Compound sandwich light wallboard edge-jointed and butt-jointed with steel wire gauzes

A light-weight wallboard and steel wire mesh technology, applied in building components, buildings, building structures, etc., can solve the problem of poor integrity of porous and cavity light-weight wallboards, time-consuming and cumbersome construction process, poor sound insulation and heat insulation effects, etc. problem, to achieve the effect of saving the plastering process, good heat insulation effect, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The solid sound-insulating and heat-insulating lightweight wallboard of the present invention:

[0019] See attached figure 1 : Solid sound-insulating and heat-insulating lightweight wallboard, composed of cement panel layers 1 on the front and back sides, and a sandwich layer 3 filled between the two cement panel layers. Its characteristics are: between two fiber steel mesh cement panels 1 A steel wire mesh 2 is reserved on both sides for the overlapping joints of the wallboard installation; a solid polystyrene granular concrete sandwich layer 3 is filled between the two fiber steel mesh cement panels. Both sides of this light-weight wallboard are reserved except the overlapping steel wire mesh 2, also leave tenon 5 and the groove 6 that cooperates with it respectively, so that the seam connection when wallboard is installed.

[0020] Among them, the fiber steel mesh cement panel 1 is made of the following raw materials in the weight ratio: 20% asbestos ...

Embodiment 2

[0021] Embodiment 2: porous lightweight wallboard of the present invention:

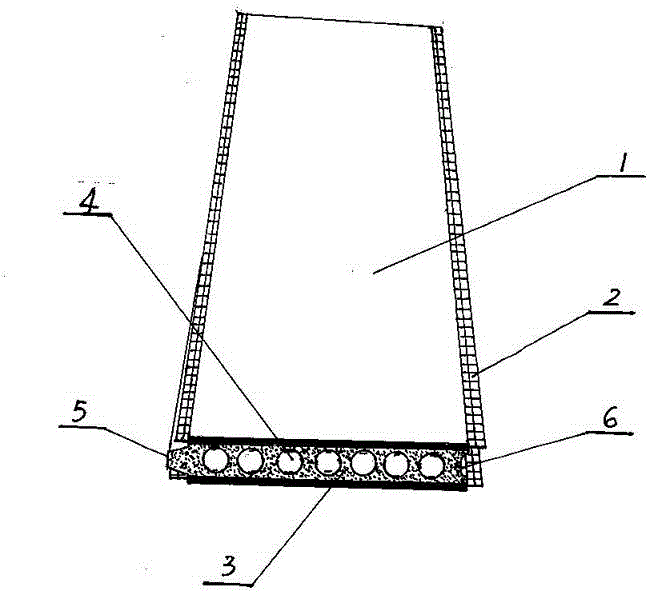

[0022] See attached figure 2 : Porous lightweight wallboard, composed of cement panel layers 1 on the front and back sides, and a sandwich layer 3 filled between the two cement panel layers. Steel wire mesh 2 is installed on the wall panels with seam overlap; between two fiber steel mesh cement panels, polystyrene granular concrete sandwich layer 3 is filled, and a plurality of hollow holes 4 are arranged in the sandwich layer 3; In addition to the overlapping steel wire mesh 2 reserved on the two sides of the lightweight wallboard, tenons 5 and grooves 6 matched therewith are reserved respectively, so as to facilitate the seam connection when the wallboard is installed.

[0023] Among them, the fiber steel mesh cement panel 1 is made of the following raw materials in the weight ratio: 30% asbestos fiber, 20% plant fiber, reinforced steel mesh with a diameter of 1.0-2.0mm, 10% stone powder and 40% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com