Preparation method of double-metal cyanidation complex catalyst

A double metal cyanation and complex technology, which is applied in the field of preparing double metal cyanide complex catalysts, can solve the problems of cumbersome process, high cost, easy introduction of unstable factors and the like, and achieves simplified preparation process and reduced cost , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A double metal cyanide complex catalyst is prepared by the following steps:

[0035] (1) 0.01mol potassium cobaltcyanide is dissolved in 50mL water to obtain potassium cobaltcyanide solution, and 0.037mol zinc chloride is dissolved in the mixed solution of 150mL water and 75mL tert-butanol to obtain zinc chloride solution; under vigorous stirring , the potassium cobalt cyanide solution was slowly dropped into the zinc chloride solution, and the dripping was completed in 30 minutes, and then 0.03mol 18-crown-6 was added, and the vigorous stirring was continued for 5 hours;

[0036] (2) Centrifuge the precipitate, grind the resulting precipitate in a ball mill and liquefy the slurry with a mixture of 125mL tert-butanol and 125mL water, stir and keep it warm for 1h; 1h;

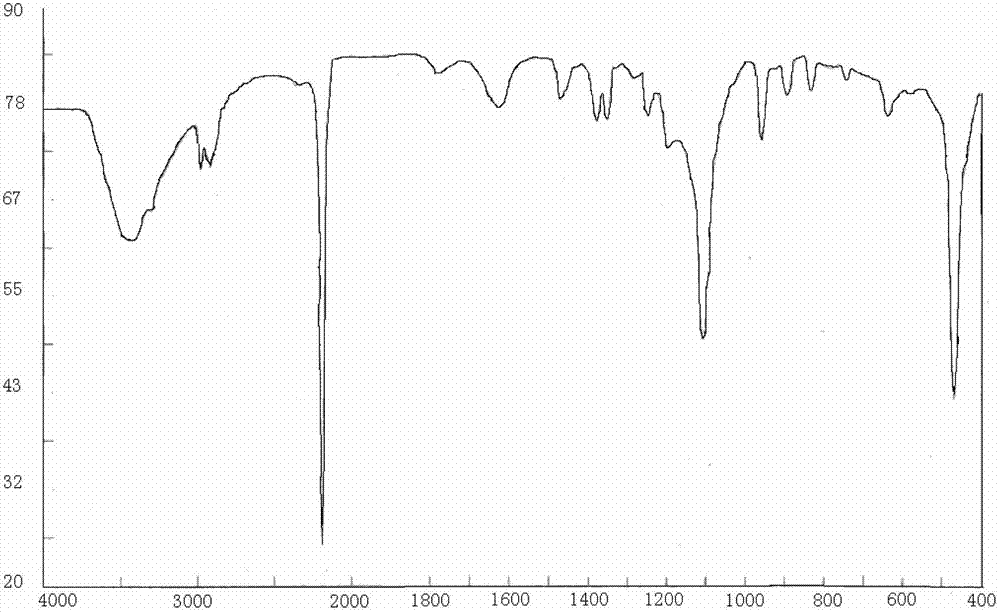

[0037] (3) Centrifuge and precipitate the slurry with pure tert-butanol and stir for 1 h, centrifuge and separate the precipitate; dry the precipitate in a vacuum oven at 45° C. for 15 h to obtain a whit...

Embodiment 2

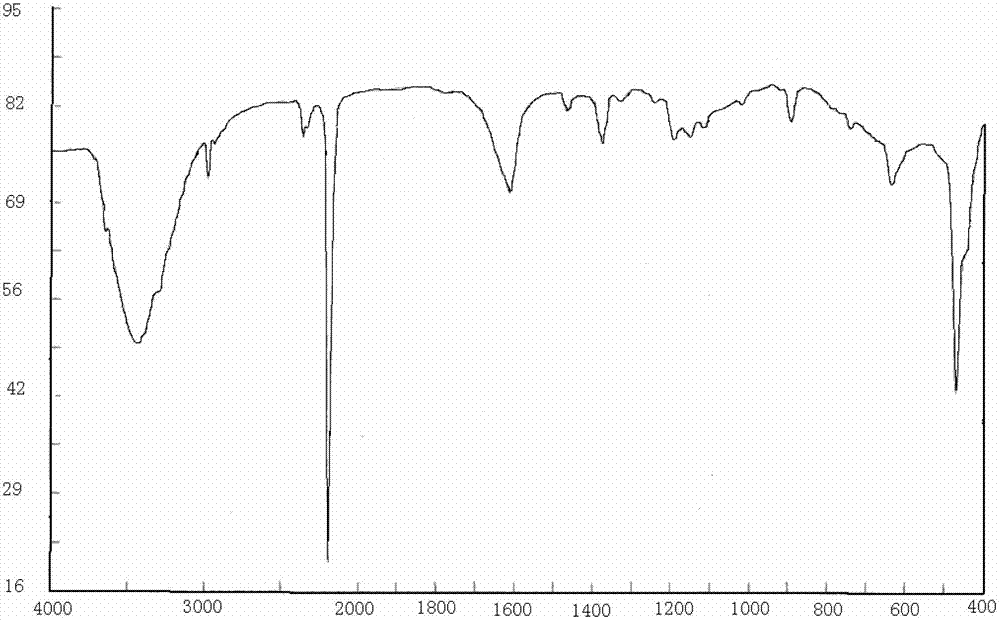

[0041] A kind of preparation method of double metal cyanide complex catalyst, its raw material and operation are the same as embodiment 1, just do not add 18-crown ether-6 from beginning to end. By elemental analysis (see Table 2) and infrared spectroscopy (see figure 2 ) determined that the double metal cyanide complex catalyst obtained at last consists of Zn 3 [Co(CN) 6 ] 2 1.6ZnCl 2 1.1t-BuOH 1.8H 2 O.

[0042] The elemental analysis result of the double metal cyanide complex catalyst that table 2 embodiment 2 obtains

[0043] Element mass fraction (%)

Embodiment 3

[0045] Under nitrogen protection, 7 mg of the catalyst obtained in Example 1 and 24.9 g of propylene oxide were added to a fully dried 130 ml autoclave, filled with 18 g of carbon dioxide, and the temperature was raised to 80°C. React 15h under stirring condition and emit product, vacuum removes unreacted propylene oxide, obtains polycarbonate polyalcohol 28.7g, test result shows that carbonate bond content is 44% in the product, and by-product (cyclic carbonate) content is 3%. The catalytic efficiency is about 4100g / g.

[0046] Under nitrogen protection, 7 mg of the catalyst obtained in Example 2 was added to a fully dried 130 ml autoclave, and then 24.9 g of propylene oxide was added, 18 g of carbon dioxide was charged, and the temperature was raised to 80° C. React 15h under stirring condition and emit product, vacuum removes unreacted propylene oxide, obtains the very high polycarbonate polyol 26.8g of viscosity, test result shows that carbonate bond content is 35% in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com