High-rate performance vanadium-doped lithium iron silicate anode material and preparation method thereof

A technology of lithium iron silicate and cathode material, applied in the field of electrochemical power supply, can solve the problems of low electronic conductivity and low lithium ion diffusion coefficient, and achieve excellent high rate performance, high reversible capacity, and improved intrinsic conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: First set V 2 o 5 or NH 4 VO 3 Dissolved in oxalic acid alcohol solution at 80°C, oxalic acid is used as a complexing agent and ethyl silicate hydrolysis catalyst, and then lithium salt, iron salt, and silicon source are mixed in the alcohol solution to control the molar ratio of lithium, iron, vanadium, and silicon 2:0.99:0.01:1, and added to the above solution, transferred to the reflux system at 80°C for 6h, the powder obtained after evaporating alcohol and glucose were ball milled in acetone medium for 6h, and the precursor obtained after drying powder. The precursor is sintered in a nitrogen atmosphere in a tube furnace at a temperature of 650°C and kept at a constant temperature for 10 hours. After the obtained active material powder is passed through a 300-mesh sieve, it is mixed with acetylene black and polyvinylidene fluoride (PVdF) at a mass ratio of 8:1:1. Make a slurry in N-methylpyrrolidone (NMP) medium, coat it on an aluminum foil, and make ...

Embodiment 2

[0036] Example 2. First set V 2 o 5 or NH 4 VO 3 Dissolved in oxalic acid alcohol solution at 80°C, oxalic acid is used as a complexing agent and a catalyst for the hydrolysis of ethyl silicate, and then lithium salt, iron salt, and silicon source are mixed in the alcohol solution to control the molarity of lithium, iron, vanadium, and silicon The ratio is 2:0.97:0.03:1, added to the above solution, transferred to the reflux system at 80°C for reflux for 6 hours, the powder obtained after evaporating alcohol and glucose were ball milled in acetone medium for 6 hours, and the precursor powder was obtained after drying . The precursor is sintered in a nitrogen atmosphere in a tube furnace at a temperature of 650°C and kept at a constant temperature for 10 hours. After the obtained active material powder is passed through a 300-mesh sieve, it is mixed with acetylene black and polyvinylidene fluoride (PVdF) at a mass ratio of 8:1:1. Make a slurry in N-methylpyrrolidone (NMP) m...

Embodiment 3

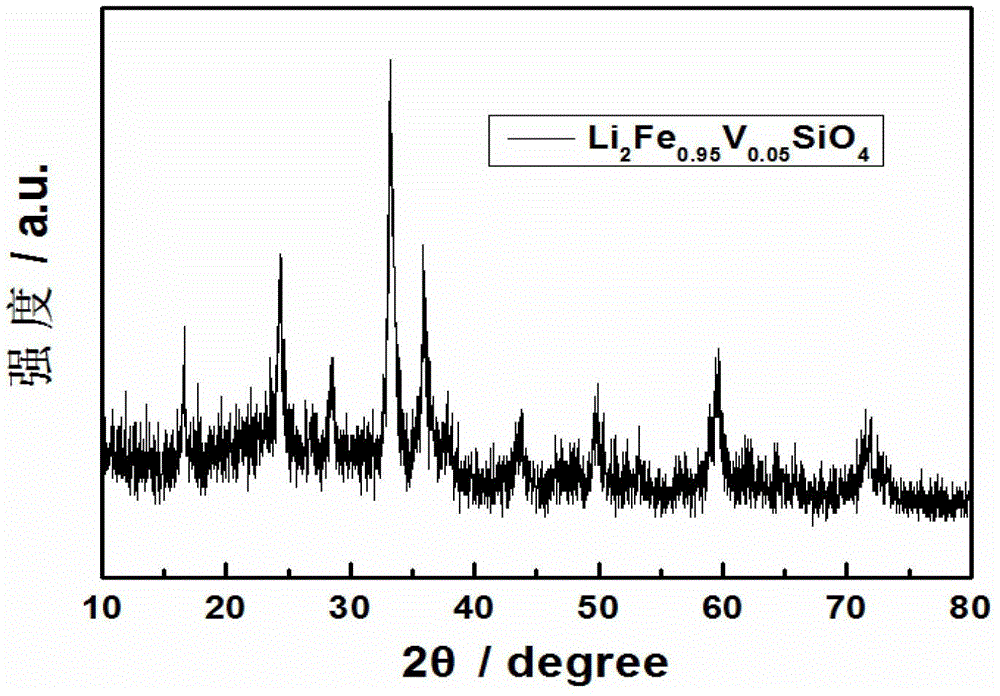

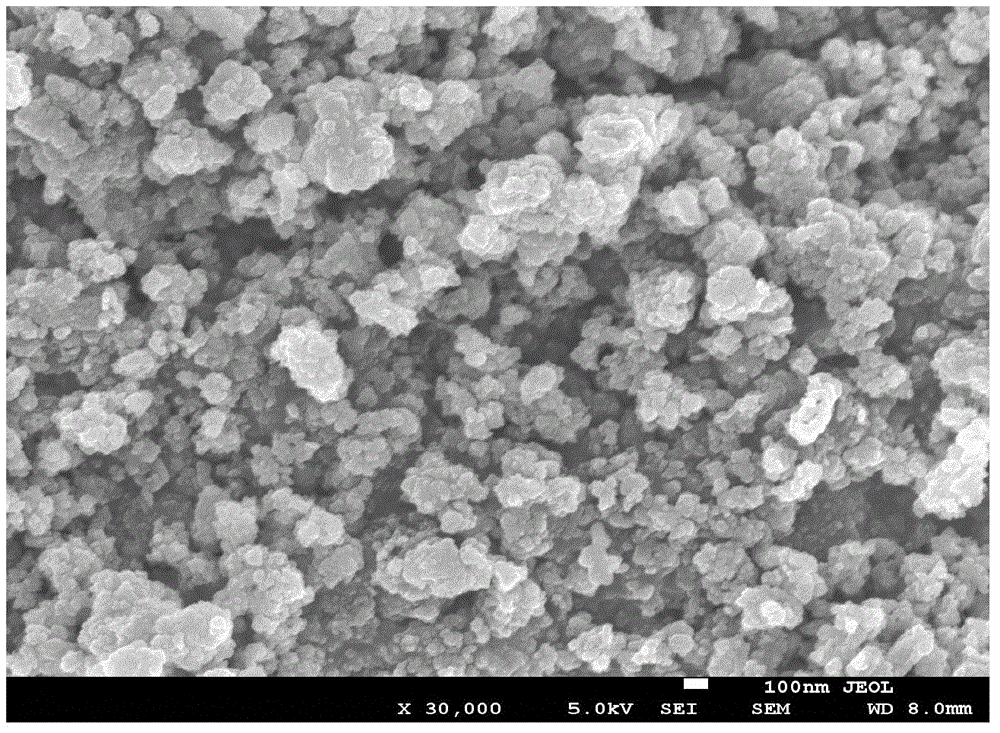

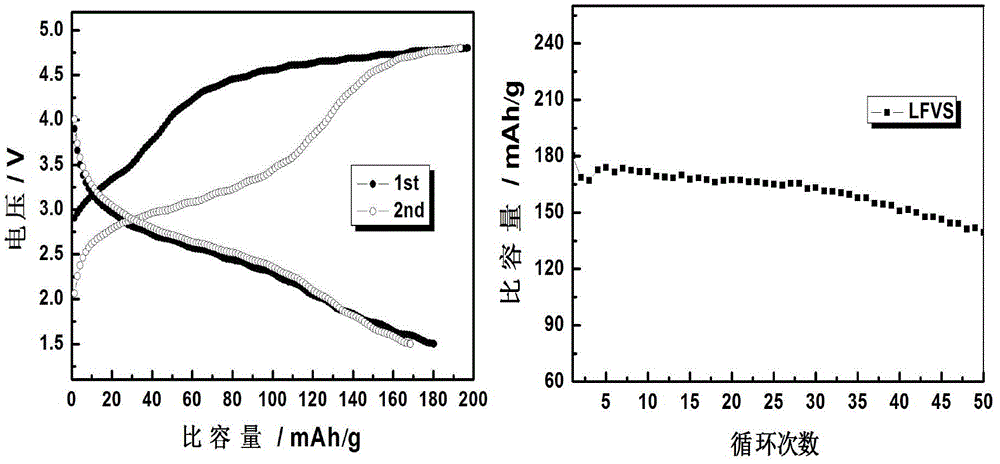

[0037] Example 3.: first V 2 o 5 or NH 4 VO 3 Dissolve in oxalic acid alcohol solution at 80°C, oxalic acid is used as complexing agent and catalyst for hydrolysis of ethyl silicate, and then lithium salt, iron salt, and silicon source are mixed in alcohol solution. Control the molar ratio of lithium, iron, vanadium, and silicon to 2:0.95:0.05:1, add it to the above solution, transfer it to a reflux system at 80°C for 6 hours, and ball mill the powder obtained after evaporating alcohol with glucose in an acetone medium 6h, the precursor powder was obtained after drying. The precursor is sintered in a nitrogen atmosphere in a tube furnace at a temperature of 650°C and kept at a constant temperature for 10 hours. After the obtained active material powder is passed through a 300-mesh sieve, it is mixed with acetylene black and polyvinylidene fluoride (PVdF) at a mass ratio of 8:1:1. Make a slurry in N-methylpyrrolidone (NMP) medium, coat it on an aluminum foil, and make a wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com