Preparation method of modified polypropylene resin for superfine-denier dyeable polypropylene fiber

A technology of polypropylene resin and ultrafine denier, which is applied in the field of preparation of modified polypropylene resin for dyeable polypropylene with ultrafine denier, which can solve the problems of spinning performance, mechanical property decline, failure to produce normal mechanical properties, and no application value, etc. Problems, achieve the effect of improving spinning processing performance, improving dispersion effect, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of a modified polypropylene resin for ultra-fine denier dyeable polypropylene in this embodiment includes the following steps: 1) Firstly, through the method of combining melt polycondensation and solid-state polycondensation, using terephthalic acid and ethylene glycol as the Raw materials, the molar ratio of terephthalic acid to ethylene glycol is 1:1.2; add 30% of the molar percentage of terephthalic acid and 30% of the molar percentage of terephthalic acid 1,4-butanediol , through the method of melt polycondensation, a copolyester with a melting point of 180°C and an intrinsic viscosity of 0.4dl / g was obtained; then, the copolyester was subjected to solid-state polycondensation at 170°C and a vacuum of less than 1kpa for 36 hours to obtain Copolyester with an intrinsic viscosity of 0.8dl / g and a melting point of 180°C. 2) Then, the copolyester additive with an intrinsic viscosity of 0.8dl / g prepared in step 1) and accounting for 5% of the tota...

Embodiment 2

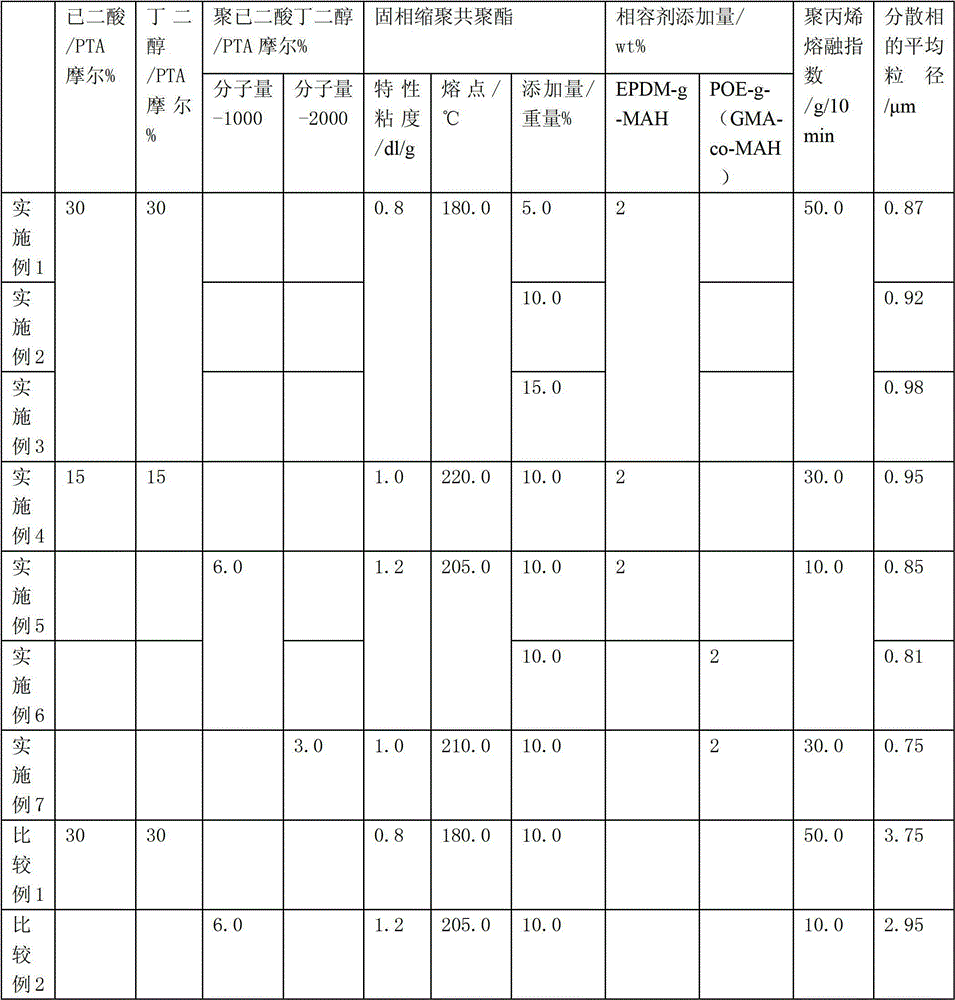

[0021] The preparation steps of the present embodiment are basically the same as in Example 1, except that the copolyester with an intrinsic viscosity of 0.8dl / g accounting for 10% of the total weight percentage of the additive, compatibilizer and polypropylene resin, accounting for the additive, EPDM-g-MAH with a total weight percentage of 2% of compatibilizer and polypropylene resin and polypropylene resin with a melt index of 50g / 10min are blended and granulated at 200°C through a twin-screw extruder, and the particle size of the dispersed phase is measured is 0.92 μm. The detailed conditions and results are shown in Table 1, which is the preparation process and result display table of the dyeable modified polypropylene resin in the embodiment of the present invention.

[0022]In this example, a copolyester containing aliphatic dibasic acid and dibasic alcohol is used as an additive, which can not only reduce the melting point difference between the additive and polypropyle...

Embodiment 3

[0024] The preparation steps of the present embodiment are basically the same as in Example 1, except that the copolyester with an intrinsic viscosity of 15% of the total weight percentage of the additive, compatibilizer and polypropylene resin is 0.8dl / g, accounting for the additive, EPDM-g-MAH with a total weight percentage of 2% of compatibilizer and polypropylene resin and polypropylene resin with a melt index of 50g / 10min are blended and granulated at 220°C through a twin-screw extruder, and the particle size of the dispersed phase is measured is 0.98 μm. The detailed conditions and results are shown in Table 1, which is the preparation process and result display table of the dyeable modified polypropylene resin in the embodiment of the present invention.

[0025] In this example, a copolyester containing aliphatic dibasic acid and dibasic alcohol is used as an additive, which can not only reduce the melting point difference between the additive and polypropylene, but als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com