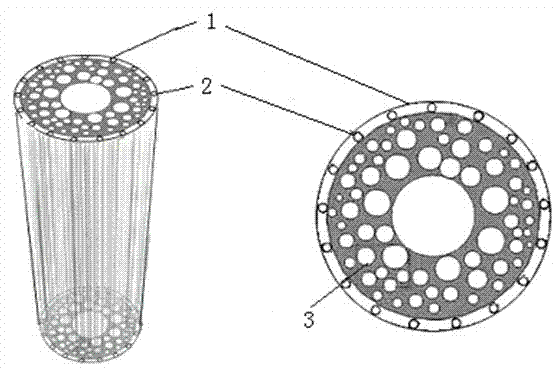

Construction and preparation of three-dimensional bionic electropolarized gradient pore nerve conduit

A nerve conduit and bionic electricity technology are applied in the field of construction and preparation of nerve conduits, and achieve the effects of simple preparation method, solving directional adhesion and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

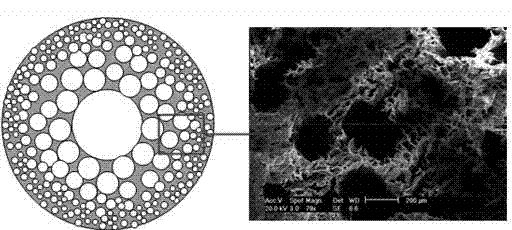

[0031] The preparation steps of the three-dimensional bionic electric polarization gradient hole nerve conduit are as follows:

[0032](1) Place β-tricalcium phosphate (β-TCP) powder (10-100nm) in an alumina ring with a diameter of 2 cm and a height of 0.5 cm, under the action of a 2kvcm-1 DC electric field, electrode in air at 100°C After 1 hour of chemical reaction, the electrodeposited β-TCP was obtained, which was taken out for later use;

[0033] (2) At room temperature, using ethyl acetate as a solvent, add polylactic acid (PDLLA) and electropolarized β-TCP respectively to make a mixed solution of polylactic acid with a mass concentration of 5% and electropolarized β-TCP with a mass concentration of 5%. ;

[0034] (3) Use magnetic stirring to completely disperse the above mixed solution, then slowly pour the mixed solution into a glass mold, at room temperature, use the solvent evaporation method for 12 hours, vacuum dry for 12 hours, and then peel off the core material...

Embodiment 2

[0038] The preparation steps of the three-dimensional bionic electric polarization gradient hole nerve conduit are as follows:

[0039] (1) Place β-tricalcium phosphate (β-TCP) powder (10-100nm) in an alumina ring with a diameter of 4 cm and a height of 1.5 cm. Under the action of a DC electric field of 5kvcm-1, the electrode is placed in the air at 200°C After 2 hours of chemical reaction, the polarized β-TCP was obtained, and it was taken out for later use;

[0040] (2) At room temperature, using chloroform as a solvent, add polylactic acid (PDLLA) and electropolarized β-TCP respectively to prepare a mixed solution of polylactic acid with a mass concentration of 10% and electropolarized β-TCP with a mass concentration of 6%;

[0041] (3) Use magnetic stirring to completely disperse the above mixed solution, then slowly pour the mixed solution into a glass mold, at room temperature, use the solvent evaporation method for 24 hours, vacuum dry for 24 hours, and then peel off th...

Embodiment 3

[0045] The preparation steps of the three-dimensional bionic electric polarization gradient hole nerve conduit are as follows:

[0046] (1) Place β-tricalcium phosphate (β-TCP) powder (10-100nm) in an alumina ring with a diameter of 6 cm and a height of 2 cm, under the action of a DC electric field of 8kvcm-1, electrode in air at 300°C After 1 hour of chemical reaction, the electrodeposited β-TCP was obtained, which was taken out for later use;

[0047] (2) At room temperature, using acetone as a solvent, add polylactic acid (PDLLA) and electropolarized β-TCP respectively to prepare a mixed solution of polylactic acid with a mass concentration of 15% and electropolarized β-TCP with a mass concentration of 8%;

[0048] (3) Use magnetic stirring to completely disperse the above mixed solution, then slowly pour the mixed solution into a glass mold, at room temperature, use the solvent evaporation method for 36 hours, vacuum dry for 36 hours, and then peel off the core material fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com