Preparation method of licorice particles for livestock and poultry

A technology of licorice and granules, which can be applied to medical preparations with no active ingredients, medical preparations containing active ingredients, and devices for making medicines into special physical or ingestible forms. There are many problems such as loss of components and prolonging the extraction time, so as to save power energy, facilitate leaching, and increase the amount of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

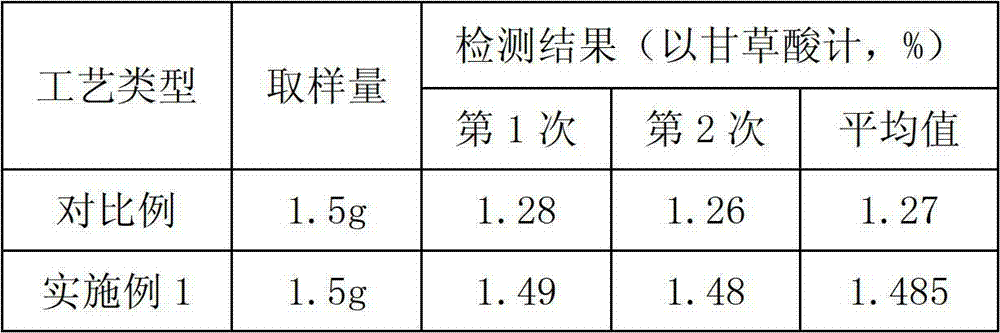

Embodiment 1

[0018] The licorice granules for livestock and poultry in this example are prepared from 100 parts of licorice, 20 parts of anhydrous glucose, and 60 parts of maltodextrin as the main raw materials. The specific preparation method is as follows:

[0019] 1) Take 100 parts of licorice, clean them, chop them and place them in an extraction tank to form a medicinal material layer, add water 8 times the weight of licorice to cover the medicinal material layer and soak for 2 hours, then adjust the working temperature of the extraction tank to 60°C for extraction. During the process, part of the extract is extracted from the bottom of the extraction tank for concentration under reduced pressure. The concentration temperature is 50°C. The steam generated by the concentration is condensed and returned to the extraction tank as a new solvent for percolation and extraction of the medicinal material layer. This is repeated for 2 hours, and finally Concentrate to obtain a liquid extract wi...

Embodiment 2

[0024] The licorice granules for livestock and poultry in this example are prepared from 120 parts of licorice, 25 parts of anhydrous glucose, and 70 parts of maltodextrin as main raw materials. The specific preparation method is as follows:

[0025] 1) Take 120 parts of licorice, clean them, chop them and place them in an extraction tank to form a medicinal material layer, add water 9 times the weight of licorice to cover the medicinal material layer and soak for 1.5 hours, then adjust the working temperature of the extraction tank to 70°C for extraction. During the process, part of the extract is extracted from the bottom of the extraction tank for concentration under reduced pressure. The concentration temperature is 60°C. The steam generated by the concentration is condensed and returned to the extraction tank as a new solvent for percolation and extraction of the medicinal material layer. This is repeated for 2.5 hours, and finally Concentrate to obtain a liquid extract wi...

Embodiment 3

[0030] The licorice granules for livestock and poultry in this example are prepared from 150 parts of licorice, 10 parts of anhydrous glucose, and 50 parts of cyclodextrin as main raw materials. The specific preparation method is as follows:

[0031] 1) Take 120 parts of licorice, clean them, chop them and place them in an extraction tank to form a medicinal material layer, add water 10 times the weight of licorice to cover the medicinal material layer and soak for 2.5 hours, then adjust the working temperature of the extraction tank to 80°C for extraction. During the process, part of the extract is extracted from the bottom of the extraction tank for concentration under reduced pressure. The concentration temperature is 70°C. The steam generated by the concentration is condensed and returned to the extraction tank as a new solvent for percolation and extraction of the medicinal material layer. This is repeated for 3 hours, and finally Concentrate to obtain a liquid extract wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com