Method for preparing fine denier dyeable polypropylene fiber by sheath-core compounding

A polypropylene fiber and polypropylene resin technology is applied in the field of skin-core composite preparation of fine denier dyeable polypropylene fibers, which can solve the problems of spinning performance and mechanical properties decline, improve spinning processing performance, reduce melting point difference, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

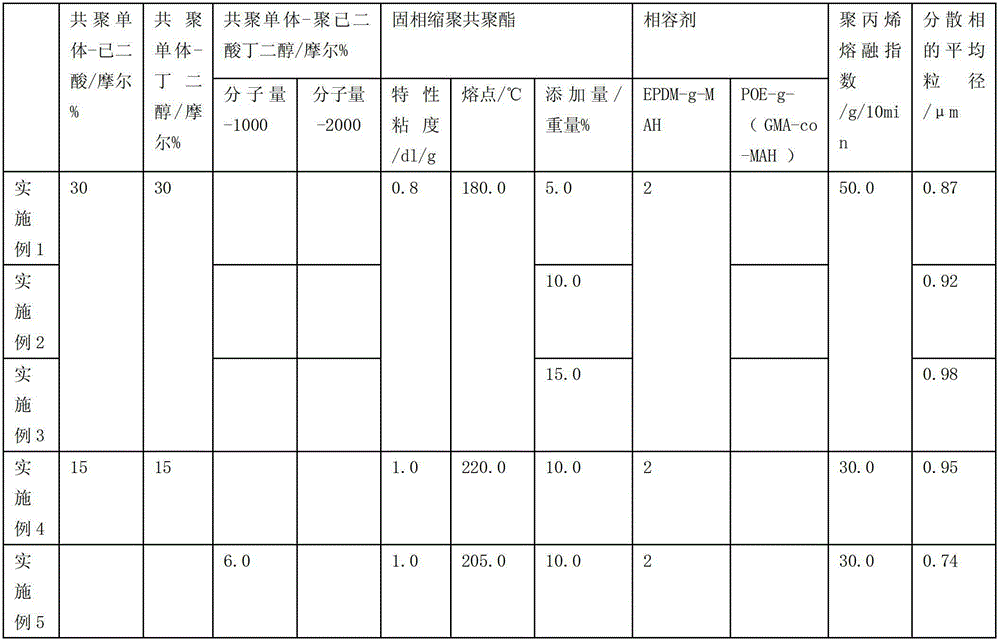

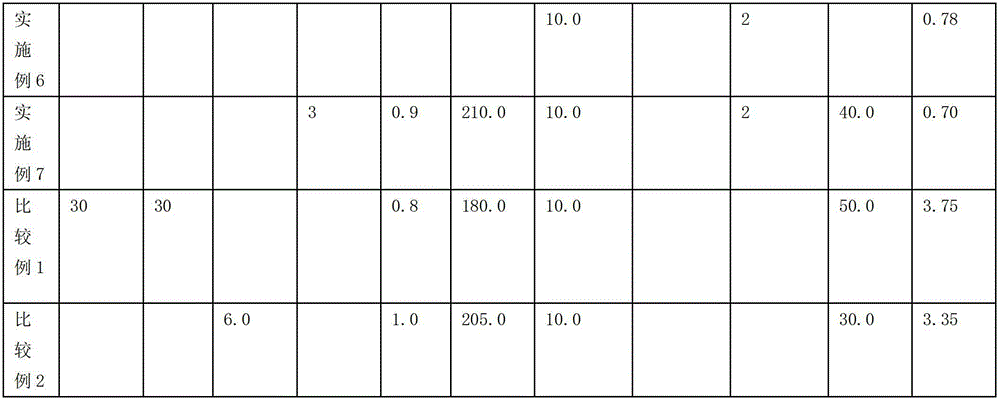

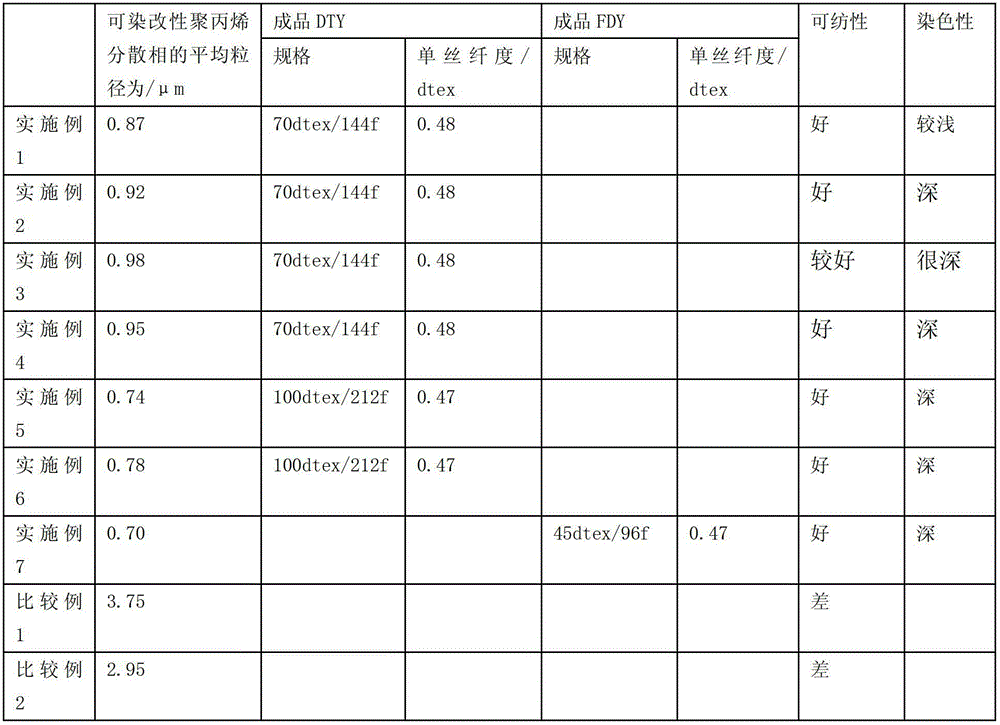

[0017] A method for preparing fine-denier dyeable polypropylene fibers by sheath-core compounding in this embodiment includes the following steps: 1) Firstly, by combining melt polycondensation and solid-state polycondensation, using terephthalic acid and ethylene glycol as raw materials , the molar ratio of terephthalic acid to ethylene glycol is 1:1.2; add adipic acid accounting for 30% of the molar percentage of terephthalic acid and 1,4 -Butanediol, to synthesize a copolyester with a melting point of 180°C and an intrinsic viscosity of 0.4dl / g; then subject the copolyester to solid-state polycondensation at 170°C and a vacuum of less than 1kpa for 36 hours to further improve its properties Viscosity increased to 0.8dl / g, copolyester additive with a melting point of 180°C; 2) The intrinsic viscosity of 5% of the total weight percentage of the additive, compatibilizer and polypropylene resin prepared in step 1) is 0.8 dl / g copolyester additive and the compatibilizer EPDM-g-M...

Embodiment 2

[0020] The preparation steps of the present embodiment are basically the same as in Example 1, except that the copolyester with an intrinsic viscosity of 0.8dl / g accounting for 10% of the total weight percentage of the additive, compatibilizer and polypropylene resin, accounting for the additive, EPDM-g-MAH with a total weight percentage of 2% of the compatibilizer and polypropylene resin and polypropylene resin with a melt index of 50g / 10min are blended and granulated at 200°C through a twin-screw extruder to obtain a dyeable Modified polypropylene resin, the measured average particle size of the dispersed phase is 0.92 μm. See Table 1, which is a table showing the preparation process and results of the dyeable modified polypropylene resin in the embodiment of the present invention. The weight ratio of skin layer to core layer is 30:70. The skin-core composite fine denier dyeable polypropylene fiber (110dtex / 144f pre-oriented yarn (POY)) was obtained. POY is then subjected ...

Embodiment 3

[0023] The preparation steps of the present embodiment are basically the same as in Example 1, except that the copolyester with an intrinsic viscosity of 15% of the total weight percentage of the additive, compatibilizer and polypropylene resin is 0.8dl / g, accounting for the additive, EPDM-g-MAH with a total weight percentage of 2% of the compatibilizer and polypropylene resin and polypropylene resin with a melt index of 50g / 10min are blended and granulated at 220°C through a twin-screw extruder to obtain a dyeable Modified polypropylene resin, the measured average particle size of the dispersed phase is 0.98 μm. See Table 1, which is a table showing the preparation process and results of the dyeable modified polypropylene resin in the embodiment of the present invention. The weight ratio of skin layer to core layer is 50:50. The skin-core composite fine denier dyeable polypropylene fiber (110dtex / 144f pre-oriented yarn (POY)) was obtained. POY is then subjected to the textu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com