Automatic magnetic grinding machine

A magnetic grinding, fully automatic technology, used in grinding machines, machine tools suitable for grinding workpiece edges, and surface polishing machine tools, etc., can solve problems such as reduced production efficiency, low grinding efficiency, and inability to streamline production, and improve processing efficiency. , The effect of guaranteeing the processing quality and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

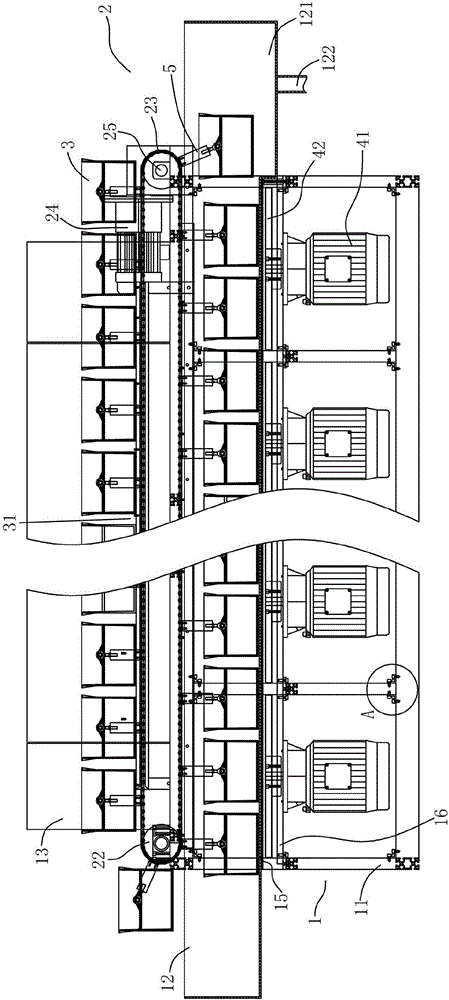

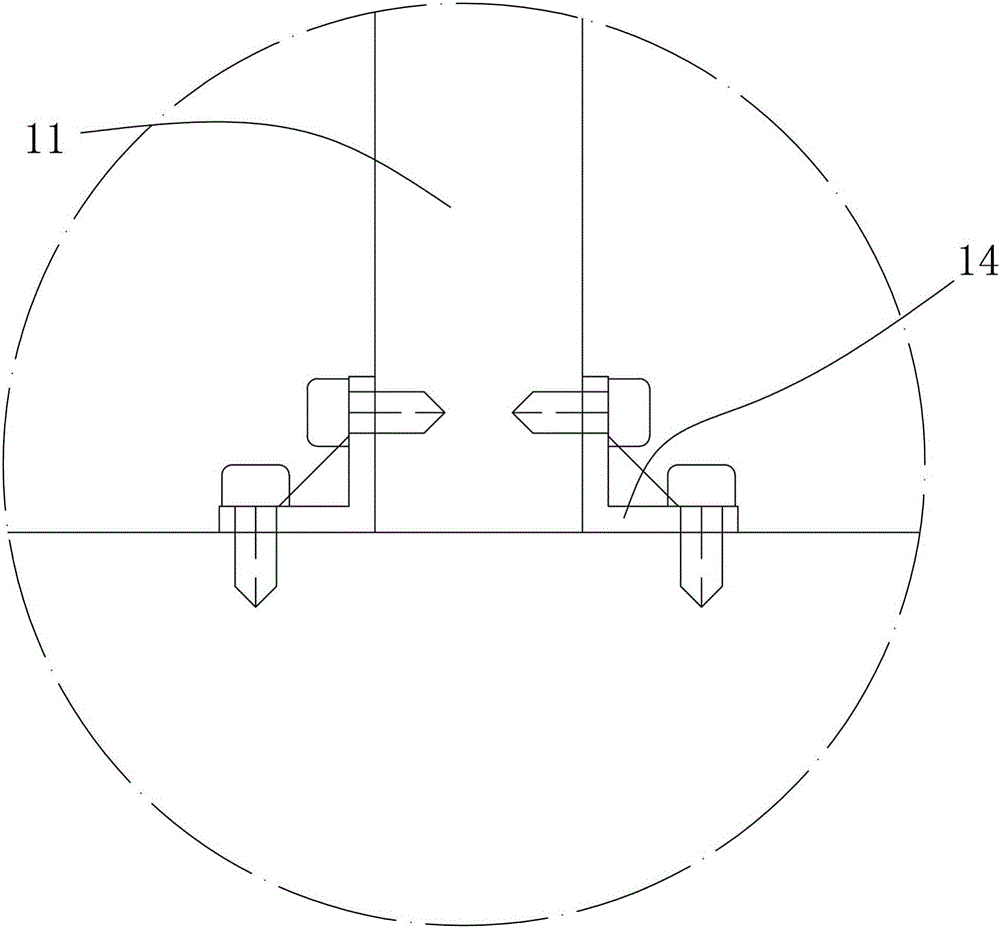

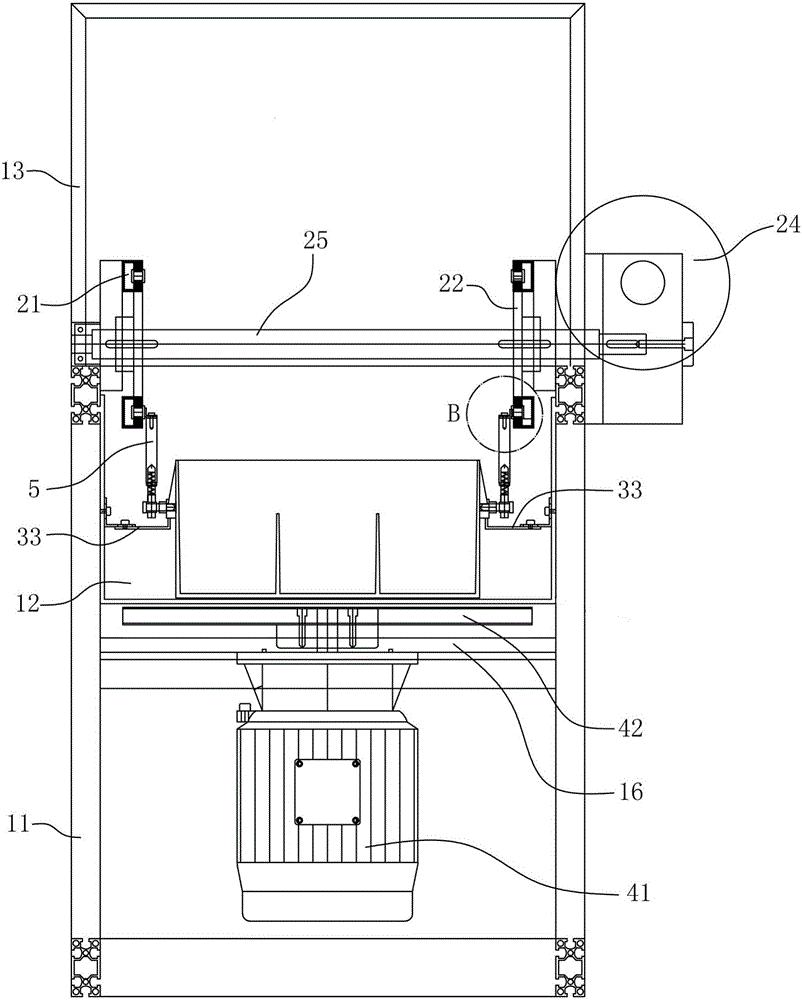

[0025] Such as Figure 1-8 As shown, the present invention relates to a fully automatic magnetic grinding machine, which includes a body 1, a transmission mechanism 2 for cyclic transmission, a plurality of grinding containers 3 for containing materials, and a magnetic force generating device 4 for grinding. The body 1 includes The frame 11, the water tank 12 installed on the frame 11, the protective plate installed on the frame 11 and the machine cover 13 arranged on the upper end of the frame 11, the frame 11 is made of a plurality of aluminum profiles through right-angled connectors 14 are connected end to end and fixed with screws. The aluminum profiles forming the frame 11 can be 4×4 and 4×8 (in cm) thickened general standard aluminum profiles, and the two sides and the top of the frame 11 are made of iron. The plate is used as a protective pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com