Method for preparing industrial-grade and food-grade phosphoric acid by emulsification, extraction and purification wet method

A wet-process phosphoric acid, industrial-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high price of barium carbonate/barium hydroxide, small barium sulfate particles, increased product cost, etc., to achieve saving The effect of removing the filtration and separation process, shortening the production cycle, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of technical grade phosphoric acid

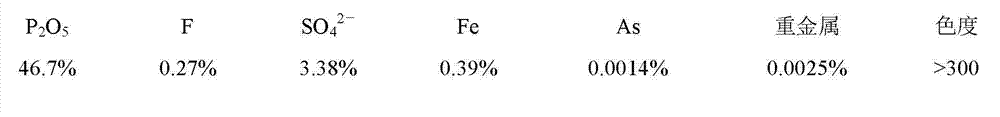

[0028] In the present embodiment, the composition of used raw material wet process phosphoric acid is as follows:

[0029]

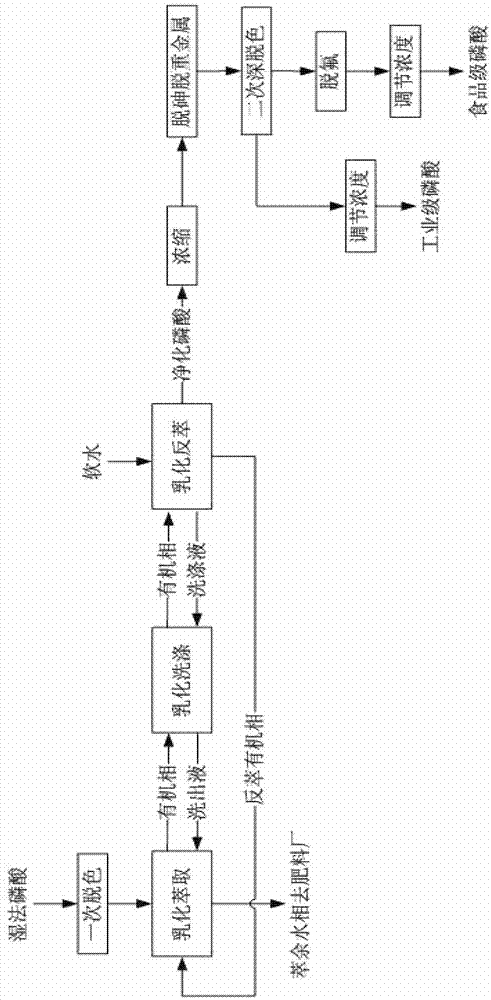

[0030] Process steps such as figure 1 As shown, the steps are primary decolorization, emulsification extraction, emulsification washing, emulsification back extraction, arsenic removal and heavy metal removal, secondary decolorization, and concentration adjustment.

[0031] (1) One decolorization

[0032] A decolorization operation was carried out in a decolorization tank, the decolorizing agent was ozone, the addition was 0.3% of the phosphoric acid quality, the reaction temperature was 50 ° C, and the reaction time was 40 min.

[0033] (2) Emulsifying extraction

[0034] The emulsification extraction process extracts the phosphoric acid after the primary decolorization, using the mixture of tributyl phosphate and kerosene as the extractant, the volume percentage of kerosene is 40%...

Embodiment 2

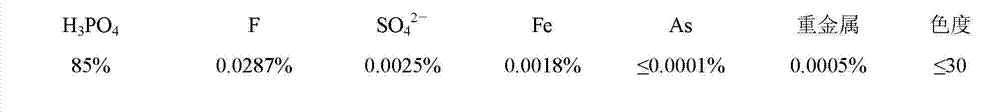

[0049] Example 2: Preparation of food grade phosphoric acid

[0050] In the present embodiment, the composition of used raw material wet process phosphoric acid is as follows:

[0051]

[0052] Process steps such as figure 1 As shown, the sequence is primary decolorization, emulsification extraction, emulsification washing, emulsification stripping, concentration, arsenic and heavy metal removal, secondary deep decolorization, defluorination and concentration adjustment.

[0053] (1) One decolorization

[0054] The primary decolorization process was carried out in a primary decolorization tank, the decolorizing agent was ozone, the addition amount was 3% of the mass of phosphoric acid, the reaction temperature was 60 °C, and the reaction time was 10 min.

[0055] (2) Emulsifying extraction

[0056] The emulsification extraction process extracts the phosphoric acid after the primary decolorization, using the mixture of tributyl phosphate and kerosene as the extraction age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com