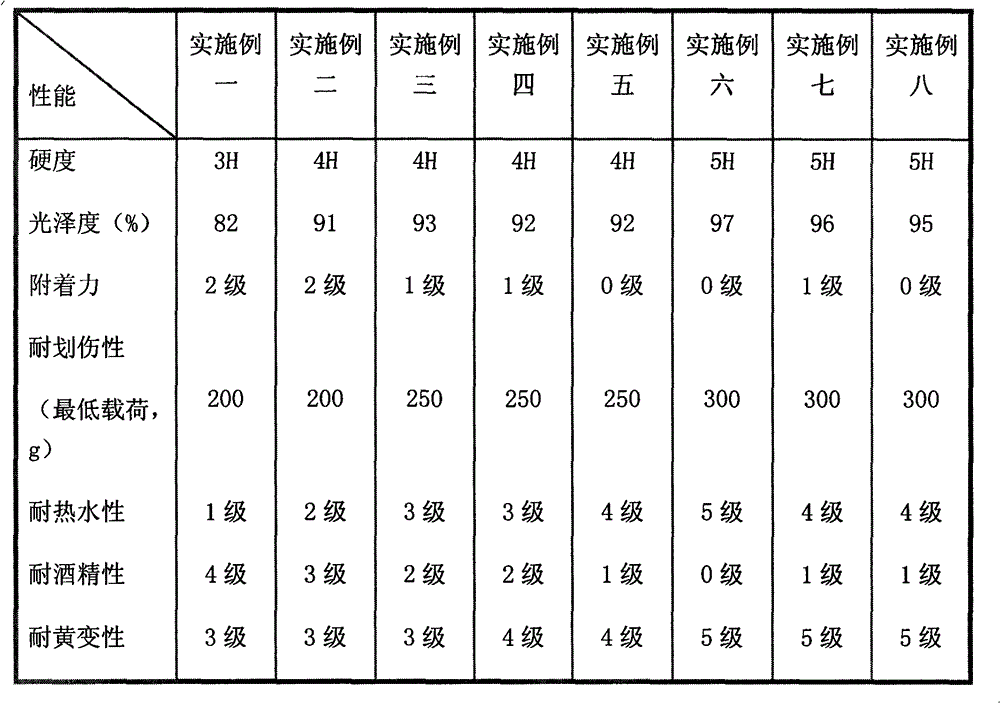

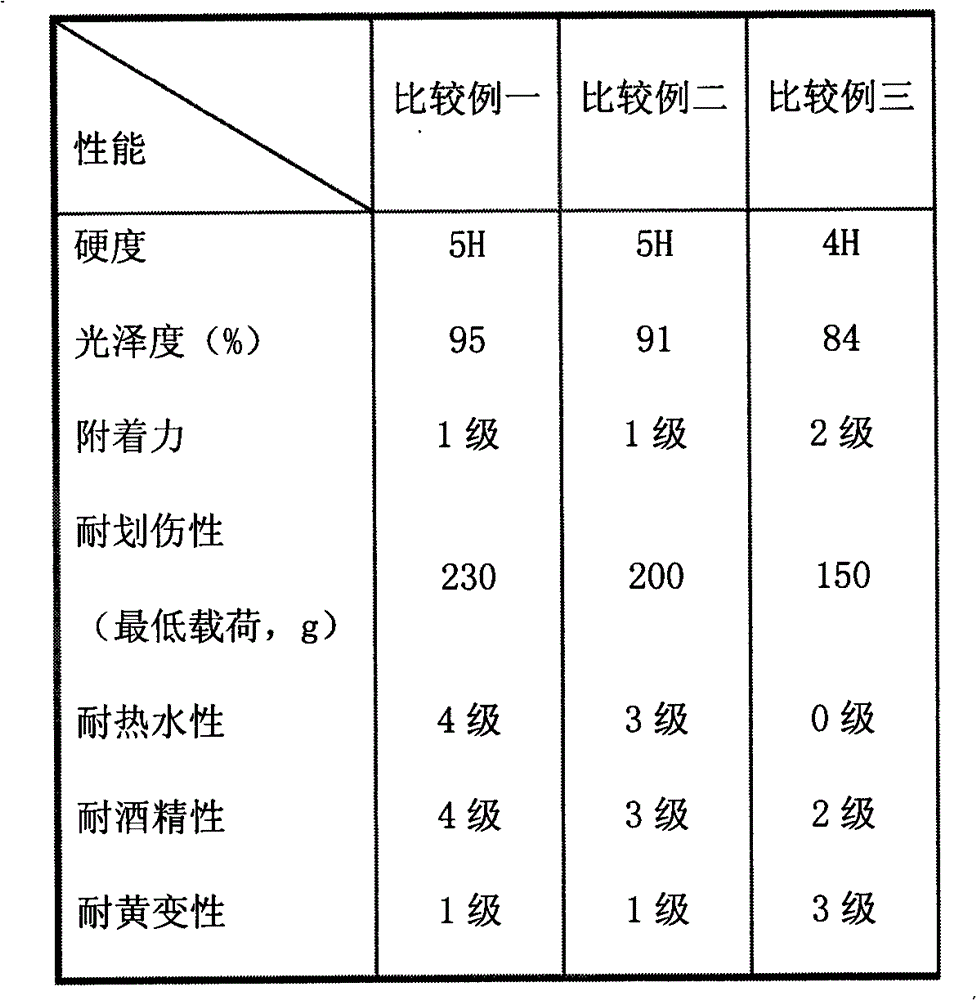

Examples

Embodiment 1

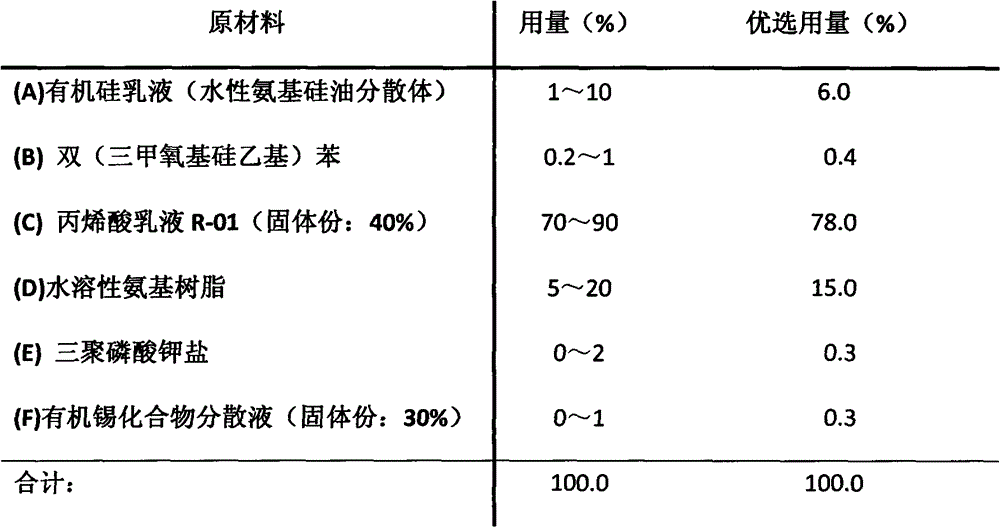

[0013] 1. Synthetic acrylic resin formula table (code: R-01):

[0014] Formula

Dosage

Preferred dosage

A. Nuclear monomer:

0~60

23.8

90~120

104.3

Acrylic

1.5~3

2.4

B. Shell monomer:

60~105

89.4

[0015] Methyl methacrylate

90~105

95.5

Acrylic

16~35

25.9

C. Base material:

Sodium nonylphenol polyoxyethylene ether sulfate (AES)

3.6~4.8

4.2

Octylphenol polyoxyethylene vinyl ether (TX-10)

1.8~2.4

2.2

Dodecyl mercaptan (molecular weight regulator)

0~1.0

0.5

Water

300~360

327.8

D. Initial initiator:

Sodium peroxosulfate

0.3~0.6

0.5

Water

29.7~59.4

39.5

E. Initiator aqueous solution (for dripping):

Sodium peroxosulfate

0.7~0.9

0.8

Water

69.3~89.1

79.2

F. PH value regulator:

0.3~0.7

0.5

Water

2.7~6.3

4.5

G. Neutralizer:

Ammonia (28%)

6.4~15.2

10.3

Water

17.8~44.7

29.7

[0016] Operation method:

[0017] (1) Pu...

Embodiment 2

[0043] The difference from Example 1 is that water-soluble polyamide resin is added to the synthetic formula, which reduces the amount of OP-10 and AES surfactants.

[0044] 1. Synthetic acrylic resin formula table (code: R-02):

[0045] Formula

Dosage

Preferred dosage

A. Nuclear monomer:

0~60

23.8

90~120

104.3

Acrylic

1.5~3

2.4

B. Shell monomer:

Butyl Acrylate

60~105

89.4

Methyl methacrylate

90~105

95.5

Acrylic

16~35

25.9

C. Base material:

Sodium nonylphenol polyoxyethylene ether sulfate (AES)

2.0~4.0

2.5

Polyoxyethylene octylphenol ether (TX-10)

0~1.0

0.3

Water-soluble polyamide resin

5~10

8.0

Dodecyl mercaptan

0~1.0

0.5

Water

300~360

327.8

D. Initial initiator:

Sodium peroxosulfate

0.3~0.6

0.5

Water

29.7~59.4

39.5

E. Initiator aqueous solution (for dripping):

Sodium peroxosulfate

0.7~0.9

0.8

Water

69.3~89.1

79.2

F. PH value regulator:

Embodiment 3

[0054] The difference from Example 2 is that acrylonitrile is added to the synthetic formula

[0055] 1. Synthetic acrylic resin formula table (code: R-03):

[0056] Formula

Dosage

Preferred dosage

A. Nuclear monomer:

[0057] Butyl Acrylate

0~60

23.8

Methyl methacrylate

0~120

68.6

0~90

35.7

Acrylic

1.5~3

2.4

B. Shell monomer:

Butyl Acrylate

60~105

89.4

Methyl methacrylate

11~105

62.8

0~79

32.7

Acrylic

16~35

25.9

C. Base material:

Sodium nonylphenol polyoxyethylene ether sulfate (AES)

2.0~4.0

2.5

Octylphenol polyoxyethylene vinyl ether (TX-10)

0~1.0

0.3

Water-soluble polyamide resin

5~10

8.0

Dodecyl mercaptan

0~1.0

0.5

Water

300~360

327.8

D. Initial initiator:

Sodium peroxosulfate

0.3~0.6

0.5

Water

29.7~59.4

39.5

E. Dropping initiator:

Sodium peroxosulfate

0.7~0.9

0.8

Water

69.3~89.1

79.2

F. PH value regulator:

0.3~0.7

0.5

Wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com