Preparation method for graphene nanosheet/conducting polymer nanowire composite material

A technology of graphene nanosheets and conductive polymers, applied in circuits, capacitors, electrical components, etc., can solve the problems of reducing charge and discharge cycle stability, reducing polymer capacitance stability, etc., and achieve excellent conductivity and chemical stability , improve electrical properties and stability, and facilitate mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

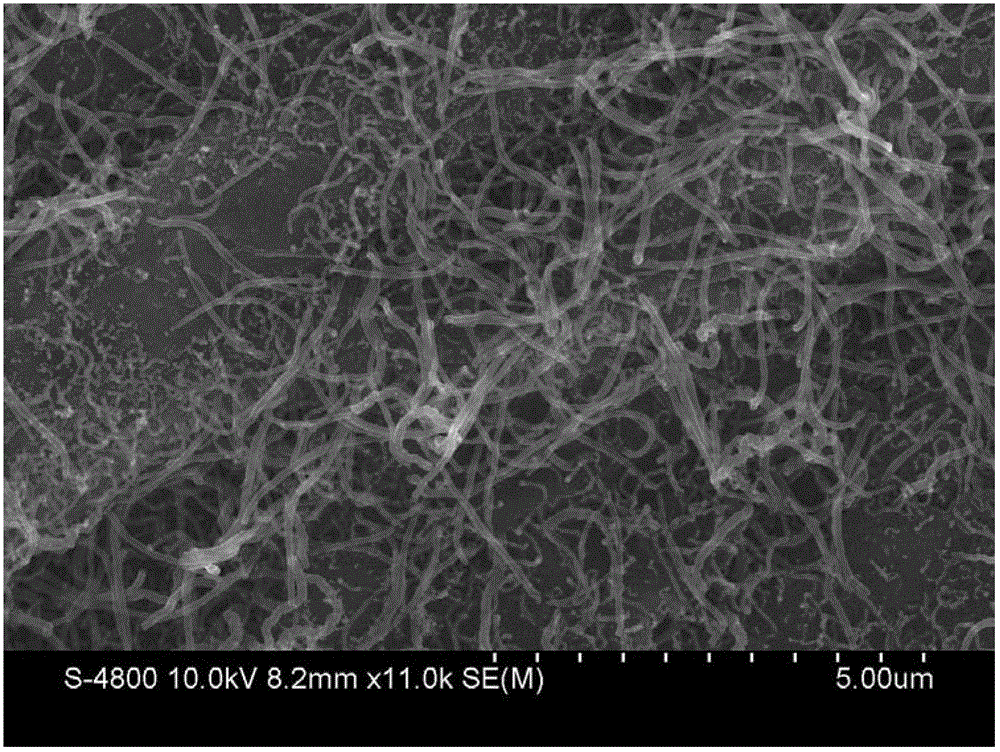

[0019] Embodiment 1. Graphene nanosheet / conductive polypyrrole nanowire composite material

[0020] The flake graphite was prepared into graphite oxide by chemical oxidation method, graphite oxide was peeled off ultrasonically in 500mL deionized water to obtain graphene oxide suspension, the pH value was adjusted to 9~10 with sodium hydroxide, and 1.8g sodium borohydride was added to graphite oxide olefin suspension, stirred at 80°C for 1 hour, then vacuum filtered and washed. The sample obtained above was dispersed in 500 mL of deionized water, 0.75 g of anthranilic acid was added thereto, and stirred at 0° C. for 5 hours. Add 5 mL of hydrazine hydrate to the anthranilate-sulfonated graphene oxide suspension, stir at 95°C for 12 hours, then wash with absolute ethanol and deionized water several times, filter with suction, and dry in vacuo. The resulting product was ultrasonically dispersed in deionized water to obtain an anthranilate-sulfonated graphene suspension. Characte...

Embodiment 2

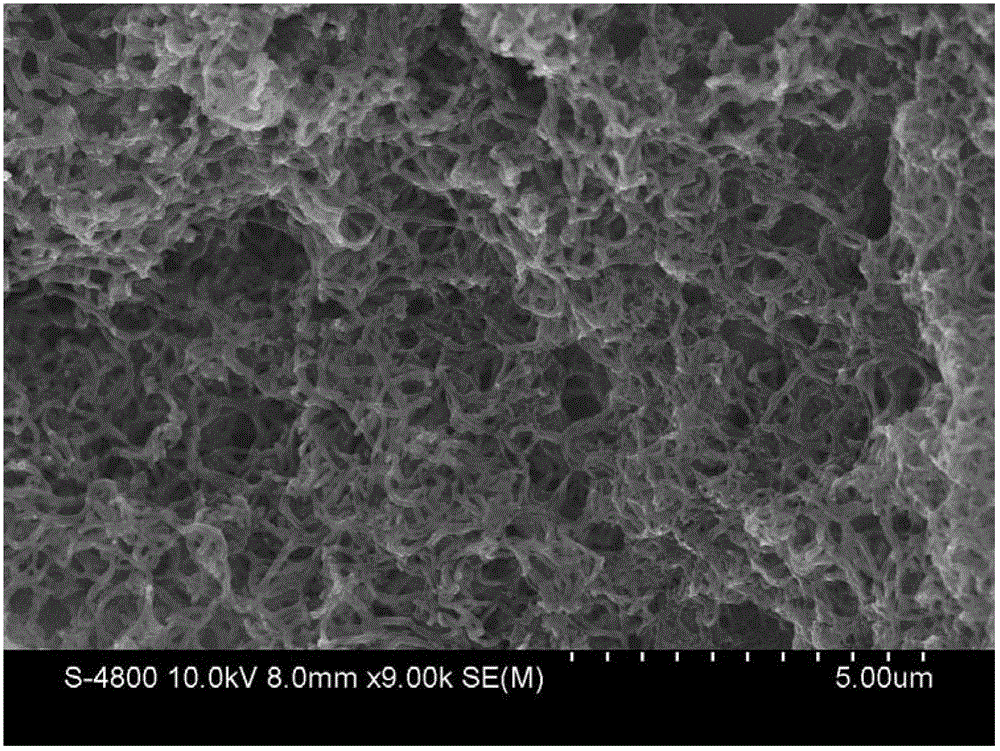

[0022] Embodiment 2. Graphene nanosheet / conductive polypyrrole nanowire composite material

[0023] The preparation method of anthranilinesulfonated graphene suspension (concentration 1mg / mL) is as shown in Example 1. The prepared anthranilic sulfonated graphene suspension was uniformly coated on the surface of a stainless steel electrode by spin coating method, and a thin film was formed after vacuum drying, which was used as a working electrode. The method for electrodepositing polypyrrole is the same as that shown in Example 1 to obtain a graphene nanosheet / conductive polypyrrole nanowire composite material. Conductive polypyrrole nanowires with a diameter of 95 nm can be uniformly dispersed on graphene sheets.

Embodiment 3

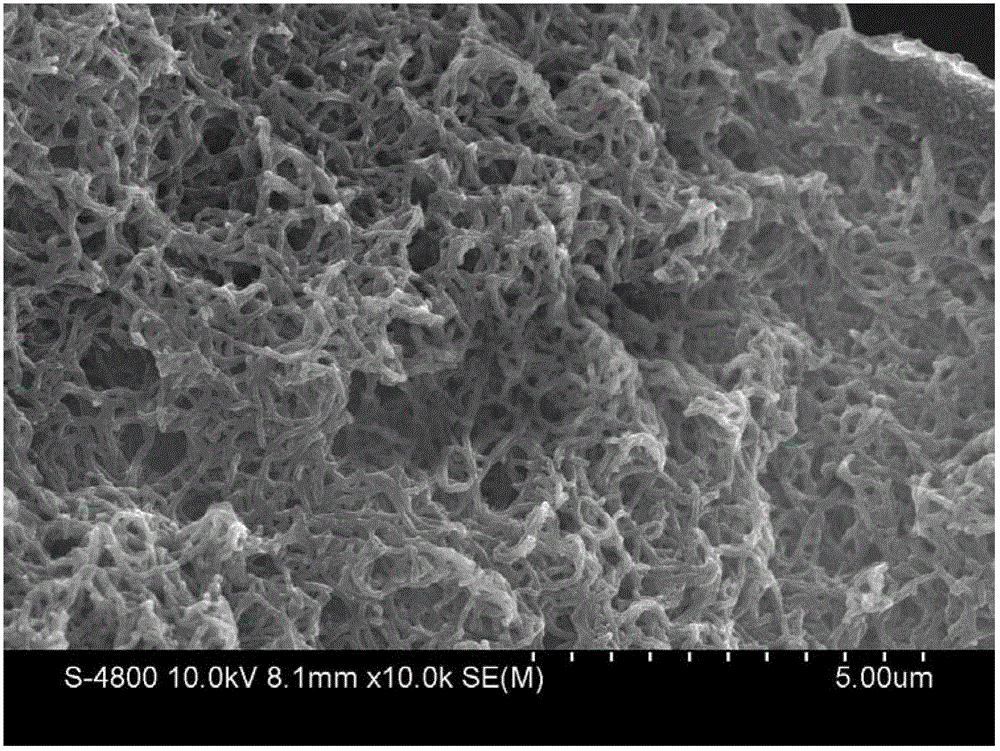

[0024] Embodiment 3. Graphene nanosheet / conductive polypyrrole nanowire composite material

[0025] The preparation method of anthranillin sulfonated graphene suspension (concentration 3mg / mL) is as shown in Example 1. The prepared anthranilic sulfonated graphene suspension was uniformly coated on the surface of a stainless steel electrode by spin coating method, and a thin film was formed after vacuum drying, which was used as a working electrode. The method for electrodepositing polypyrrole is the same as that shown in Example 1 to obtain a graphene nanosheet / conductive polypyrrole nanowire composite material. Conductive polypyrrole nanowires with a diameter of 110 nm can be uniformly dispersed on graphene sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com