Cotton knitted fabric scouring, bleaching, dyeing and soaping whole-process low temperature dyeing and finishing processing technology

A cotton knitted fabric, low temperature dyeing and finishing technology, applied in the direction of dyeing method, bleached products, plant fibers, etc., can solve the problem of difficult to obtain high temperature processing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Process flow: low temperature scouring and bleaching → low temperature washing → low temperature dyeing → low temperature soaping

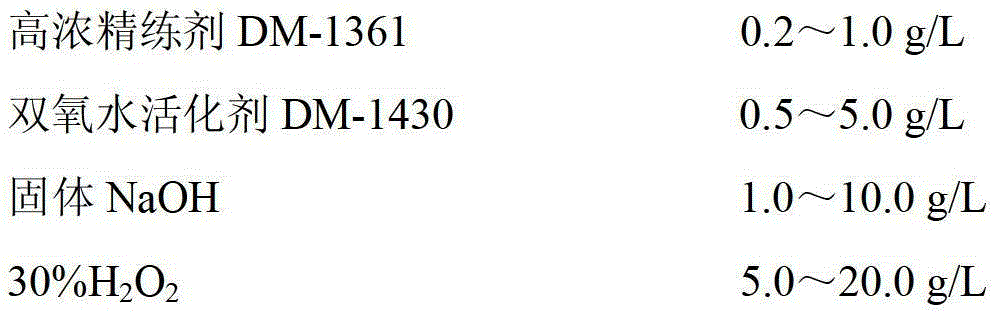

[0044] Low temperature bleaching:

[0045]

[0046] Liquor ratio 1:10, 30°C into the cloth, 2°C / min to 40°C, keep warm for 120min, drain, wash at 40°C for 10min, then wash in cold water.

[0047] Low temperature dyeing:

[0048] Reactive Red 3BS 2.0% (O.W.F)

[0049] Na 2 SO 4 50.0g / L

[0050] Na 2 CO 3 20.0g / L

[0051] Liquor ratio 1:10, 30 ℃ into the cloth, 2 ℃ / min to 60 ℃, heat preservation 60min, drain, cold water washing, neutralization, soaping.

[0052] Low temperature soaping:

[0053] Low temperature soaping agent DM-1542 2.0g / L

[0054] Liquor ratio 1:10, 30 ℃ into the cloth, 2 ℃ / min to 40 ℃, heat preservation 30min, drain, cold water wash.

Embodiment 2

[0056] Process flow: low temperature scouring and bleaching → low temperature washing → low temperature dyeing → low temperature soaping

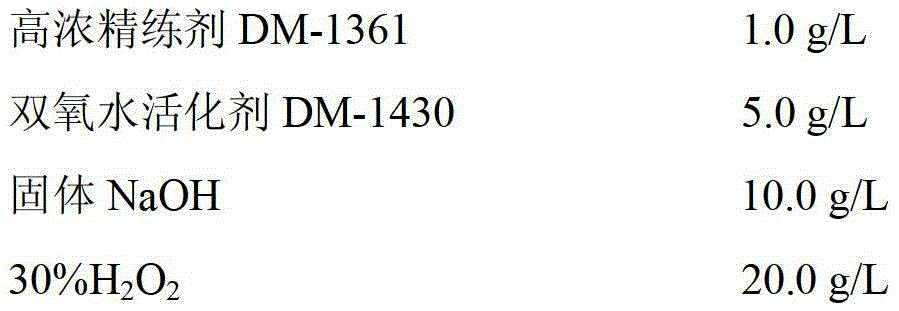

[0057] Low temperature bleaching:

[0058]

[0059]

[0060] Liquor ratio 1:10, 30°C into the cloth, 2°C / min to 70°C, keep warm for 30 minutes, drain, wash at 70°C for 10 minutes, and wash in cold water.

[0061] Low temperature dyeing:

[0062] Reactive Yellow 3RS 1.5% (O.W.F)

[0063] Na 2 SO 4 50.0g / L

[0064] Na 2 CO 3 20.0g / L

[0065] Liquor ratio 1:10, 30 ℃ into the cloth, 2 ℃ / min to 60 ℃, heat preservation 60min, drain, cold water washing, neutralization, soaping.

[0066] Low temperature soaping:

[0067] Low temperature soaping agent DM-1542 0.2g / L

[0068] Liquor ratio 1:10, 30°C into the cloth, 2°C / min to 70°C, keep warm for 10min, drain, wash with cold water.

Embodiment 3

[0070] Process flow: Enzyme scouring→low temperature scouring and bleaching→low temperature washing water→low temperature dyeing→low temperature soaping

[0071] Low temperature bleaching:

[0072] A>Enzyme refining

[0073] High concentration scouring agent DM-1361 0.2g / L

[0074] Scouring enzyme DM-8654 0.3g / L

[0075] Liquor ratio 1:10, put into cloth at 30°C, heat up to 70°C at 2°C / min, keep warm for 30min, turn to low temperature for scouring and bleaching.

[0076] B>Low temperature bleaching

[0077]

[0078] Liquor ratio 1:10, 30°C into the cloth, 2°C / min to 70°C, keep warm for 30 minutes, drain, wash at 70°C for 10 minutes, and wash in cold water.

[0079] Low temperature dyeing:

[0080] Active Cuilan KN-G 1.6% (O.W.F)

[0081] Na 2 SO 4 50.0g / L

[0082] Na 2 CO 3 20.0g / L

[0083] Liquor ratio 1:10, 30 ℃ into the cloth, 2 ℃ / min to 60 ℃, heat preservation 60min, drain, cold water washing, neutralization, soaping.

[0084] Low temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com